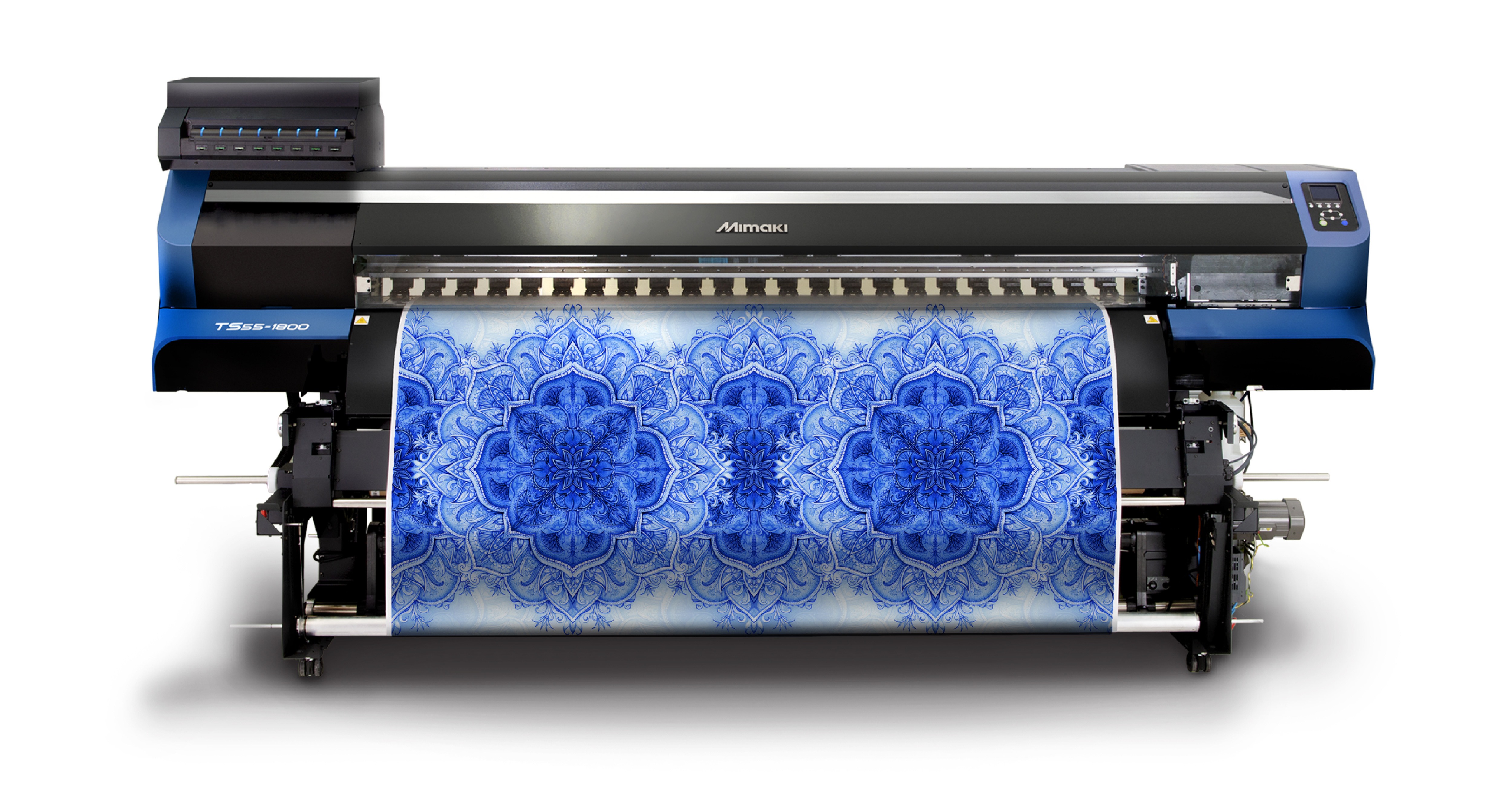

Mimaki targets textiles with TS55-1800

.jpg?width=750)

Rob Fletcher speaks to Mimaki about the TS55-1800, a breakthrough digital textile printer that will surely cause a stir in the market.

Mimaki has expanded its portfolio of digital print solutions with the launch of the new TS55-1800, a machine designed to address growing demand for work in the printed textiles market.

The digital heat transfer sublimation printer pledges to bring “high-end features” to entry-level and mid-level markets. Key features include one-pass printing at a high-resolution and ink-density, unattended printing with the new Mini Jumbo Roll, and Mimaki’s Nozzle Check and Recovery System for continuous operation.

Mimaki said the TS55-1800 can print at speeds of up to 140sq m/hr and at a resolution of 480 x 600dpi. In addition, the manufacturer said that the Mimaki Advanced Pass Systems will boost the quality of two-pass prints by eliminating banding.

Speaking to FESPA.com about the new printer, Bert Benckhuysen, senior product manager at Mimaki, said the main reasons behind developing the product were to deliver a solution that is of “higher quality, more productive, and more price-competitive” that offers users “higher profitability”.

“We believe the TS55-1800 ticks all these boxes; it’s a robust, productive dye sublimation printer that produces high quality results and offers our customers an increased price-performance ratio,” Benckhuysen said.

“With the new (r)evolutionary Mimaki TS55-1800, we are also bringing features that are normally only found in high-end textile printers to the entry and mid-level market.

“For example, we’ve added high-speed one-pass and two-pass printing at a high resolution and with high ink density. This means that while our competition has to reduce speed to maintain strong colours, we can deliver with one-pass at 140sq m/hr.

“Furthermore, we introduce our new Mini Jumbo Roll unit, which will enable our customers to continuously print up to 2,500 linear meters of heat transfer paper with this printer, saving on paper running cost. Additionally, to even go lower in running costs, the TS55 can be equipped with a 10kg ink supply system.”

In terms of the type of companies that should look to invest in the new machine, Benckhuysen said Mimaki designed the product with all customers in mind and suggested that the TS55-1800 would fit into all types of textile print business.

“Textile production companies, no matter how big or small, can definitely benefit from this printer,” he said. “We want to help them realise higher profit and grow their business with this amazing, market-stirring printer.”

Benckhuysen added in a statement: “The TS55-1800 is a breakthrough digital textile printer, that will surely cause a stir in the market. It has been designed from the ground up to deliver high quality, industry-leading productivity and an operational cost that will be hard to beat.”

The machine launches this month.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

The Rise of B2B in Print-On-Demand: Mastering Personalisation to Drive Growth

Rusty Pepper highlights the B2B shift in Print-On-Demand, focusing on personalisation's role in driving growth. He discusses market differences between Europe and the U.S., challenges in global scaling, and strategies for successful implementation. Experts will share insights at FESPA 2025, covering automation, fulfilment, and market trends.

Navigating the Evolving Landscape of Fashion, Print and Sustainability

In this podcast, Debbie McKeegan and April Holyome – head of Product at the luxury Italian brand 16Arlington discuss the evolving landscape of fashion at the Epson Textile Academy.

.jpg?width=550)

Awarding Talent: Joanne O’Rourke Wins the Epson Eco Stories Textile Challenge and Trip to FESPA 2025

Joanne O'Rourke won the Epson Eco Stories Textile Challenge, receiving an Epson SureColor SC-F100 printer and a trip to FESPA 2025 in May. The award highlights the importance of supporting emerging designers for a sustainable print industry. These "digital natives" drive innovation, sustainability, and technological advancement, crucial for the sector's future.

The importance of Personalisation in Direct Mail - The Power of Print

Jeroen van Druenen, CCO of Jubels discusses how personalised direct mail, especially print, boosts engagement and ROI by tailoring content to individual recipients. Using variable data printing (VDP), marketers create unique designs and offers, enhancing relevance and fostering stronger customer relationships. Physical mail's tangibility and lasting impact further amplify personalisation's effectiveness.