Digital Production Printing: The Unsung Hero of Print

Digital production printing, though less visible than large format printing, is a crucial force in the print industry. Sonja Angerer examines this segment, highlighting its focus on everyday print products, diverse technologies and streamlined production via inline finishing. While offering digital printing's benefits of flexibility and personalisation, it faces challenges like declining demand and web-to-print competition. Sonja Angerer sees future success depending on automation, niche specialisation and innovative customer solutions.

Digital printing is frequently equated with large-format applications. However, digital production printing is a distinct segment focused on the production of everyday printed items.

CAPTION: Ricoh offers a range of digital production printers for transactional and book printing. Photo: Ricoh

CAPTION: Ricoh offers a range of digital production printers for transactional and book printing. Photo: Ricoh

Digital Production Printing – technology

As with large format printing, four-colour inkjet is the most widely used technology in Digital Production Printing today. However, systems with laser or LED technology are also used, particularly for transaction printing and at in-house print shops. Konica Minolta recently launched the AccurioPrint C751i, a new series for in-house print shops in public authorities and associations, the education sector and healthcare. It works with the company's Simitri V polymerised toner technology.

Production printers with laser technology are often primarily intended for black and white printing in rather small volumes. However, manufacturers are also increasingly turning to inkjet for black and white printing, such as Ricoh's Pro VC40000 black and white inkjet roll-to-roll printing system, which has just been shown.

HP-ElectroInk is used in the large family of HP Indigo printers. Depending on the model, HP indigos are used for photos, packaging and commercial printing. The technology also allows printing with spot colours.

Landa Nanography was introduced in 2012 and combines elements of inkjet and laser technology with nano inks. The highly productive machines are mainly used for typical offset applications such as packaging and letterpress printing.

Like analogue printing, there are also two basic paper feeding options for digital print runs. Most digital production printing machines work with sheets, typically from A4 to B2, sometimes B1. One example is the current entry-level model for digital production printing, Canon varioPRESS iV7.

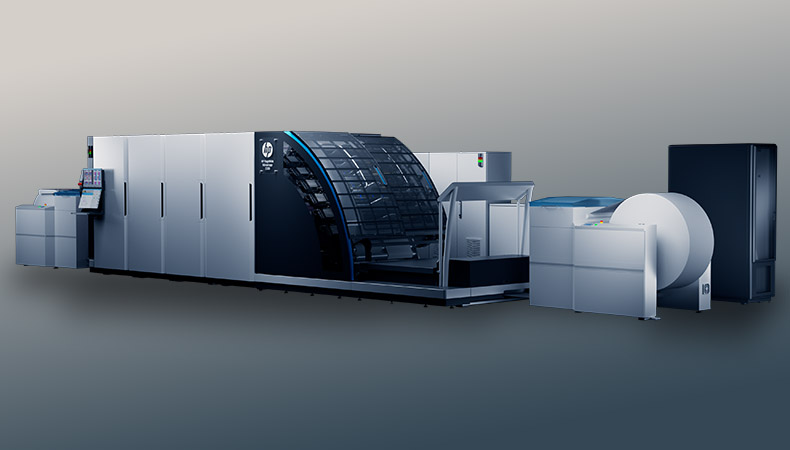

Web or continuous feed presses for Digital Production Printing, such as the HP PageWide Advantage 2200 models (video), are loaded with paper rolls up to approx. 60 cm wide.

Flatbed or roll-to-roll wide format printers are also sometimes used for jobs that can be classified as Digital Production Printing. This is particularly common in the field of photo and poster printing.

CAPTION: The HP PageWide Advantage 2200 web printer can print up to 244 meters per minute. Photo: HP

CAPTION: The HP PageWide Advantage 2200 web printer can print up to 244 meters per minute. Photo: HP

Digital Production Printing– areas of application

Digital Production Prints are used in three main segments:

-

Offset replacement: printing of magazines and books, mailings and brochures, general commercial printing in short runs, as well as label and packaging printing

-

Photo printing: prints, large formats, photo books, calendars, fine art

-

Individualisation / personalisation: personal mailings and marketing material, transactional printing.

Machinery for Digital Production Printing is often combined with inline finishing modules to create brochures or softcover books.

CAPTION: The AccurioPrint C751i printers from Konica Minolta are designed for in-house print shops and work with laser technology. Photo: Konica Minolta.

CAPTION: The AccurioPrint C751i printers from Konica Minolta are designed for in-house print shops and work with laser technology. Photo: Konica Minolta.

Advantages and disadvantages of Digital Production Printing

In direct comparison to analogue processes such as offset printing, Digital Production Printing offers all the advantages of going digital.

-

Fast and flexible: No need to create print templates.

-

Long run, short run or custom: Digital production printers can print short to medium runs with the same motif, with different versions and even as personalised one-offs.

-

Energy-efficient and environmentally friendly: Compared to analogue printing, Digital Production Printing consumes less electricity, water, chemicals and other raw materials. There is also less waste.

-

Less storage requirements: Since it is possible to reprint in small quantities as required, there is no longer any need to produce print material for stock.

For very long runs, however, Digital Production Printing still cannot compete with analogue processes such as offset or gravure printing. This is because ink and paper for digital printing are usually much more expensive. Another disadvantage is that the technology in digital printing is still advancing much faster than in analogue processes. This means that a Digital Production Printer becomes obsolete much faster than an analogue model.

Although the individual Digital Production Printer is probably much cheaper than a high-quality offset printing line, this usually results in an increased need for investment over the decades.

CAPTION: The Canon varioPRESS iV7 model is intended for beginners in Digital Production Printing and processes sheets up to B2 format. Photo: Canon.

CAPTION: The Canon varioPRESS iV7 model is intended for beginners in Digital Production Printing and processes sheets up to B2 format. Photo: Canon.

Future prospects of Digital Production Printing

Digital production printing is expected to maintain its position in the market, with the rising demand for individualised and personalised items leading to further adoption and a corresponding decline in offset printing.

However, Digital Production Printing, like analogue processes, has been affected by the disappearance of entire segments within the printing industry. There is hardly any demand for simple commercial jobs such as business cards or stationery. The remaining orders are usually produced by highly automated Web2Print printers at extremely low prices.

Personalised mailings and transactional prints, such as credit card statements, have already been largely replaced by electronic communication. Many customers now even prefer magazines, brochures and leaflets as PDFs. There is currently increased demand in some segments of book printing. It remains to be seen whether this development will continue.

For Digital Production Printing, this means that companies must rely on automation and digitisation for standard orders more than ever. At the same time, it may be wise to concentrate on niches such as package inserts and to offer customers innovative products for their requirements as "problem solvers".

Discover the latest innovations in digital printing at FESPA Global Print Expo 2025, Europe's leading print and signage exhibition taking place from 6 - 9 May at Messe Berlin, Germany. It will showcase the most innovative products, visionary concepts, and latest developments in the future of print. Register to visit here and use promo code FESJ505 and pay only 25 euros for your entrance ticket.

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

.png?width=550)

What qualities should visionaries in print have? With Folker Stachetzki from Brother

We speak to Folker Stachetzki, Head of Marketing at Brother about visionaries in print.

Bolstering personalisation by combining print and digital technology

Using printed material in combination with digital technologies offers more opportunities to those offering personalisation to customers. Rob Fletcher shares some recent examples of the print and digital working together to enhance the impact of personalised pieces.

European Sign Expo to highlight developments shaping the future of signage and visual communications

European Sign Expo 2025 (6 – 9 May, Messe Berlin, Germany) is weeks away and a host of leading exhibitors are all set to welcome Visionaries from across the signage and visual communications industries to their stands.