HP and EarthShift to examine the impacts of 3D printing

Life cycle assessment and sustainability return on investment studies provide management insights into environmental, social, economic effect.

EarthShift Global LLC and HP will outline the environmental, social, and economic impacts of advanced printing technologies, including 3D printing, at this week’s International Society for Industrial Ecology/International Symposium on Sustainable Systems and Technology (ISIE/ISSST) conference in Chicago.

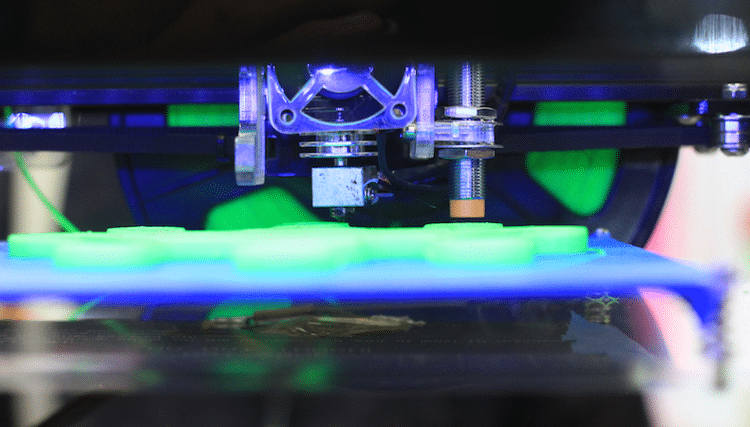

Representatives of the two companies will report on third-party-reviewed Life Cycle Assessment (LCA) studies of HP’s Multi Jet Fusion 3D printing technology and HP Indigo 20000 Digital Press printing system. The environmental impacts of both systems are assessed across multiple scenarios and compared with traditional technologies.

In addition, EarthShift Global founder and CEO Lise Laurin will discuss a broader Sustainable Return on Investment (S-ROI) study of 3D printing of plastics, revealing previously unavailable insights into the potential magnitude of externalities—social, economic, and environmental risks and opportunities associated with the increasingly popular technology.

S-ROI presents stakeholder-oriented information in a monetized model, allowing it to be used alongside traditional financial metrics for triple-bottom-line decision-making at HP and other companies. “In its product development process, HP has shown a commitment to helping its customers, and customers’ customers, perform better on environmental and social metrics,” said Laurin.

“By the time the Indigo study had been peer-reviewed, HP had already begun implementing some of the recommendations. These efforts will have worldwide impact across thousands of product lines, and exemplify private-sector leadership in sustainability. We’re proud to collaborate with them.”

Slated for presentation at ISIE/ISSST are:

- A Comparative Life Cycle Assessment of HP’s Multi Jet Fusion Additive (3D Printing) Manufacturing with Injection Molding—Using direct comparisons of actual automotive parts, this session looks at the environmental benefits of additive manufacturing, including the ability to use less material without compromising structural integrity and extend product lifetimes due to increased availability of replacement parts.

- Life Cycle Assessment Comparison of Flexible Packaging Printed Using Three Different Methods for Short-Run Jobs—This session models the impacts of producing flexible packaging for a consumer product using HP Indigo 20000 digital printers and traditional flexographic and gravure techniques, including direct costs, energy consumption, manufacture and disposal of consumables, and waste generated during production. A white paper on the study is available for download.

- Assessing the Sustainability of 3D Printing of Plastics—This study uses an S-ROI approach to evaluate environmental, social, and economic risks and opportunities related to broad uptake of 3D printing, including the availability of customized, inexpensive prostheses, encouragement of entrepreneurship in developing countries, design piracy, and the manufacture of weapons.

The EarthShift Global and HP representatives will be available for discussion during the ISIE/ISSST conference, which runs from June 25-29 at the University of Illinois at Chicago Forum, 725 West Roosevelt Road, Chicago, IL.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

The Rise of B2B in Print-On-Demand: Mastering Personalisation to Drive Growth

Rusty Pepper highlights the B2B shift in Print-On-Demand, focusing on personalisation's role in driving growth. He discusses market differences between Europe and the U.S., challenges in global scaling, and strategies for successful implementation. Experts will share insights at FESPA 2025, covering automation, fulfilment, and market trends.

Navigating the Evolving Landscape of Fashion, Print and Sustainability

In this podcast, Debbie McKeegan and April Holyome – head of Product at the luxury Italian brand 16Arlington discuss the evolving landscape of fashion at the Epson Textile Academy.

.jpg?width=550)

Awarding Talent: Joanne O’Rourke Wins the Epson Eco Stories Textile Challenge and Trip to FESPA 2025

Joanne O'Rourke won the Epson Eco Stories Textile Challenge, receiving an Epson SureColor SC-F100 printer and a trip to FESPA 2025 in May. The award highlights the importance of supporting emerging designers for a sustainable print industry. These "digital natives" drive innovation, sustainability, and technological advancement, crucial for the sector's future.

The importance of Personalisation in Direct Mail - The Power of Print

Jeroen van Druenen, CCO of Jubels discusses how personalised direct mail, especially print, boosts engagement and ROI by tailoring content to individual recipients. Using variable data printing (VDP), marketers create unique designs and offers, enhancing relevance and fostering stronger customer relationships. Physical mail's tangibility and lasting impact further amplify personalisation's effectiveness.