A conversation with Adobe

FESPA's Textile Ambassador, Debbie McKeegan speaks to the Director of Print Technology and Strategy at Adobe.

Mike began his digital journey some three decades ago, and whilst he never envisaged himself working for Adobe, fate had a hand to play. Following a company merger Mikes roots were firmly planted in the Adobe tree and he has been with the company ever since.

Caption: A visionary and passionate technologist, Mike Scrutton now lives in Silicon Valley, California and heads up the team developing the new software Adobe Textile Designer which is currently available for free download as a public beta. Credit: Adobe.

Responsible for many groundbreaking software solutions over the years, Adobes latest addition to the Creative Suite is Textile Designer, and its set to transform the working footprint of the creative. To understand why this new tool is necessary we mused over the industry and its thirst for connectivity, design diversity, digitization and the control of colour. The ability to move between multiple platforms, using various file formats is critical, and any file, must now move seamlessly through a commercial print workflow with no human interference. To do so the industry has been challenged to capture the intentions of the designer and to integrate these actions into the manufacturing technology and digital production workflow.

A challenge which has now been overcome in the commercial print space, and where for Textiles there are many lessons that can be learned from the digitization of the paper printing industry. Inevitably the process of digitizing the Textile workflow will be accelerated by the application of this knowledge. Currently we haven’t quite achieved digitization of the Textile supply chain, which poses its own unique challenges as a sector with great diversity.

Speed of production is driving technology forward at an intensive pace, and by working in collaboration with the wider Textile manufacturing community and the technicians within, the Adobe software team are bringing down the barriers of manufacturing to achieve greater efficiency.

Caption: As we move further and further into a new manufacturing workflow, the data we create must become more sophisticated, and be both portable and multi-lingual. If we are to work in a digital world, we must all speak the same language. Credit: Adobe.

.png?lang=en-GB)

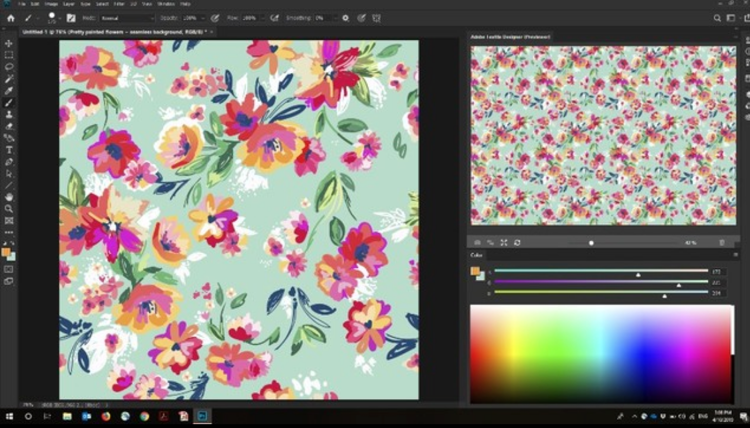

Caption: Adobe Textile Designer is built to rationalize the designer’s workflow, by creating standardized files that are capable of transporting the data, colour, scale, profiles etc in one digital file. Credit: Adobe.

The program speeds up creative efficiency by automating many of the manual processes that are a huge part of the Textile design process; repeat, colour separation and colourway generation for example can all now be created digitally and importantly, created in one software suite.

The creative workspace is increasingly freelance, and here the ability for the designer to standardize communication between the creative and manufacturing communities is a must have deliverable. If we are to manufacture sustainably, we have to remove the waste from our supply chain, and only by standardizing the process will we do so.

Colour is one of the most inefficient areas of the textile manufacturing process, and again here lessons can be learned from the commercial print industry for an end-to-end solution. There are multiple options for calibrating colour, but ultimately the process must become more automated. For Adobe and Textile Designer, Spectral Data, will become more evident over the next few years to generate a language that talks about the DNA of a colour, to define a visual colour, in a digital space, for Adobe this is now in development, so watch this space.

The textile space is a living environment that is experiencing a sea change in manufacturing practice. Digital disruption has enabled many new processes and has democratized the print space. This has led to a huge surge in entrepreneurial growth, and with it a need to move design data across the globe, whilst importantly achieving the designer’s interpretation regardless of final print destination. VR and AR software all have a part to play on this visual, digital journey, and if we are to showcase products online, the final manufactured item must be a true representation of the digital twin. Only by standardizing colour can we achieve this with no human intervention.

Democratizing the print route, has led to a huge growth in Designers makers and new Boutique designers across multiple markets, often with creatives that have no textile print experience. Standardizing the channel and simplifying the design tools with allow continued growth in the creative sector and unlimited opportunities.

As the Textile space unlocks the edges are also blurring between design disciplines, and we now see a migration of design from the Graphics industry to Textiles across multiple product sectors. Not just Textiles, Ceramics, Fashion and Homeware are often now all components of an e-commerce designer store. It is the industries challenge to define a new language that can control colour between product groups and achieve our online purchase expectations, wherever possible.

Looking to the future the industry must continue to develop smart solutions for e-commerce and print compatibility across multiple substrates and print applications.

Automation will transform the manufacturing process and allow for greater design diversity across the industry. Customization is a given for the next generation and the computerization of the manufacturing process will continue to penetrate the supply chain. Data and production data must be embedded into the print file to enable automation within the product lifecycle.

Sustainable manufacturing is of paramount importance to Adobe, and their software will ultimately continue to deliver the solutions and affordable options for best practice. Across the supply chain we all use software within our daily lives, by connecting the data infrastructure we will undoubtably strive to achieve the sustainable practice and seek to reduce the environmental harm that the textile industry currently contributes to the planet.

As digital nomads we are evolving at an incredible pace, and in summary we are at the beginning of a digital shift and a new generation of software and digital manufacturing processes.

Digital disruption has enabled a new generation to reach into the Textile space, and as an industry we welcome the exponential growth and creative democratization thanks to programs such as Adobe Textile Designer.

Listen to the corresponding podcast here.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

The importance of ink for large format printers

Ink is crucial for large format inkjet printers, influencing substrate compatibility, productivity, and cost. Nessan Cleary discusses the three main types which include UV-curable ink, latex ink and eco-solvent ink. Each ink type has specific strengths and weaknesses, making printers choice dependent on budget and intended applications.

What are the benefits of Direct-To-Fabric printing?

Direct-to-fabric printing is gaining popularity for high-volume textile production, enabling on-demand, customized short runs. These printers offer ink flexibility, accommodating various fabric types like cotton and silk, though ink development focuses on faster turnaround by reducing pre- and post-processing. Compared to traditional methods, direct-to-fabric inkjet printing is a more sustainable option due to reduced water and chemical usage, and localized production.

What are the opportunities for large format providers regarding digital touch screens?

Digital touchscreens are becoming increasingly common, offering businesses opportunities to improve customer engagement and streamline operations. Nessan Cleary shares, while more expensive to implement than standard digital displays due to complex software and integration needs, touchscreens provide self-service options, multilingual support, and can reduce staffing costs in various settings like retail, transportation, and healthcare.