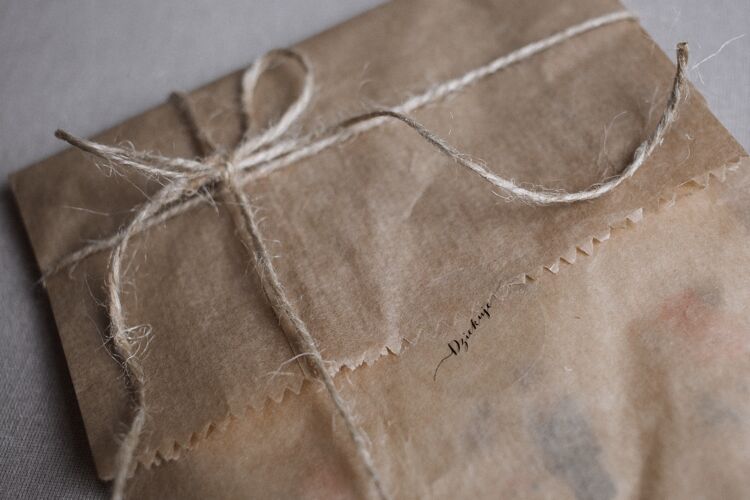

Plastic versus paper packaging

Laurel Brunner discusses the argument between plastic versus paper packaging and their effect on our environment. Can a new alternative be the answer?

Currently there’s a lot of discussion taking place regarding the negative effect of plastic packaging on the environment. On one hand there’s currently 8 million tonnes of plastic floating in our oceans. On the other hand, plastic has proven to be a very efficient packaging material especially regarding keeping food uncontaminated and fresh. Plastic also has a long shelf life and is beneficial for displaying goods and for manufacturing carrier bags. Proponents for plastic packaging for bags, bottles, wrappers, trays and tubs will inform you of this and they also claim that if a different material was used such as paper or metal that total emissions for energy and greenhouse gases would increase.

In truth it’s difficult to come by reliable data that supports this but it is accurate that plastic is light in weight therefore it does not contribute to transport costs and the associated emissions. Plastic is also reliable and durable, meaning that food waste is reduced: think plastic wrapped versus loose grapes. Nevertheless, it is also true that several products that are sold wrapped in plastic don’t require protection: think rutabagas (swedes) and coconuts. The benefits of plastic are numerous, but there’s no denying the fact that it’s overused and there are alternatives that have less of a negative effect on the environment.

Paper companies such as Stora Enso and Sappi have successfully made huge strides in developing similar alternatives that are based on wood pulp, a renewable resource which also offers an exceptional carbon capture method. Trees not only capture carbon but they also consume it through photosynthesis, a process that produces oxygen as a waste by-product. Paptic has been developed by a Finnish start-up company and it could potentially replace both plastic and paper in the future. Paptic is a paper-based material that is entirely recyclable and is well-suited with existing packaging lines. Its developers comment that it’s “the next generation of paper with all the benefits of paper combined with the fundamental properties of plastic like heat sealability.”

In response to such initiatives and consumer concerns, the plastic industry has acted to better the material’s environmental impact. Plastic is mostly made oil, therefore it’s not easy to recycle. However, some plastics can be recycled and made into new plastics whereas the rest can be incinerated to produce energy. The recyclability of plastic is dependent on its composition and the complexity of polymers involved: for example, the fewer in bottles, the better. Packages that are made from a combination of ingredients are more difficult to turn into raw material for new products.

For households in the UK that generate 1.7 million tonnes of packaging waste annually, there is currently work being done to decrease waste plastics to their components to ensure that these chemicals can be reused. This work is in its early stages and currently plastic continues to pollute the waterways and oceans.

Source: This article was produced by the Verdigris project, an industry initiative intended to raise awareness of print’s positive environmental impact. This commentary helps printing companies keep up to date with environmental standards, and how environmentally friendly business management can help improve their bottom lines. Verdigris is supported by the following companies: Agfa Graphics, Spindrift.click, EFI, FESPA, HP, Kodak, Kornit Digital, Ricoh, Splash PR, Unity Publishing and Xeikon.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Personalisation Experience returns for its third edition

Personalisation Experience is back for its third edition, taking place from 6-9 May 2025 at Messe Berlin, Germany. At the event, visitors wishing to discover the latest innovations in personalisation technology, as well as trends, will be able to explore innovations from a wide range of exhibitors and engage with thought leaders.

swissQprint to launch new flatbed range at FESPA Global Print Expo 2025

At FESPA Global Print Expo 2025 in Berlin, swissQprint will unveil its redesigned flatbed printer range, boasting a 23% output increase and 10 color channels. The Karibu roll-to-roll printer and diverse applications will also be showcased.

Global exhibitor line-up confirmed for FESPA Global Print Expo 2025 and co-located events

FESPA Global Print Expo, European Sign Expo and Personalisation Experience (6 - 9 May 2025, Messe Berlin, Germany) will welcome over 550 new and returning exhibitors from over 36 countries, already surpassing exhibitor numbers from last year’s events.

How is Smart Manufacturing Transforming Fashion and Apparel Manufacture?

Debbie McKeegan explores the paradigm shift in the fashion industry from fast fashion to personalised fashion, highlighting the technical challenges, solutions, and operational benefits for the manufacturing community. Debbie speaks to experts Oliver Mustoe-Playfair from Prinfab, Phil McMullin of Epson UK and Guy Alroy of Early Vision.