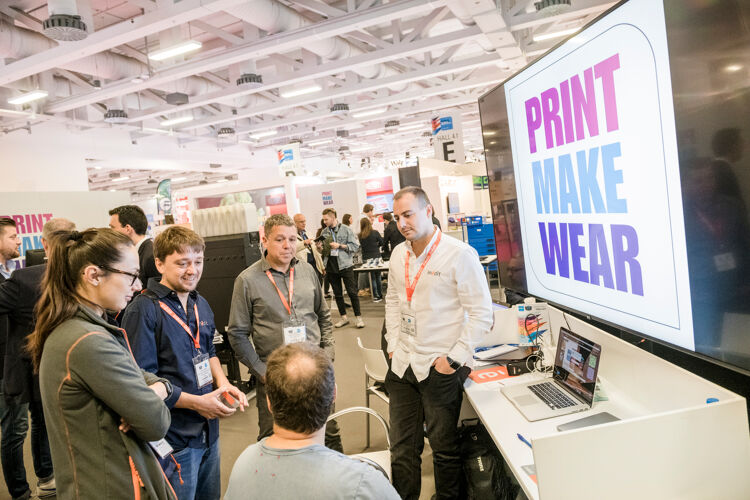

Exhibitor line-up and debate sessions confirmed for print make wear 2019

FESPA has revealed the line-up of technologies and exhibitors for its Print Make Wear microfactory feature, which will take place at FESPA Global Print Expo 2019 from 14 to 17 May at Messe Munich, Germany.

The products highlighted within Print Make Wear will be provided by 19 exhibitors and will be presented within two separate tours, one focused on roll-to-roll technologies and the second on garment decoration. The technology demonstrations will be supported by a programme of talks and catwalks to enhance the visitor experience.

.jpg?lang=en-GB)

Roll-to-roll technologies

The roll-to-roll tour will be split into two separate workflows, one on pigment printing and the other on dye-sublimation printing.

The pigment printing workflow route will include:

- Design software from Adobe Textile Designer and EFI Fiery DesignPro with Adobe CS

- Fabrics provided by Premier Textiles

- EFI Optitex pattern design and marker making

- Pre-press production files from EFI Fiery

- RIP and pigment printing inks from Mimaki

- A Klieverik dryer

- Cutting solution from Gemini

The dye-sublimation printing workflow will include:

- Adobe Textile Designer design software

- Fabrics provided by Premier Textiles

- A selection of transfer paper from CANAPA

- Gemini will supply its product design and decoration software, Gemini CAD pre-press production files and a cutting solution

- RIP and dye-sublimation inks from HP

- Klieverik heat transfer machine

- Grafco colour separation technology and inks for the Vastex manual screen printing press

- FairTrade fabric garments provided by Neutral

- A Chiossi e Cavazzuti dryer

- Folding and packaging system by Thermotron

- Easiway screen reclamation

- An MHM automatic screen printing press

- Magna Colours’ inks for the automatic screen printing press

- A manual screen printing carousel from Vastex and a Vastex Little Red dryer

- A Tesoma tunner dryer will be used for the automatic screen printing

- A Stahls heat press will be used for hot foil decoration

‘Fireside Chats’

- The Micro Factory and Customisation, moderated by Jenny Holloway from Fashion Capital and including speakers from EFI, Mimaki, HP and Gemini.

- Sustainability and Efficient Manufacturing, hosted by Elissa Decker of Moss Inc., and Lars Bech, CEO of Neutral, featuring speakers from Premier Textiles and Magna Colours.

- Automating the production workflow, comprising speakers from Gemini, EFI and HP.

- Designing for digital print and colour management, to include speakers from Adobe, AVA and EFI

The sessions will take place at 13:00h within Print Make Wear (Hall B6, Stand A80). In addition the designs by illustrator Jasper Goodall printed within the feature will be displayed on the catwalk three times a day Tuesday 14 to Thursday 16 May and twice on the Friday 17 May.

.jpg?lang=en-GB)

For visitors looking for more detailed information on the technologies used, daily expert-guided tours can be booked in advance here.

The full schedule for the Print Make Wear tours, catwalks and fireside chats can be viewed here

Sustainability will be a key theme at FESPA 2019 this year and FESPA will champion a number of initiatives within the Print Make Wear feature to be more environmentally responsible. The garments used for the direct-to-garment textiles will be provided by Neutral, a market-leading producer of sustainable apparel and accessories to the B2B market, which use FairTrade cotton and have been awarded the EU Ecolabel for meeting high environmental standards. Water-based inks from Magna Colour will also be used on the automatic screen printing press.

Graeme Richardson-Locke, Technical Support Manager at FESPA, comments: “Over the years FESPA’s commitment to textile printing and garment decoration has developed and we’ve considerably expanded our visitor proposition in this area in line with growing industry demand. For Print Make Wear 2019 we have put together a programme that represents the different facets of the garment manufacturing community and are confident that this will help garment manufacturers understand the range of technologies at their disposal.”

For more information on Print Make Wear and FESPA Global Print Expo 2019 visit here. Use code FESM911 for free entry when registering before midnight on Monday 13 May 2019.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

The importance of ink for large format printers

Ink is crucial for large format inkjet printers, influencing substrate compatibility, productivity, and cost. Nessan Cleary discusses the three main types which include UV-curable ink, latex ink and eco-solvent ink. Each ink type has specific strengths and weaknesses, making printers choice dependent on budget and intended applications.

What are the benefits of Direct-To-Fabric printing?

Direct-to-fabric printing is gaining popularity for high-volume textile production, enabling on-demand, customized short runs. These printers offer ink flexibility, accommodating various fabric types like cotton and silk, though ink development focuses on faster turnaround by reducing pre- and post-processing. Compared to traditional methods, direct-to-fabric inkjet printing is a more sustainable option due to reduced water and chemical usage, and localized production.

What are the opportunities for large format providers regarding digital touch screens?

Digital touchscreens are becoming increasingly common, offering businesses opportunities to improve customer engagement and streamline operations. Nessan Cleary shares, while more expensive to implement than standard digital displays due to complex software and integration needs, touchscreens provide self-service options, multilingual support, and can reduce staffing costs in various settings like retail, transportation, and healthcare.