Nessan Cleary discusses the advantages of screen printing in comparison to digital printing. There are various special effects that can be used with screen printing that can lead to higher profits and offers an crucial selling point for your business.

All too often when we talk about the choice between different print technologies, the main issue is price per unit which mostly comes down to production volume. But whereas prices dominate the lower cost part of any market, value is also important to customers at the upper end.

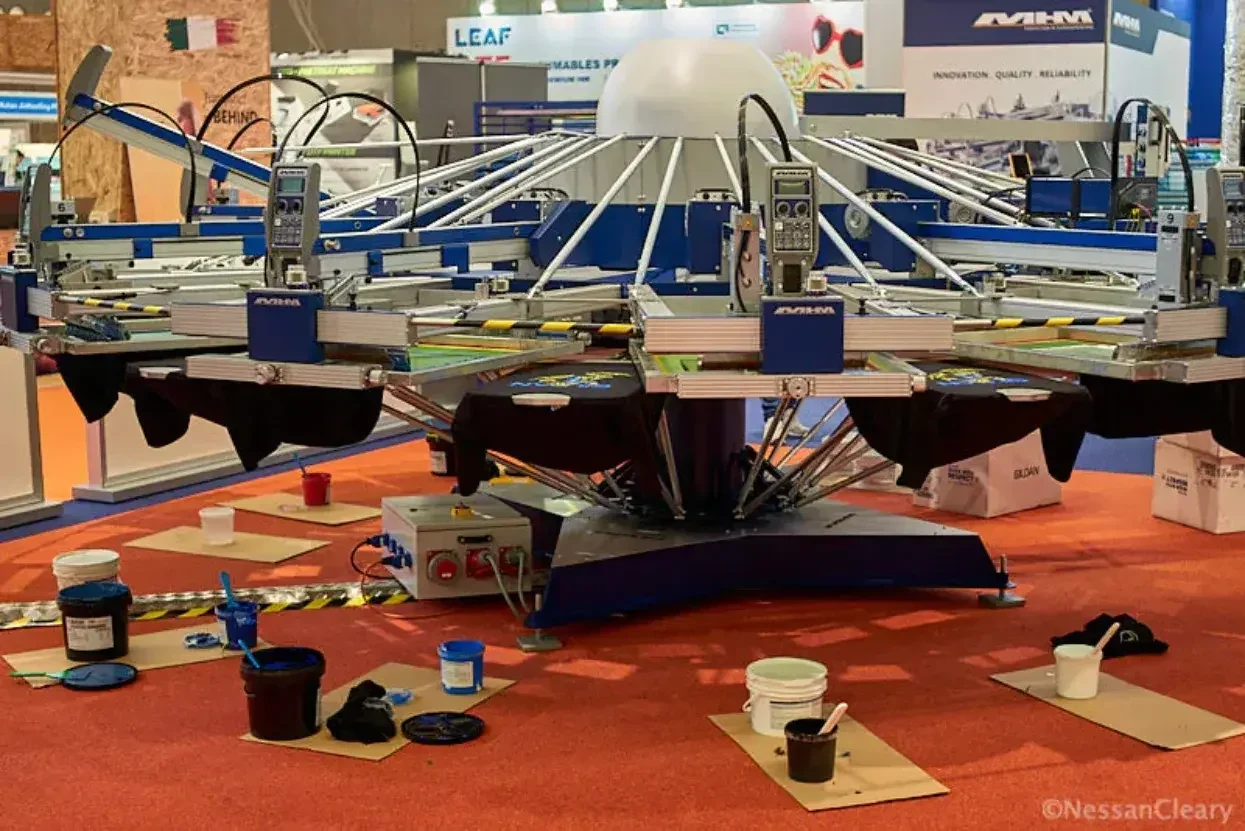

The trick of course is to increase the value, and therefore the prices you can charge, without significantly pushing up your own costs. One way to do this is to look at creative effects, and here screen printing offers a number of advantages over the digital options.

One of the simplest special effects inks is neon ink, sometimes also referred to as fluorescent ink. There are a number of different colours available, including pink, yellow and green – big bold colours that really stand out. As an added bonus, this ink will also glow under UV light, making it ideal for music themed designs for festivals or clubbing.

Another option is to use metallics to create shimmering effects. Metallic inks contain small metallic particles that catch and reflect light. These particles are a challenge for digital printers, because the particles can clog up the printhead nozzles but that’s not a concern for screen printing. Consequently metallic inks for screen printing can give a much more dynamic effect than most inkjet systems are capable of achieving. You can start with gold, silver or copper metallics and combine these with other shades. But a single metallic ink on its own can also produce a stunning effect with a reasonably high profit margin.

A variation on this is pearl ink, sometimes referred to as shimmer ink, which is a very subtle form of metallic that produces a shimmery pearlescent effect.

An increasingly popular alternative is to use foil. In this case, you print an adhesive to the material and then apply the foil, followed by pressure from a heat press to sparate the foil from its release liner After this you can remove the excess foil. It’s best to use a foil material that’s designed for screen printing to achieve a clean removal.

Reflective inks are often used for safety clothing, including sportswear for runners and cyclists, but can also add an extra degree of interest to other designs. Similar to metallic ink, it incorporate reflective particles that are designed to pick up focussed light beams such as a headlight rather than ambient light.

Then there is glow in the dark ink, which works by first absorbing the energy from light waves that is then released in darkness. The effect works best if its reasonably subtle, but the more ink that you print, the more light energy that it will hold, and consequently the longer that the glow effect will last for.

Separate to glow in the dark ink, there is black light ink, which will glow under black light. This effect works best on a dark material, and the ink will appear white under normal light. Black light is only used in certain venues such as night clubs but this ink can be highly effective in those locations.

You can add an extra dimension through the use of textured effects. One way to do this is by adding flock, which gives a garment a slightly fuzzy feel. The flock itself is just tiny textile particles, such as cotton, nylon or polyester. The idea is to print the desired colour, then add an adhesive layer. The tricky part then is to add a static charge before applying the flock. The final texture depends on the type of flock used.

There are also several inks that can create textured effects, and which can also be an effective alternative to using embroidery. A good example of this is puff ink, so called because it contains particles that expand when heat is applied, causing the ink to puff up to produce a textured 3D effect. Depending on the amount of ink you use, you can control the degree to which it expands to create a subtle texture or the full puff effect. The temptation is to use this ink throughout a design to create a very bold graphic but limiting the puff ink to certain aspects of the design can emphasis that element in a very unique way. The same effect is also available as an additive that can be mixed with a standard water-based ink.

An interesting variation on this is suede ink which contains tiny fibres suspended within the ink and results in a texture like velvet or suede that will contrast nicely with a garment’s fabric. You can limit the suede ink to emphasis certain design elements, but you can use light and dark shades to create gradient effects. Suede ink is usually only available in black or brown shades.

Another textured effect is the use of Gel ink, which can produce a 3D wet-look effect. The gel can be applied as a very thick element in its own right within a design, perhaps as a logo or text. In this case it has to be printed through a thick capillary film stencil. However, you can also apply the gel as a thinner layer on top of other parts of the design to emphasise and add a gloss look to that design.

Finally, there’s a range of chromic inks where effects are triggered by external factors and which can be used on different substrates. This includes thermochromic, where heat causes a change within the ink, typically from clear to a colour. This is the same effect that’s used mugs, where a design appears when you pour a hot drink into the mug to warm it up. These inks can achieve a similar effect on garments, triggered by body heat or by direct sunlight. Photochromic inks react to UV light, including sunlight, while hydrochromic inks react with water.

In conclusion, these special effects generally require more expensive inks, and may take longer to produce. In most cases there’s also a degree of learning to fully master them. However, such effects can command much higher prices. The trick is to use the effects sparingly, which should also help lower your costs, and if anything will increase the perceived value, leading to higher profits. More importantly, the ability to offer such effects is an important selling point for the business as a whole.

To discover the latest content that covers a wide range of sectors including screen printing, sportswear and garment printing sign up for FESPA’s free monthly newsletter FESPA World available in English, Spanish and German.