Carmel Frenkel targets packaging growth with EFI

Rob Fletcher speaks to Carmel Frankels who are one of the first companies to invest in the EFI ecosystem for corrugated packaging

Israeli firm Carmel Frankel has become one of the first companies in the world to invest in the complete EFI ecosystem for corrugated packaging as part of a wider effort to enhance its already-strong position in this market.

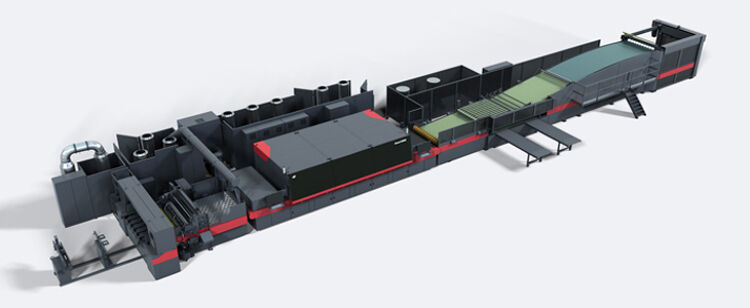

The company, a subsidiary of Hadera Paper, specialises in corrugated display and packaging, and has bought an EFI Nozomi C18000 single-pass, high-speed LED inkjet corrugated packaging press to bolster its service offering.

The press, the first to be installed in the Middle East, measures in at 1.8m wide and can run at speeds of up to 75 linear metres per minute, or 10,000 89 x 89cm boards per hour two-up. The machine is scheduled for installation in the fourth quarter of this year.

Carmel Frankel’s investment package also includes the EFI Fiery NZ-1000 digital front end (DFE), as well as the EFI Corrugated Packaging Suite manufacturing execution system (MES) business and production management workflow and EFI Escada corrugator control software.

Reflecting on the purchase, Guy Frenkel, chief executive of Carmel Frenkel, said the new technology will help the company to achieve its growth targets within the wider packaging sector.

“We are committed to staying on the leading edge of packaging technology,” Frenkel said. “That is the main reason why we went for the Nozomi press.

“We have invested considerable time and effort in evaluating the most-advanced digital corrugated technologies and, with this press, we know EFI is delivering an innovative technology that will be able to handle a variety of print jobs with faster throughput and high output quality.”

EFI said that Carmel Frankel’s decision to invest in its complete ecosystem for corrugated packaging will enhance the impact of the press.

The EFI Fiery NZ-1000 DFE print server and production system will, according to EFI, boost performance and colour quality, as well as offer the firm more production tools, enhanced job management and the ability to produce versioned/multi-SKU work or even personalised packaging at full speed.

In addition, EFI said the MES workflow will facilitate plant-wide management and integration of digital production for an end-to-end business and production framework to handle not only digital print, but analogue flexo litho-lam and litho label operations at Carmel Frankel.

José Luis Ramón Moreno, vice-president and general manager of industrial printing at EFI, added: “It is clear that the corrugated packaging market is evolving at a rapid pace and having the complete EFI ecosystem will definitely give Carmel Frenkel an innovative edge to continue to stay ahead of the market by delivering greater value to its clients.”

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

The importance of ink for large format printers

Ink is crucial for large format inkjet printers, influencing substrate compatibility, productivity, and cost. Nessan Cleary discusses the three main types which include UV-curable ink, latex ink and eco-solvent ink. Each ink type has specific strengths and weaknesses, making printers choice dependent on budget and intended applications.

What are the benefits of Direct-To-Fabric printing?

Direct-to-fabric printing is gaining popularity for high-volume textile production, enabling on-demand, customized short runs. These printers offer ink flexibility, accommodating various fabric types like cotton and silk, though ink development focuses on faster turnaround by reducing pre- and post-processing. Compared to traditional methods, direct-to-fabric inkjet printing is a more sustainable option due to reduced water and chemical usage, and localized production.

What are the opportunities for large format providers regarding digital touch screens?

Digital touchscreens are becoming increasingly common, offering businesses opportunities to improve customer engagement and streamline operations. Nessan Cleary shares, while more expensive to implement than standard digital displays due to complex software and integration needs, touchscreens provide self-service options, multilingual support, and can reduce staffing costs in various settings like retail, transportation, and healthcare.