How to print directly onto bottles and other cylindrical objects

Nessan Cleary discusses the advantages and challenges regarding directly printing on cylindrical objects such as glasses and drink bottles.

Large format print technology lends itself to printing direct to flat objects, such as mobile phone cases, and we’ve already looked at some of these Direct-to-Object or DtO solutions earlier this year. However, it’s much trickier to print direct to cylindrical objects such as glasses and drinks bottles, which is sometimes also known as Direct-to-Shape or DtS.

For this reason, the conventional solution has been to print a label or shrink sleeve and then apply this to the object, and this still remains a very effective and widely used approach. However, there are several advantages to printing direct to these objects.

Firstly, it saves on time and materials because you don’t need the secondary step of applying the label or sleeve. And it’s arguably more sustainable as there’s a lot of plastic used in shrink sleeves as well as many labels. When it comes to recycling, there’s no need to remove these films from the object. However you do have to ensure that the inks used in direct printing don’t interfere with any recycling downstream.

Another advantage is that ink that bonds firmly to an object makes for a much longer lasting solution, which can add more value to certain products, such as metal or plastic drinks bottles that will have to go through many dishwasher cycles. It’s also possible to build up the ink layers on that object to create more textured and tactile effects. This can be particularly effective on glass drinkware and can add considerable value.

However, there are a number of challenges in printing direct to cylindrical objects. Perhaps the most obvious of these is the need to maintain a close and consistent distance between the printheads and the object, while also being able to print all the way around that object. Most DtO printers get around this by rotating the objects past the printheads, which slows down the printing time. This also limits the size of the objects that each printer can handle, so that such DtO printers tend to be optimised for particular applications.

Another issue is that many cylindrical objects do not have a consistent circumference from top to bottom, but are often tapered. This changes the time needed to rotate that part of the object past the printheads, and affects the standoff distance between the object and the printheads, and therefore the print quality. Most solutions that claim to be able to handle tapered objects will have a limit to how much of a taper they can cope with. As a result you will have to check both the size and the shape of any print applications before investing.

Then there is the ink itself. Most DtO printers use UV-curable ink because of its ability to bind to most materials. However, many cylindrical objects tend to have very smooth surfaces, such as glass or metal, that make it hard for the ink to bind to the surface. Some machines use a primer but most rely on the ink formulation, which will inevitably work better with some materials than others. A primer will help expand the material range, depending on the primers that are available. More importantly, a primer will also improve the durability of the graphics, which is an important consideration for drinkware that might be regularly put through a dishwasher, and for metal drinks bottles that might be left to bounce around on the outside of a rucksack where they will be at risk of scratching.

Equally, some printers will also offer varnish, which can help protect the graphic. The option to add a varnish layer also opens up lots of effects, including building up layers to create a more tactile finish.

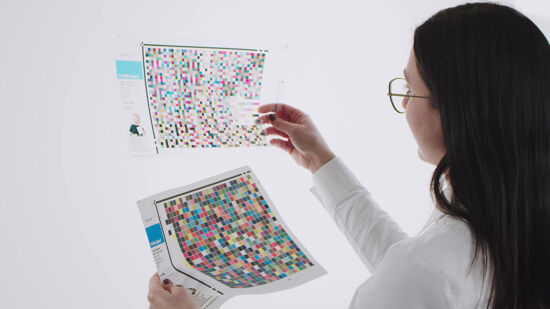

The other thing to check is the colour gamut. Most such printers only offer CMYK, which should give a good enough colour gamut for most personalisation applications. However, some brands may require orange and green to enhance their graphics for things such as promotional drinkware for fruit juices.

You should also look out for white as this will give more depth to colours printed on darker surfaces, and allow for more design options and should really be considered as a must-have for these applications.

A robotic arm is used to load and unload blank drinks bottles to this Inkcups Helix printer. ©Nessan Cleary

A robotic arm is used to load and unload blank drinks bottles to this Inkcups Helix printer. ©Nessan Cleary

There are a number of different Direct-to-Shape printers around. The American manufacturer Inkcups, for example, makes several Direct-to-Shape printers specifically for handling bottles, glasses and similar cylindrical objects. This includes the Helix One which offers a very good way of testing out this market. It’s a relatively inexpensive bench top printer that won’t take up much space. It will handle both straight-walled and tapered objects from 45mm to 116mm in height. It prints CMYK plus white and varnish and uses LED curing with UV inks.

Inkcups also sells several larger models, which all take parts up to 305mm in length but with a 218mm print area. The Helix prints CMYK plus white with optional varnish. Then there’s the Helix +, which prints on one object at a time but can be upgrade to two print station, and the Double Helix, which comes with two print stations as standard for higher productivity. Top of the range is the Revolution, which also features automatic loading and unloading to speed up the overall throughput.

Amica makes the 3Sixty range of DtS printer, which will handle bottles from 110 to 270mm in length, and diameter from 40mm to 120mm, but with a maximum print length of 220mm. The basic model has three Ricoh Gen4 printheads and will print CMYK plus white. An enhanced version has four printheads and includes varnish as well, while the top of the range model has both printer and varnish, as well as CMYK and white.

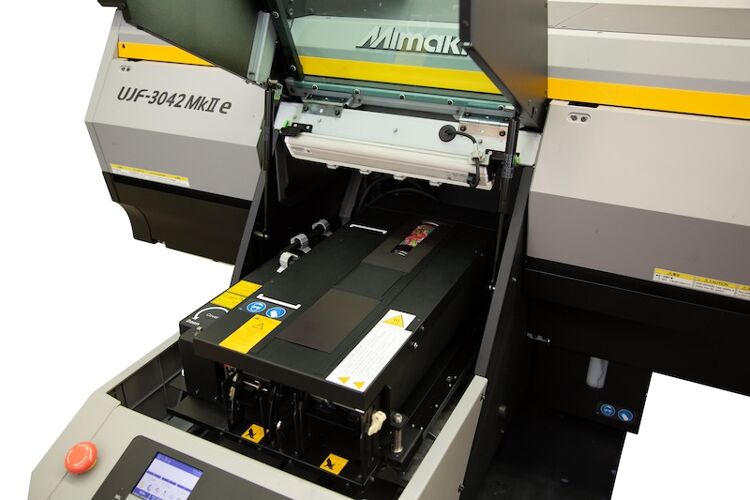

Mimaki has come up with an interesting alternative in the form of a kebab adaptor for use with its UJF series of small industrial flatbed printers, which enables printing to bottles and similar objects. Essentially it’s a jig that holds and rotates cylindrical objects to enable seamless 360 degree printing around these objects. Earlier this year Mimaki introduced a new version, the Kebab HS, which can also handle tapered objects such as glasses and cups, assuming a slope angle of up to 7.5 degrees. The Kebabs have proven popular with over 1600 already in use in the EMEA region. Mimaki estimates that one in five customers who operate a UJF printer also have a kebab unit to go with it.

In conclusion, there is enormous scope for short run production to bottles, glasses, candle holders and other cylindrical shapes. This ranges from personalised gifts through to restaurants and corporate branding. The main limitation is to choose applications that will have a similar size and shape, and to be sure that the inks have the durability and colour gamut expected of those applications.

To discover the latest content that covers a wide range of sectors including substrates, digital printing and colour management sign up for FESPA’s free monthly newsletter FESPA World available in English, Spanish and German.

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

What is the difference between labels and packaging regarding narrow web printing?

Nessan Cleary shares how labelling has always been distinct from packaging but increasingly lines are becoming blurred between them.

Shaping the future of colour measurement with Barbieri Electronic

Debbie McKeegan speaks to Viktor Lazzeri, COO of Barbieri Electronic who shares his insights on the significance of accurate colour management regarding all methods of design and production.

Final call: FESPA Awards 2025 extends submission deadline to Monday 6 January 2025

FESPA has today announced an extension for speciality printers and sign makers, from across the globe, to submit their entries to the FESPA Awards 2025. Those wishing to participate now have until midnight on 6 January 2025 to submit their entry.