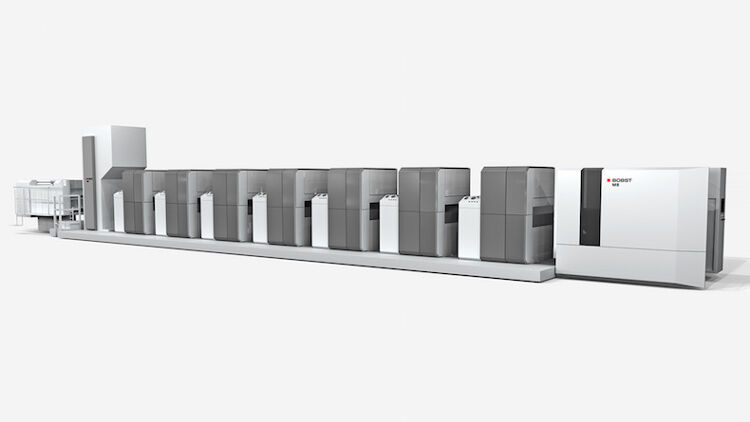

Bobst launches M8

Bobst has introduced an upgraded flexo press, the M8 flexible packaging line, targeted at label converters looking to diversify into flexible packaging.

The new M8 is intended as an upgrade on the M5 and M6 flexo presses, with improvements in speed and wider web widths, along with the ability to take materials of higher grammage.

It can print at speeds of up to 400m/min, 150m/min faster than the M6, and has a web width of up to 1.1m. It prints on a variety of substrates, including paper, foil, lamitubes and film, handling substrates of up to 600gsm, double the highest grammage of the M6.

The machine has fully automated setup utilising Bobst’s Digital Flexo technology, which allows for complete digital control of the press and camera-monitored closed loop print operations that enable fully automated pre-register.

"Most printing companies today know they need to diversify in order to grow or even maintain revenue streams, and many label printers have been adding equipment to produce short run customized packaging to complement their revenue," commented Bobst Firenze managing director Matteo Cardinotti.

"The new Bobst M8 press is uniquely suited to forward-thinking label printing companies that want to move into the flexible packaging market in a way that exceeds contingency needs to allow strong and sustainable growth in this sector."

The press prints with UV, water- or solvent-based inks on a wide range of substrates, including plastic and aluminium filmic materials, laminated tubes and paper in a roll-to-roll configuration, while a special version converts cartonboard up to 600gsm.

Alongside digital control and total colour consistency, Bobst says the M8 delivers automatic on-the-fly job changeover sequences with up to 95% press uptime.

These features enable the press to operate profitably with all run lengths, including just-in-time orders. Also, the spectrum of substrates handled by the press includes all types used in packaging reel-to-reel printing: film, aluminum foil, lamitubes and paper.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

The importance of ink for large format printers

Ink is crucial for large format inkjet printers, influencing substrate compatibility, productivity, and cost. Nessan Cleary discusses the three main types which include UV-curable ink, latex ink and eco-solvent ink. Each ink type has specific strengths and weaknesses, making printers choice dependent on budget and intended applications.

What are the benefits of Direct-To-Fabric printing?

Direct-to-fabric printing is gaining popularity for high-volume textile production, enabling on-demand, customized short runs. These printers offer ink flexibility, accommodating various fabric types like cotton and silk, though ink development focuses on faster turnaround by reducing pre- and post-processing. Compared to traditional methods, direct-to-fabric inkjet printing is a more sustainable option due to reduced water and chemical usage, and localized production.

What are the opportunities for large format providers regarding digital touch screens?

Digital touchscreens are becoming increasingly common, offering businesses opportunities to improve customer engagement and streamline operations. Nessan Cleary shares, while more expensive to implement than standard digital displays due to complex software and integration needs, touchscreens provide self-service options, multilingual support, and can reduce staffing costs in various settings like retail, transportation, and healthcare.