Wide Format Digital Printing and the Environment

.png?width=750)

Laurel Brunner discusses how with direct digital output there are no no interim processes between the data and the physical prints, which saves production consumables and energy.

One of the great advantages of direct digital printing is that it delivers solid economic and environmental improvements over conventional printing methods. With direct digital production, costs are the same per copy for one print as they are for a million.

Before Xeikon and Indigo introduced their digital colour presses in 1993, print required complex prepress to produce a printing forme for the press. Most printers still imaged to film which was then placed in a printing down frame to expose a printing plate. Gradually, and surprisingly slowly, developers worked out how to image direct-to-plate, without the interim film stage. This saved time and energy and improved output quality, because it produced first generation dots.

When digital printing first emerged, it was widely ridiculed by the printing and publishing establishment. They did not believe that digital imaging direct to substrate could ever compete on quality with conventional processes, such as offset and screen printing. It took a while, but today it is often hard to tell the difference between digital and other production methods. Printing projects that cannot be produced using digital techniques are ever more rare, and the positive impact on the environment has been substantial.

The beginning of the end

None of this was particularly good news for the consumables suppliers. It meant that there was no film to buy, image and dispose of, and nor were there film and plate processing chemicals to manage. Computer-to-plate (CtP) production was probably the first serious jump in prepress towards improved sustainability in the graphics industry. However this leap was not made because printers and their customers cared about the environment. Increased capacity in the market and tumbling prepress costs forced the industry to look at new ways to compete and reduce production costs. Money was the driver of prepress and workflow automation, much as it is today. But environmental impact mitigation was an unexpected and positive consequence.

Caption: Sonora XP printing plates are imaged on press so they do not need any offline processing chemistry. Water, chemicals, energy, time and costs are saved, reducing the environmental impact of the print.

Digital colour printing technology made short run printing viable, leading to waste reductions and market consolidation. The introduction of processless printing plates by Kodak, Agfa and Fujifilm allowed plates to be imaged on press, reducing the need for offline chemistry and processing steps. This has been another big plus for the environment. Advances with plate coatings such as Kodak’s Sonora have given us robust processless plates that work well for thousands of impressions, even with aggressive inks. This may not matter for wide format digital printing, but it’s an important driver of advances in the graphics business. And if your wild format project needs to be printed on an offset press, you can trust that there are environmentally friendly options.

Sustainability and sustainability

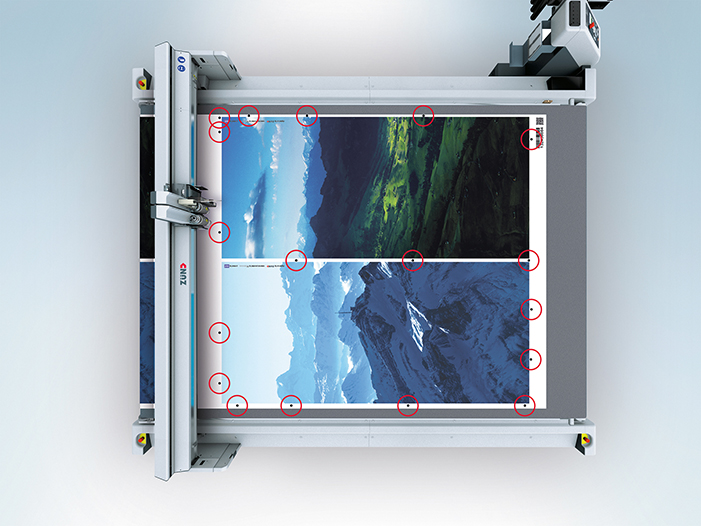

Prepress got smarter thanks to technologies such as the PostScript page description language and its descendent PDF, as well as increasingly powerful hardware platforms. Technology has helped many companies to survive and created new opportunities in graphics for others. Going direct to plate and press and then outputting direct to wide format digital presses was inevitably just a matter of development. Innovations in hardware, printheads, inks and substrates combined to support new wide format digital printing applications, such as signage and packaging and more recently, textiles. Software advances continue to ensure that all data, from concept to the final cutting of the product is planned and efficient. Digital data processing ensures the mechanical precision of hardware such as Zünd’s G3 cutting system for textiles.

Variable data and the market of one

Sending data direct to press and finishing at high speeds gives digital colour printing another serious advantage over analogue equivalents. The data that appears on the page, from A4 to A0 and above is not bound to that page; it is not fixed in any way. Every piece of output can be different. In just the same way as one might print a whole series of different documents on a desktop printer throughout the day, that same series can be printed direct to press but at phenomenal speed and quality.

Print produced in this way can be specific to the recipient adding value to the piece and also to the project, since print is more likely to get a response if it is bespoke. As a platform static print cannot compete with online digital platforms, but variable data digital colour print can. Print also has a one time carbon footprint, so once a wedding invitation say, is produced and delivered, it requires no resources to use. This is not the case with an online equivalent viewed on a computer screen, delivered via the internet and stored in a data farm, mirrored in the cloud and possibly multiple times. The associated energy emissions are colossal, and the carbon footprint of that electronic wedding invitation eye watering.

Today digital colour printing technologies are available for a dizzying array of narrow and wide format applications. They work on an equally dizzying array of substrates, from thin films through to thermoforming plastics, and they serve a chaos of new applications. The explosion in short run on demand print applications has decimated large parts of the traditional graphics industry, and the waste associated with it. Technology has driven waste levels down and allowed us to print close to the point of use which also reduces emissions associated with transportation. But they have also created new waste related headaches.

Waste management

Handling electronic environmental footprints and waste are off topic for this article however they are vital considerations for anyone involved in the media business: creator, producer and everyone in between. Waste management in wide format digital colour production is a serious concern because a lot of output is only used for one off projects such as signage. But here too investment choices can make a difference. Working with output devices based on environmentally friendly technologies such as UV curing and water based inks as is the case with HP Latex make a difference. But working with technologies that image recycled materials or materials that decompose in landfill also helps. The most powerful contributor to waste management however is data management, particularly colour data management, that ensures a print job is perfect when it is proofed and printed. Effective colour management guarantees softproof accuracy for predictable output. Ensuring that all links in the supply chain operate in a colour managed environment helps minimise waste and negative environmental impacts.

Recycling

Caption: Zünd combines a cutting table with an Over Cutter Camera that captures registration marks so that powerful algorithms can adjust cutting to compensate for distortions on the cutting bed.

Perhaps the greatest environmental challenge facing the graphics industry is to manage recycling processes more effectively. This industry, as with others, must take bigger steps to encourage the circular economy whereby waste can provide the basis for raw materials for other processes. We have some great examples, such as using waste paper to make new papers, and sending used aluminium printing plates to be melted down for other purposes. But we need to do much more, for instance in sorting materials and in improving processing of printed papers. Today’s waste prints are produced using an array of technologies, and yet paper and pulp plants struggle to process them efficiency. Rather than investing in new research and methods the inclination is to stop the clock, and this undermines the graphics industry’s environmental credentials. This must change.

New materials

Fortunately there are plenty of people around the world aware of the need to act, from carbon offsetting projects through to substrate innovations. Plastics can be made from vegetable materials and print service providers work with customers to develop bespoke substrates that work for a given application. Cactus Imaging in Australia for instance has co-developed SmartSkin, a recyclable high density polyethylene for billboards, working with Australian Ethical, an investment fund.

.png?lang=en-GB)

Caption:SmartSkin was co-developed by Cactus Imaging and its client Australian Ethical. It’s an alternative to PVC which is the preferred choice for billboards in Australia, where the climate is not kind to the paper variety.

The environment and its protection is becoming top priority for most industries. In the graphics sector interest has been bubbling away in isolated pockets, but greater commitment to impact mitigation is becoming urgent. Creators, end users and print buyers show their power to make this happen when they opt for environmentally sustainable production for wild format projects. The time is now.

Source information: The Wild Format guides are intended to expand awareness and understanding of the craziness that can be created on wide format digital printing devices, from floors to lampshades and everything in between. These guides are made possible by Digital Dots with generous support from HP and Zünd.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

The Rise of B2B in Print-On-Demand: Mastering Personalisation to Drive Growth

Rusty Pepper highlights the B2B shift in Print-On-Demand, focusing on personalisation's role in driving growth. He discusses market differences between Europe and the U.S., challenges in global scaling, and strategies for successful implementation. Experts will share insights at FESPA 2025, covering automation, fulfilment, and market trends.

Navigating the Evolving Landscape of Fashion, Print and Sustainability

In this podcast, Debbie McKeegan and April Holyome – head of Product at the luxury Italian brand 16Arlington discuss the evolving landscape of fashion at the Epson Textile Academy.

.jpg?width=550)

Awarding Talent: Joanne O’Rourke Wins the Epson Eco Stories Textile Challenge and Trip to FESPA 2025

Joanne O'Rourke won the Epson Eco Stories Textile Challenge, receiving an Epson SureColor SC-F100 printer and a trip to FESPA 2025 in May. The award highlights the importance of supporting emerging designers for a sustainable print industry. These "digital natives" drive innovation, sustainability, and technological advancement, crucial for the sector's future.

The importance of Personalisation in Direct Mail - The Power of Print

Jeroen van Druenen, CCO of Jubels discusses how personalised direct mail, especially print, boosts engagement and ROI by tailoring content to individual recipients. Using variable data printing (VDP), marketers create unique designs and offers, enhancing relevance and fostering stronger customer relationships. Physical mail's tangibility and lasting impact further amplify personalisation's effectiveness.