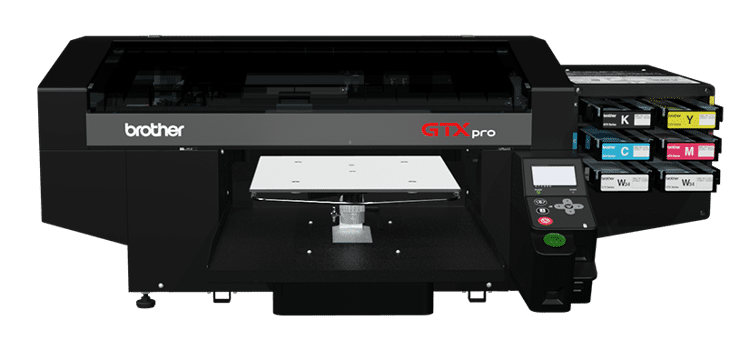

Brother releases GTXpro, the latest direct to garment printer

Brother At Your Side has launched the Brother GTXpro, their latest direct to garment printer which is currently available at their certified dealers.

Brother experienced success after launching the mass production machine GTXpro BULK a few months ago. The GTXpro provides the benefits of an operator friendly high-end direct-to-garment printer accompanied with leading technology from Brother.

GTXpro Features:

Newly Designed Industrial White Print Head

- Newly developed white print head technology with inside ink circulation, which results in using less white ink for cleaning.

High-Speed Print Mode

- The new design of the white print head features more nozzles compared to previous

models. This addition results in a 10% faster printing with special “fast mode” print settings.

Optimized Maintenance Process:

- Automatic cleaning processes significantly increases productivity.

Environmentally friendly

- OekoTex Passport and GOTS 5.0 certified Innobella Textile Inks

Operator friendly

- Installation and training by an authorized Brother DTG technician

- Additional Print Height Sensor: The new sensor technology detects if the platen is too low in order to reduce ink mist and ensures high print quality.

- Print Reservation Function for higher productivity

Flexibility

- Easy printing on a wide variety of textiles such as trousers, shoes, caps and much more.

- Printing on various materials is possible, from cotton to silk or polyester - all featuring the same ink.

- Compact industrial design and size suitable for all kind of production environment.

- Easy to move and add to any production – for a flexible process modulation of your production.

- All additional products from the GTX can be used with the GTXpro.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

The importance of ink for large format printers

Ink is crucial for large format inkjet printers, influencing substrate compatibility, productivity, and cost. Nessan Cleary discusses the three main types which include UV-curable ink, latex ink and eco-solvent ink. Each ink type has specific strengths and weaknesses, making printers choice dependent on budget and intended applications.

What are the benefits of Direct-To-Fabric printing?

Direct-to-fabric printing is gaining popularity for high-volume textile production, enabling on-demand, customized short runs. These printers offer ink flexibility, accommodating various fabric types like cotton and silk, though ink development focuses on faster turnaround by reducing pre- and post-processing. Compared to traditional methods, direct-to-fabric inkjet printing is a more sustainable option due to reduced water and chemical usage, and localized production.

What are the opportunities for large format providers regarding digital touch screens?

Digital touchscreens are becoming increasingly common, offering businesses opportunities to improve customer engagement and streamline operations. Nessan Cleary shares, while more expensive to implement than standard digital displays due to complex software and integration needs, touchscreens provide self-service options, multilingual support, and can reduce staffing costs in various settings like retail, transportation, and healthcare.