Designed to be Sustainable

.png?width=750)

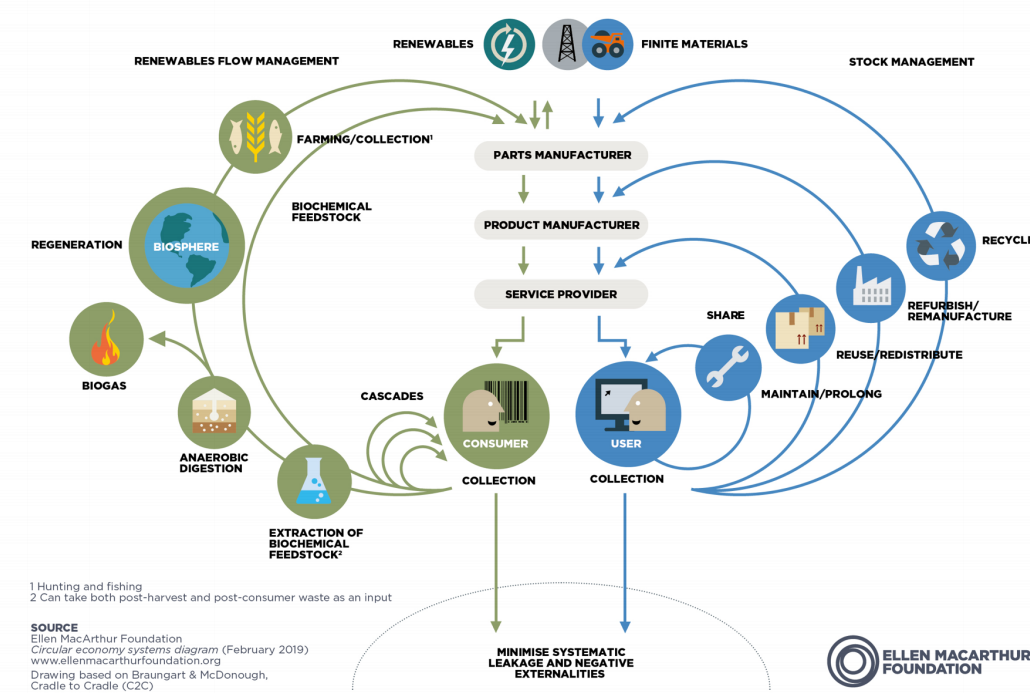

Laurel Brunner discuss 3 key objectives of having a Circular Economy, which includes designing products that eliminate waste and pollution; keeping products and materials in use for as long as possible; and supporting the regeneration of natural systems.

The ideas behind the Circular Economy aren’t much talked about in the grass roots printing business, but some of the principles are starting to creep into conversations. Three main objectives underpin a circular economy: design products to eliminate waste and pollution; keep products and materials in use for as long as possible; and support the regeneration of natural systems. It might be by accident but changes to how print media products are designed and produced, are bringing our industry into closer alignment with Circular Economy principles.

Print Service Providers (PSP) printing on paper substrates obviously contribute to recycling and regeneration. Printers produce most of their prints on paper and efforts to improve plastics recycling continue to gain ground. Digital printers often specialise in high value short run work produced on demand and in the required quantities. This is obviously less wasteful than the disposable print created on spec in case someone might want it. They also deliver high value print products that consumers want to keep. We treasure work such as photo albums and family posters especially if it is customised. Packaging printers are designing packaging to minimise materials and waste for brand owners who want greater environmental sustainability for their products. And across printing methods, printers are raising the quality of their output whilst simultaneously improving production efficiency to minimise waste.

Beyond digital printing companies are using other techniques to enhance value, such as innovative screen technologies that help optimise output quality on different substrates like kraft or uncoated papers. This takes digital colour management a step further, because it exploits screening technologies within the colour managed workflow. It’s also an approach companies can take to get older presses to perform better. We have spoken to a number of printers using new screening methods who say that the technology has also made possible very fast start-up and improved chromatic stability on long runs, as well as easier cleaning. It all makes for more sustainable production.

Innovation of this sort allows print buyers to use different printing methods with greater confidence. We’re seeing a clear migration away from gravure printing for instance. Sometimes it’s to offset or flexo, but for short run work it’s often to digital printing. Buyers can trust that there are PSPs around who will deliver, including digital printers. We are not yet seeing a clear preference for any particular digital printing technology, but inkjet is starting to gain ground in some packaging applications on the basis of improved quality and speed.

As brand owners start paying more attention to how print products are designed, PSPs are well placed to help. Technology that allows for control over run lengths, improved ink usage and recyclability all make a positive contribution to the sustainability conversation. And that’s a big positive for the Circular Economy of print.

This article was produced by the Verdigris Project, an industry initiative intended to raise awareness of print’s positive environmental impact. This weekly commentary helps printing companies keep up to date with environmental standards, and how environmentally friendly business management can help improve their bottom lines. Verdigris is supported by the following companies: Agfa Graphics, EFI, Fespa, Fujifilm, HP, Kodak, Miraclon, RicohSplash PR, Unity Publishing and Xeikon.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

The importance of ink for large format printers

Ink is crucial for large format inkjet printers, influencing substrate compatibility, productivity, and cost. Nessan Cleary discusses the three main types which include UV-curable ink, latex ink and eco-solvent ink. Each ink type has specific strengths and weaknesses, making printers choice dependent on budget and intended applications.

What are the benefits of Direct-To-Fabric printing?

Direct-to-fabric printing is gaining popularity for high-volume textile production, enabling on-demand, customized short runs. These printers offer ink flexibility, accommodating various fabric types like cotton and silk, though ink development focuses on faster turnaround by reducing pre- and post-processing. Compared to traditional methods, direct-to-fabric inkjet printing is a more sustainable option due to reduced water and chemical usage, and localized production.

What are the opportunities for large format providers regarding digital touch screens?

Digital touchscreens are becoming increasingly common, offering businesses opportunities to improve customer engagement and streamline operations. Nessan Cleary shares, while more expensive to implement than standard digital displays due to complex software and integration needs, touchscreens provide self-service options, multilingual support, and can reduce staffing costs in various settings like retail, transportation, and healthcare.