James Hamilton achieves Screen world first

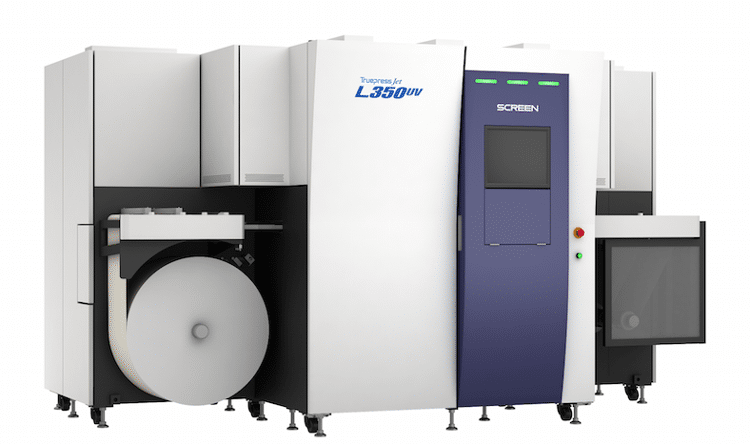

The James Hamilton Group has become the first company in the world to install a Screen Truepress Jet L350UV+ press for its labels division.

Based in Lurgan, Northern Ireland, James Hamilton Group will use the UV inkjet press to produce food, beverage and chemical product packaging labels.

The family-run company wanted a digital solution to complement its existing flexo label lines in order to respond to increasing requirements for shorter run lengths. Following a near nine-month process of due diligence travelling throughout Europe to visit different manufacturers, it chose the Screen Truepress Jet L350UV+ press for its combination of efficiency and quality with a top speed of 60m/min.

"The business needed more capacity and we knew right at the start we were looking for a digital solution to complement our existing flexo press lines in order to respond to the ever-increasing requirements for shorter run lengths and increased SKUs," commented James Hamilton group managing director Keith Hamilton.

"The Screen Truepress Jet L350UV+ was a clear choice for us because it ticked so many boxes; Screen’s UV inkjet technology delivers tried and tested quality, it has an excellent reputation for reliability and with the 60m/min speed, it’s becoming a real rival to flexo production."

The Jet L350UV+ features proprietary screening technology with one of the smallest droplet technologies commercially available. Colour gradations, image and text detail are achieved by the system’s high-resolution screening and ink spread compensation software functionality.

It has a wide-gamut proprietary inkset and Vivid Color Mode printing, while a stable transport mechanism controls paper feeding to prevent meandering and maintain optimal transfer conditions for registration accuracy.

“Our customers expect premium quality print," said general manager David Hedley. "With the new Screen press we’ll be able to offer something different in the extended orange color gamut, which in turn will meet their stringent quality requirements, in addition to providing a faster service. I believe our customers will be very happy with our choice."

Named for its founder when established in the 1920s, the James Hamilton Group began as a supplier of wrapping papers and twine. Today, overseen by James Hamilton’s great grandson Keith, the group is made up of divisions including label solutions, print, packaging, and office supplies.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Streamlining personalisation with tech: Insights from the SmartHub Conference 2025 speakers

Personalisation Experience 2025 (6 – 9 May 2025, Messe Berlin, Germany) is running its inaugural SmartHub Conference from 6 – 8 May 2025.

Special Effects in DTF: How Neon Inks Are Making Apparel Pop

Neon fluorescent inks are the latest innovation in DTF printing, offering vibrant, eye-catching effects under both daylight and UV light, giving apparel decorators a competitive edge. Testing shows good wash durability, though market perception of added value is still developing. With increasing adoption and ongoing technological advancements, neon represents a significant upgrade for creative customisation.

Unlocking Growth Opportunities in the Printed Personalised Apparel Industry

The printed personalised apparel industry is booming, projected to reach $10.1 billion by 2030. Driven by consumer desire for self-expression and branding needs, technological advancements like DTG/DTF and e-commerce integration are key. Sustainability, eco-friendly materials, and on-demand printing are crucial growth drivers. Businesses leveraging these trends, including AI and social media, have significant commercial potential.

Personalisation: From mass production to print-on-demand

Technological advancements are driving the growing trend of personalisation, fueled by consumer demand for unique products. From packaging campaigns like Share-a-Coke to customised apparel by Nike and Adidas, and AI-powered tools, the shift from mass production to print-on-demand is evident. The SmartHub Conference at the Personalisation Experience from 6 - 8 May will explore these opportunities and challenges for businesses.