Heidelberg introduces new rotary die-cutter

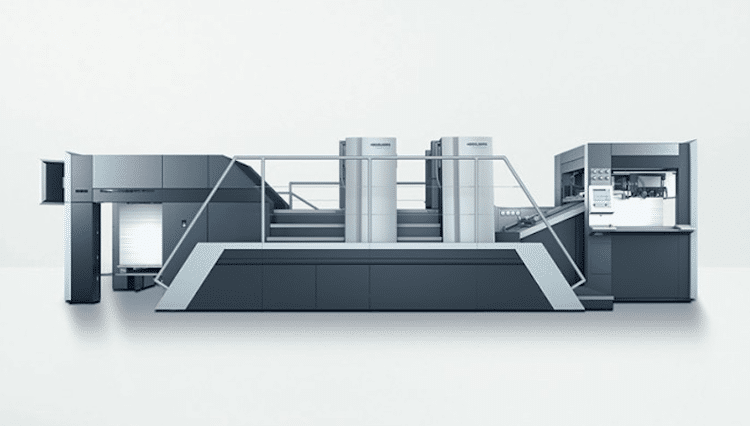

Heidelberg has launched its Speedmaster XL 106-DD rotary die-cutter for the in-mould label (IML) market.

The in-mould label market is continuously growing globally at around 4.3% (Awa Global Inmould Study 2017), and more than two thirds of the worldwide production is required for food packaging. Heidelberger is now offering an enhanced rotary die-cutter based on the XL technology, in addition to food-safe, highly efficient print production.

The Speedmaster XL 106-DD rotary die-cutter unites two key production steps in a single machine. The first unit places the injection hole in the label for the subsequent production process by means of a die on a magnetic cylinder with maximum precision. Up to now, this was a separate step that consequently extended the production time of the respective job.

The cut out material is safely and reliably removed by means of an extraction system. The second unit of the XL 106-DD subsequently cuts out the contour of the label from the sheet.

This combination of the two production steps in a single pass means a doubling of the die-cutting throughput, while makeready times and costs for die cutting tools can be reduced to half.

The XL 106-DD can process foils and papers at up to 10,000sph, which Heidelberg says is double the speed of a flatbed die-cutter, and takes materials ranging in thickness from between 0.05mm and 0.3mm.

Apart from in-mould labels, the XL 106-DD can also cut plastic or paper packaging elements, such as POS items which, due to their design, need a ‘window’ or hole for mounting in the shelf or for attaching to the product.

“A lot of customers are asking for this solution, who already have flatbed die-cutters but want the possibility to do hole punching and now we have the solution that they can completely change to rotary die-cutting,” commented Heidelberg product manager Philipp Doley to Printweek.

“On a flatbed die-cutter the cutting process for the sheet has to stop completely and speed up 100% afterwards, so you always have a hard stop and a hard run. On rotary, the sheet is always moving."

“The market is changing so if you have the possibility to cut and blend holes you can also speak about different kinds of holes, not only small injections but also the possibility to cut a window and extract the window in the label. So maybe this creates a new kind of product,” Doyle concluded.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

.png?width=550)

My Personalisation Experience

Richard Askam, a pioneer in Personalisation, transitioned from the drinks industry to creating iconic campaigns like Coca-Cola's "Share a Coke." His speaking career, includes leading a TEDx talk, becoming an ambassador for FESPA . In the past, he has led the conference sessions for the Personalisation Experience" conference, and will return this year to speak in a panel discussion.

The Rise of B2B in Print-On-Demand: Mastering Personalisation to Drive Growth

Rusty Pepper highlights the B2B shift in Print-On-Demand, focusing on personalisation's role in driving growth. He discusses market differences between Europe and the U.S., challenges in global scaling, and strategies for successful implementation. Experts will share insights at FESPA 2025, covering automation, fulfilment, and market trends.

Navigating the Evolving Landscape of Fashion, Print and Sustainability

In this podcast, Debbie McKeegan and April Holyome – head of Product at the luxury Italian brand 16Arlington discuss the evolving landscape of fashion at the Epson Textile Academy.

.jpg?width=550)

Awarding Talent: Joanne O’Rourke Wins the Epson Eco Stories Textile Challenge and Trip to FESPA 2025

Joanne O'Rourke won the Epson Eco Stories Textile Challenge, receiving an Epson SureColor SC-F100 printer and a trip to FESPA 2025 in May. The award highlights the importance of supporting emerging designers for a sustainable print industry. These "digital natives" drive innovation, sustainability, and technological advancement, crucial for the sector's future.