Baldwin acquires PC Industries to expand

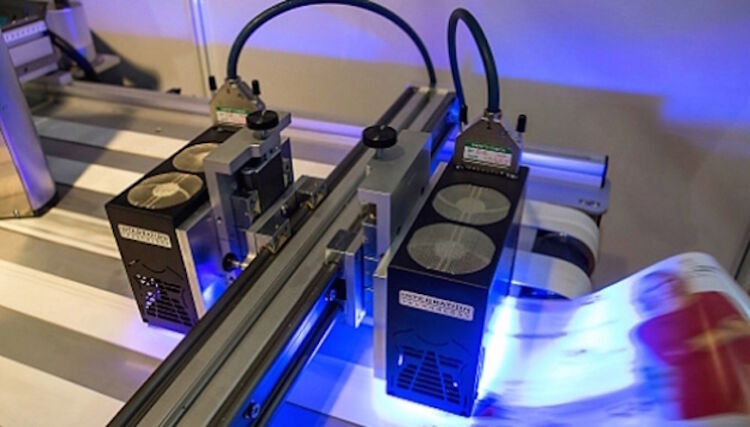

Automation systems and consumables manufacturer Baldwin has acquired vision inspection systems PC Industries.

Headquartered in Gurnee, US, PC Industries (PCI) is a leading manufacturer of state-of-the-art vision inspection systems for the printing, converting, packaging, pharmaceutical and security printing industries.Founded by Jack Woolley in 1975, PC Industries’ products are complementary to Baldwin’s offerings.

“The integration of PC Industries’ will add scale to our broader vision business by opening up new customer opportunities and enhancing our ability to provide further capabilities to our existing customers,” said Baldwin CEO Brent Becker.

PC Industries is Baldwin’s fourth acquisition since joining the BW Forsyth Partners’ family of companies in 2012. In 2014, Baldwin acquired Web Printing Controls and in January 2017, LED UV curing technology provider Air Motion Systems. Earlier this month, they completed the acquisition of Ahlbrandt Systems GmbH.

Following the AMS acquisition, a new division within Baldwin combined AMS with Baldwin’s UV division and rebranded as AMS Spectral UV.

The AMS LED UV product portfolio is used for LED curing in sheetfed offset printing and flexo packaging and the firm has a strong partnership with KBA. Baldwin claims that AMS’ installed base is nearly 10 times that of its nearest competitor.

Baldwin is part of the Barry-Wehmiller family of companies, which have a combined turnover of $2bn (£1.58bn). Baldwin’s own turnover was not disclosed but Keogh said AMS was roughly the same size and therefore Baldwin’s turnover has doubled following the acquisition.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

The importance of ink for large format printers

Ink is crucial for large format inkjet printers, influencing substrate compatibility, productivity, and cost. Nessan Cleary discusses the three main types which include UV-curable ink, latex ink and eco-solvent ink. Each ink type has specific strengths and weaknesses, making printers choice dependent on budget and intended applications.

What are the benefits of Direct-To-Fabric printing?

Direct-to-fabric printing is gaining popularity for high-volume textile production, enabling on-demand, customized short runs. These printers offer ink flexibility, accommodating various fabric types like cotton and silk, though ink development focuses on faster turnaround by reducing pre- and post-processing. Compared to traditional methods, direct-to-fabric inkjet printing is a more sustainable option due to reduced water and chemical usage, and localized production.

What are the opportunities for large format providers regarding digital touch screens?

Digital touchscreens are becoming increasingly common, offering businesses opportunities to improve customer engagement and streamline operations. Nessan Cleary shares, while more expensive to implement than standard digital displays due to complex software and integration needs, touchscreens provide self-service options, multilingual support, and can reduce staffing costs in various settings like retail, transportation, and healthcare.