Why must the print industry recognise software and material innovation

Laurel Brunner argues that the printing industry must recognise the value of both software and material innovation, and be willing to pay for it. Software, though intangible, drives efficiency and reduces carbon footprints. While materials science currently dominates, R&D costs are inherent in all advancements. Paying a premium ensures continued progress, benefiting the industry's evolution and sustainability.

It’s fair to say that people of a certain age in the printing industry can get a bit confused about software. This is not surprising: software is invisible, it’s something you’re told you have to have if your platesetter is to work efficiently. Software’s vital for your digital press and you have to have it to check incoming PDFs, manage workflows and job queues etc. Information technology in general and software in particular is a facilitator. Software provides services the value of which cannot easily be quantified. This may be baffling to many printing company owners, but software efficiencies keep bringing down the carbon footprint of print through efficiency enhancements.

You pays your price and you takes your chances, so they say. Obviously the price you pay should be based on the value that tech provides to your business and what you can afford. But as well as what the product does for the money, the price you pay should reflect the value of the support and service you get from the service provider.

Software development has been the biggest concern in the prepress business for a long time and for decades we’ve been reasonable happy to pay for it. That might be because people didn’t fully understand the workings and nuances of what they were buying. After all, it’s not possible to price software by the litre or the square metre as can be done with substrates, ink and plates. But these days software advances and innovations are taking a back seat to advances in both printing plates and inks, to materials science which is also helping bring down print’s environmental impact.

A glance at the trade press will tell you materials science is definitely where all the action is. It’s easy to compare plates and inks like for like so price squabbles seem to be more common than they used to be. Bickering over the price of plates, ink or substrates is simpler with tangible materials for which the pricing should not be opaque or confusing. Materials are easier to compare than software products, but we should keep in mind that for both materials and software the cost of research and development (R&D) is built in. It was a given with software that you pay for the development of upgrades and functionality improvements and the same is true for plates, inks and substrates, especially if those improvements drive down the industry’s carbon footprint. So be prepared to pay a little more to ensure the continued evolution of the materials you buy. R&D is the only way our industry will keep evolving and moving forward, whether it’s the development of preflight software, or an as yet uninvented imaging system.

Topics

Recent news

Green Printing: how Sustainability drives business success

Nessan Cleary shares sustainable printing benefits businesses and the environment. Auditing suppliers and using eco-friendly materials are crucial. Optimising production with energy-efficient equipment and minimising waste reduces costs. Proper waste disposal and premises efficiency further lower the carbon footprint. Staff training and customer recycling solutions complete the sustainable approach.

Sustainability and keeping the faith

Laurel Brunner discusses how the printing industry has drastically reduced its environmental impact through technological advances, despite lingering perceptions of paper waste. While consumer habits pose a challenge, the industry continues to pursue greener practices.

Kyocera wins Anthem Award for Sustainability, Environment and Climate

Laurel Brunner shares how Kyocera, a Japanese manufacturer of digital printing system was awarded a silver award for its green skills report on "A Green Edge: Green Skills for the Future".

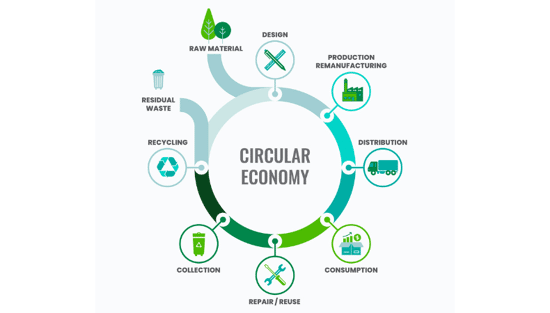

How to design for a circular economy in a linear world

Laurel Brunner explains the challenges for businesses to prioritise circular economy when economies have evolved to be linear. Laurel shares examples of different businesses who are designing products that can suppor the circular economy. These include The Ellen MacArthur Foundation, DS Smith and Vilsund Blue A/S.