Durst names first beta site for new Tau 330 RSC press

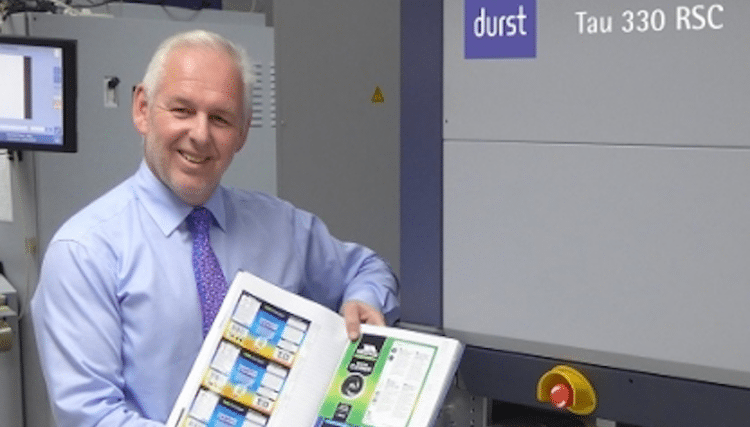

The Label Makers will be the first beta site customer for Durst’s new digital, high-speed, eight-colour Tau 330 RSC label press.

Testing for the device will begin in October at The Label Makers’ premises in Bradford, UK. This new inkjet label press, as well as Durst’s new Web2Print workflow, will be officially launched later this month.

The Label Makers managing director David Webster commented: "Durst has been an incredibly supportive partner with fantastic technology as we continue to develop our business into new and developing markets. As a pioneer, we’re constantly wanting to keep ahead of the curve and becoming the first customer to install the Tau 330 RSC is another huge step forward for us."

The Durst’s Tau 330 press can print at speeds of up to 78m/min (linear) at resolutions of up to 1,200dpi. The device has eight colour stations – CMYK plus white, orange, violet and green – and its maximum production capacity is 1.485sqm/hr.

According to Durst, newly designed high-pigmented inks deliver print quality comparable to flexo with close to 98% Pantone colour gamut coverage.

Helmuth Munter, segment manager for label and package printing at Durst, continued: "We’ve worked in true partnership with David and his team for a long while. We are proud and excited to announce that The Label Makers will be the first company to benefit from this new and game-changing technology."

"The system, which boasts unmatched printing speed and printing quality, is already creating huge interest prior to its official launch at Labelexpo. It’s a perfect solution for label converters that are looking for an industrial scale digital press solution."

Tau 330 RSC is available as stand-alone version or can be combined with in-line digital laser die cutting LFS 330.

Webster concluded: "The increases in speed and quality makes the Durst Tau 330 RSC as competitive as most flexo presses. While it’s not the be-all and end-all of print, I definitely see the future of label production as inkjet. We’re confident that this new press will once again open up many more doors as we continue to expand."

The Tau 330 RSC forms part of a major investment drive at The Label Makers worth around £2m. In the next two months it will also take delivery of a new MPS flexo press while it is upgrading one of its three ABG Digicon label converters to run at speeds of up to 150m/min

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

The importance of ink for large format printers

Ink is crucial for large format inkjet printers, influencing substrate compatibility, productivity, and cost. Nessan Cleary discusses the three main types which include UV-curable ink, latex ink and eco-solvent ink. Each ink type has specific strengths and weaknesses, making printers choice dependent on budget and intended applications.

What are the benefits of Direct-To-Fabric printing?

Direct-to-fabric printing is gaining popularity for high-volume textile production, enabling on-demand, customized short runs. These printers offer ink flexibility, accommodating various fabric types like cotton and silk, though ink development focuses on faster turnaround by reducing pre- and post-processing. Compared to traditional methods, direct-to-fabric inkjet printing is a more sustainable option due to reduced water and chemical usage, and localized production.

What are the opportunities for large format providers regarding digital touch screens?

Digital touchscreens are becoming increasingly common, offering businesses opportunities to improve customer engagement and streamline operations. Nessan Cleary shares, while more expensive to implement than standard digital displays due to complex software and integration needs, touchscreens provide self-service options, multilingual support, and can reduce staffing costs in various settings like retail, transportation, and healthcare.