Personalisation: bridging the gap between consumer demand and modern production capabilities

_1.png?width=750)

Ahead of her talk at the Personalisation Experience 2024 conference (20th March at RAI Amsterdam, The Netherlands), Marie-Eve Lemieux, Chief Solutions Officer at Mediaclip, delves into how to bridge the gap between consumer demand for personalised products and modern production capabilities.

In the last 20 years, personalisation has come a long way from basic variable data (such as adding a name to a product) to completely individualised designs. We’ve switched from a scenario where personalisation was a nice-to-have for consumers, to one where customisation is now a necessity.

So if you aren’t already embracing a personalised approach to your product offering, you need to consider it to remain competitive. After all, it’s proven that a tailored offering will keep bringing your customers back, help build customer loyalty and enable you to achieve sustained, or even increased, profitability margins.

The world of personalisation is already much more vast than most people realise. I’ve worked in the industry for thirteen years and I’m still amazed by all the opportunities and applications that are made possible through modern technology, software and business models. So if there’s an eagerness from the end user to personalise their products and we have the capabilities to fulfil these orders, what’s stopping businesses from seizing this opportunity?

In my opinion, one of the key challenges is that most people aren’t aware of all of these incredible solutions and capabilities, so personalisation is still largely untapped. In addition, the missing puzzle piece for a lot of businesses nowadays is the pipeline, and what distribution and manufacturing should look like. They might already understand the value of personalisation, but they’re unsure of how to implement and integrate it into their business.

In a traditional business model for non-personalised products, items are designed by a brand, produced by a manufacturer and then shipped to a retailer who will make them available to the consumer. In the world of personalisation, the supply chain almost works the other way around. The consumer is now driving the value chain and the sales channels that we used to know don't necessarily apply anymore.

So it’s important to focus on how we, as an industry and as customisation solutions providers, can offer products that allow you to capitalise on the eagerness of the consumer to buy personalised products and make the most of innovative production solutions.

Thankfully nowadays there are software solutions available in the market that “bridge the gap” between consumer demand and your production workflow. With fully customisable software like our solutions from Mediaclip, printers, retailers and brands can now access the tools they need to offer personalisation options for consumers. This software enables customers to tailor their purchase in an online design suite which produces a print-ready file to be sent directly to the fulfiller, providing you with a link between your consumer and your production facilities and e-commerce workflow.

My session at the Personalisation Experience conference, titled ‘Making Sense of Connecting Production Imperatives to Consumers’ Aspirations’, will delve deeper into our customers’ success stories and how they’ve integrated personalisation into their offering. I will highlight how, as an industry, we can now easily connect on-demand production with consumer demand and explore which business model is right for you. Reviewing best practice user cases, we will also explore how the next-gen consumer experience can drive profit margins and customer loyalty while unlocking personalisation potential.

See Marie-Eve Lemieux’s session, ‘Making Sense of Connecting Production Imperatives to Consumers’ Aspirations’ at the Personalisation Experience conference on 20 March 2024, 2.15 – 2.30 pm. To register your attendance, visit www.personalisationexperience.com.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

European Sign Expo to highlight developments shaping the future of signage and visual communications

European Sign Expo 2025 (6 – 9 May, Messe Berlin, Germany) is weeks away and a host of leading exhibitors are all set to welcome Visionaries from across the signage and visual communications industries to their stands.

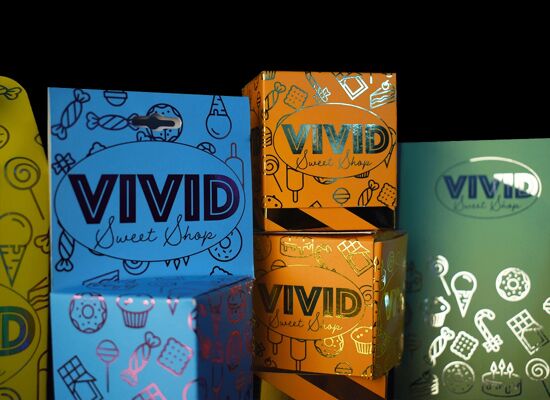

Adding sparkle to personalised print with special effects

With demand for personalisation on the rise, Rob Fletcher looks at how offering customers the option to add special effects to their printed work can help you win new business and expand into new markets.

Kernow Coatings to showcase innovative solutions at FESPA 2025

Kernow Coatings will showcase innovative, sustainable wide-format printing solutions at FESPA 2025. Highlights include a collaboration with Ricoh for a space-themed booth, featuring KernowJet MetaliK and Interiors Structured Silver. They'll also present recyclable wallcoverings and PVC-free media, emphasizing high-performance, eco-friendly options.

Understanding the differences and similarities between monitor and RBG Device ICC Profiles

Paul Sherfield explores the the intricacies of RGB monitor profiles and RGB device profiles, uncovering the challenges and considerations that we can face in the colour management field face daily.