Nessan Cleary discusses how wide format printing is shifting from RIP-centric to integrated workflow software, centralising job management from intake to output. These advanced systems handle pre-press tasks, colour management, nesting, and RIP’ing across multiple machines for greater efficiency. The new Adobe PDF Print Engine 7.0 will drive future innovations, with companies like Caldera, Agfa, Durst, and OneVision already enhancing their offerings to automate processes and improve throughput.

Just about every wide format printer is sold with its own RIP software, and in the past this would have determined the workflow around the printer. But increasingly we are seeing workflow software come into its own to drive jobs right through all the printers and associated equipment within production.

Workflow now includes all the file management from the moment that the jobs come in and are accepted into the print queue. It allows for preflighting and automated correction, as well as colour management and trapping plus ganging multiple jobs together and nesting graphics around each other to reduce media wastage, plus of course RIP’ing those jobs for the chosen printer. This allows for centralised management of the job queue so that you can balance the jobs across multiple machines and push more jobs through to output. This centralisation is essential whether you are running several smaller printers together from the same queue, or if you have one or more high volume machines.

Adobe used the recent Fespa Global exhibition in Berlin to announce the latest version of the Adobe PDF Print Engine. This isn’t available off the shelf since it’s sold as a software development kit but it is used widely by many RIP developers as the basis for their RIP products. So it will set the agenda for much of the workflow software that will come to market in the next year or so.

Caption: Mark Lewiecki, senior product manager at Adobe. ©Nessan Cleary.

Caption: Mark Lewiecki, senior product manager at Adobe. ©Nessan Cleary.

Adobe has sought to reduce the number of processes required in prepress by moving more of these tasks directly in to the RIP. Mark Lewiecki, Adobe’s senior product manager for the Print Engine, explains: “If we can put them right in the RIP and combine them with the RIP function, there’s an opportunity to eliminate those separate steps and also do them much faster.”

This includes: better support for multicolour transparency blending; as well as for adding variable data such as barcodes and serial numbers; automatically generating bleeds; and rendering native Photoshop and Illustrator files. The new Print Engine will also automatically improve cut lines for digital cutting tables. Lewiecki explains: “The cut lines provided in a job often don’t account for the thickness of the blade or rotor, the amount of pressure, the angle, and the tolerance. And there’s a need to dilate that cut line, and that’s what we’re doing as an in-RIP function. Today, it’s often done in Illustrator, which is a manual interactive stage.”

We will start to see these features appear in software updates next year as the OEMs start working with APPE 7.0. One of those OEMs is Caldera, which sells PrimeCentre. This aims to boost print and cut workflows by automating many of the prepress tasks using recipes containing the control settings. This includes preflighting, creating cut contours and adding bleed. It also nests jobs together and can process multiple jobs together. It will work with any RIP. Caldera has recently released PrimeCentre v4, which features a centralised hub to give users access to recent projects. It also includes pre-configured templates and tutorials to help users set up their own recipes to get better results from automating the various processes together.

Caldera has also just updated its RIP to v18.1, which gains over 20 new print drivers. Caldera has also integrated disk overload prevention directly into the RIP to prevent hard drives becoming clogged up with files from old jobs. There are extra features for subscribers, who can now import and export Hotfolder configurations across different workstations. Arnaud Fabre, head of Product at Caldera, commented: “With new tools to streamline configuration and automate job cleanup, we’re giving our users the ability to run more efficient, reliable workflows.”

Caption: Agfa’s Asanti workflow uses a browser-based dashboard.

Caption: Agfa’s Asanti workflow uses a browser-based dashboard.

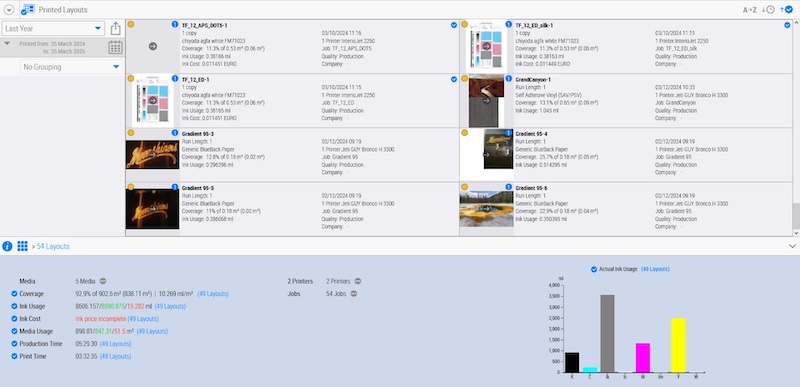

Agfa also relies on the Adobe PDF Print Engine for its Asanti wide format workflow. Asanti’s main advantage lies in its colour management, born out of Agfa’s long heritage in film and colour photography. It uses a patented Calibrated Print Mode to help users calibrate and profile media, and smart algorithms to reduce ink consumption. It includes automated preflighting and Autocollect, which intelligently groups incoming print jobs based on media type and required print quality. There’s a browser-based Production Dashboard reporting tool that allows users to inspect the status, ink and media consumption, and printing time of jobs.

The latest edition, Asanti v7, has gained a sustainability tracker that highlights how decisions made around each job contribute to its environmental footprint through items such as the material used and the energy consumption. This now includes an integration with Dataline’s Multipress MIS that gives users more detailed information to allow them to calculate the carbon footprint for each job.

Durst has built up a modular software offering to support its printers in all the sectors that it covers including large format, but also labels and packaging.

Caption: Michael Deflorian, head of Durst’s software division. ©Nessan Cleary

Caption: Michael Deflorian, head of Durst’s software division. ©Nessan Cleary

The company has developed a single core workflow that can be used in these different markets. Michael Deflorian, head of Durst’s software division, says that Durst takes quite an open approach in the wide format and graphics market, but that it’s more controlled in the labels and packaging markets.

He explains: “Our workflow has three different parts. The prepress is one and the next part is related to production, with colour management, RIP’ing and so on. And then there is the Lift ERP which can be connected to any RIP.” He says that customers can take just the parts that they want, noting: “We have customers with Lift who don’t have any relationship with Durst.”

Caption: OneVision’s workflow targets specific markets including wide format printing. ©Nessan Cleary.

Caption: OneVision’s workflow targets specific markets including wide format printing. ©Nessan Cleary.

OneVision has developed a series of automation suites, covering different parts of the print market but including one dedicated to large format printing. They all work on the same principle – automating prepress tasks – and all share the same core code, which was updated earlier this year. This update included simplifying the way that job tickets are generated. It also included a new concept of ‘Stations’ to integrate analog machines and manual steps into digital workflows with better tracking and feedback.

The wide format suite gains also improvements in nesting with the ability to handle slight misalignment of contours in duplex printing and support for varied bleed values on a single sheet, which cut down on wasted material. The tiling function has also been improved to allow for white space on tiled objects, which can be used in post-production for gluing or welding. It is also now possible to preview the contours that a milling tool generates.

All of these improvements add up to streamlined workflow, which should lead to more throughput of jobs. Moreover, when Adobe’s PDF Print Engine v7.0 filters through to the software developers, we should see a further round of improvements to workflow software next year.

Discover the latest news surrounding automation and software by signing up for FESPA World, FESPA’s free monthly newsletter that is available in English, German and Spanish. Sign up for free here.