New and energy neutral company premises to be built for TTS due to growth

TTS have begun construction of its new company premises. TTS have seen its number of employees double, a strong increase in its international client base and its turnover has quadrupled in 10 years. These are all reasons behind the move.

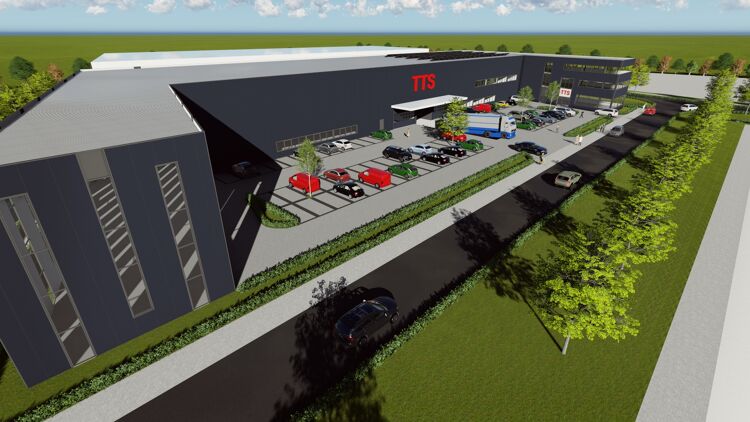

Texo Trade Services are a specialist in transfer print media and large-format printable textiles. The new, modern and completely energy-neutral building of 6,000 m2 will be completed in the Gouwe Park industrial estate in Moordrecht and is strategically situated at the Dutch A20/A12 intersection. After 10 successful years at the Coenecoop business park in Waddinxveen, TTS are expected to move in March 2019.

New services, a step up in speed and efficiency

TTS has grown exponentially in recent decades in regards of digitally-printable textile media for visual communication, digital sublimation paper and silk-screen transfer paper. The new building will enable TTS to continue to satisfy their customer demands and to further grow. There will be space to bring certain production stages in-house such as the wrapping and cutting of textiles and paper in accordance with the client’s wishes. Therefore, clients will view TTS as a one-stop-shop from here on.

In the new sample production facility, clients will have access to samples quicker and easier which will further benefit the service provision. A new addition will be the demo room that will feature various Mimaki printers, Monti calendars and transfer presses. TTS will be able to test new products and launch them to the market faster. Besides that, a loading dock guarantees that containers and goods vehicles will be handled more efficiently and quickly.

Energy-neutral

TTS puts significant importance on sustainability and due to this have decided to make its new building entirely energy-neutral. Underfloor heating, air circulation with heat exchangers and excellent insulation in conjunction with solar panels will be featured in the new building. Overall, the building has a surface area of 6,000 m2: 5,000 m2 of warehouse/commercial space twelve metres in height and 1,000 m2 of office space and demo space.

Anticipating future developments and demand

The Director of TTS, Floris Jan van den Heuvel has commented: “We foresee that the market for digital textile printing will continue to grow worldwide. Specifically, in retail and stand construction markets, more and more textiles will be used for the décor industry. However, companies who print textiles for the fashion or interior design markets are now moving to digital production. Furthermore, the application for digital sublimation printing are continuing to expand in the market for promotional items. Think in terms of hand towels, mugs, floor mats and key cords. Due to the fact that we will have more storage capacity and an effective warehouse in our new building, we will be able to operate quicker and at lower costs and will be able to respond to the growing demand from the market.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Special Effects in DTF Will Make Your “Prints” More Memorable

The DTF market is expanding with new vendors and innovations like multi-head printers enabling diverse ink options (spot, neon). Decorative films offer streamlined special effects. Keypoint Intelligence tested metallic and glitter films, noting varied ease of use and wash durability. New technology using adhesive and foil directly promises further creative advancements in DTF.

SmartHub – Expectations, opportunities and why you should attend!

The SmartHub at Personalisation Experience 2025 in Berlin will showcase personalisation and smart production opportunities across industries like textiles. Featuring a Smart Factory Trail with brands like Inkcups and Trotec, and a conference with experts discussing AI, mass customisation, and profit strategies, it offers insights into reducing waste and boosting efficiency through digital methods. Panel sessions will explore growth, automation in textiles, and smart manufacturing.

How is AI revolutionising Large Format Print?

Nessan Clearly discusses how AI in print relies on data pattern matching, already enhancing software for large format providers. He predicts that this will result in increased AI integration in workflow planning, job queue management, colour correction, image upscaling, and predictive maintenance via sensors and vision systems, ultimately streamlining operations and offering greater flexibility.

One Ink for All? Exploring Pigment in Textile Printing

Digital textile printing faces complexity due to diverse substrates requiring specific inks. The industry seeks a universal ink, with pigment ink showing potential. While traditionally for natural fibres, advancements aim to broaden its application, simplify processes by reducing pre/post-treatment, and improve sustainability, though challenges like hand feel on garments remain.