Roland DG launches ‘secret weapon’ for textile print

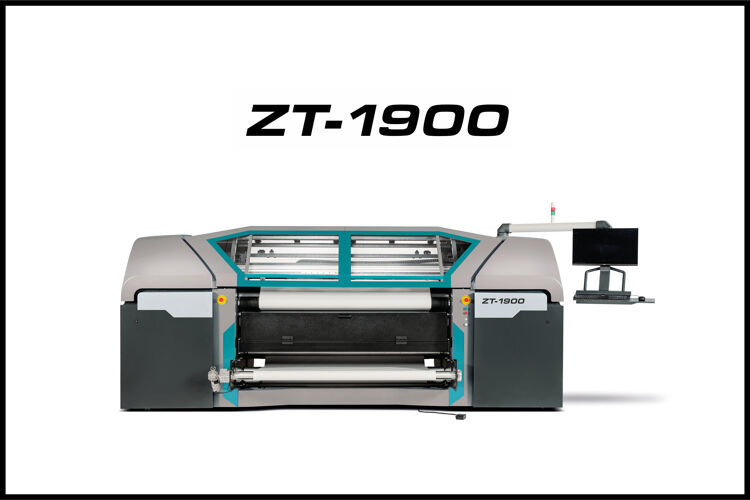

Roland DG has announced the launch of the ZT-1900, its largest textile printer to date that it said will help users take advantage of a number of major trends in the market.

The 1.9m-wide dye-sublimation printer offers users the ability to print at speeds of up to 220sqm/hr in draft mode and 150sqm/hr in production mode, while it also has a mirrored CMYK configuration for increased productivity.

Other features on the new machine include an integrated infrared dryer, which Roland DG says allows for faster drying, as well as a 5kg ink container capacity and control software, allowing for ripped files to be printed repeatedly and for the re-printing of the same jobs quickly.

Four high-precision double-channel Kyocera printheads deliver what Roland DG described as “fine detailed text, superior image quality and vibrant solid colours”, while the manufacturer’s own high-density dye-sublimation inks produce a wide colour gamut and are compatible with coated and uncoated papers.

Speaking to FESPA.com about the new launch, Encarna Luque, senior product manager inks and business development textile and decoration at Roland DG EMEA, said the ZT-1900 can be the secret weapon for many businesses looking to grow in the busy textile print sector.

“Firstly, business that use analogue methods but are hoping to take the leap into digital printing with a high-productivity, high-quality system will benefit,” Luque said. “Secondly, companies already using digital sublimation printers will be able to quickly boost production to meet new orders.

“The product will rapidly help businesses grow by diversifying their offering to existing customers. With its wider range of applications and compatible dye sublimation papers, users can branch into the fashion, sportswear, interior décor and soft signage sectors.”

In terms of the type of work users can run on the new ZT-1900, Luque pointed to the growing personalisation trend, which she said shows no signs of slowing as consumers want to create their own, uniquely designed and decorated items.

“The ZT-1900 has impressively low running costs and efficient ink performance meaning the printer will provide a quick and positive impact on the balance sheet,” Luque said.

“The heavy-duty feeding system can use mini-jumbo rolls meaning businesses can instantly reduce paper costs, increase uninterrupted printing and enable unattended printing to free up staff. It is also possible to replace ink without stopping the printing process.”

Luque added: “We hear time and time again the industry demands equipment with low running costs with uncompromised quality. Our research and development team has used the latest technology to create a printer that does exactly that.”

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

The importance of ink for large format printers

Ink is crucial for large format inkjet printers, influencing substrate compatibility, productivity, and cost. Nessan Cleary discusses the three main types which include UV-curable ink, latex ink and eco-solvent ink. Each ink type has specific strengths and weaknesses, making printers choice dependent on budget and intended applications.

What are the benefits of Direct-To-Fabric printing?

Direct-to-fabric printing is gaining popularity for high-volume textile production, enabling on-demand, customized short runs. These printers offer ink flexibility, accommodating various fabric types like cotton and silk, though ink development focuses on faster turnaround by reducing pre- and post-processing. Compared to traditional methods, direct-to-fabric inkjet printing is a more sustainable option due to reduced water and chemical usage, and localized production.

What are the opportunities for large format providers regarding digital touch screens?

Digital touchscreens are becoming increasingly common, offering businesses opportunities to improve customer engagement and streamline operations. Nessan Cleary shares, while more expensive to implement than standard digital displays due to complex software and integration needs, touchscreens provide self-service options, multilingual support, and can reduce staffing costs in various settings like retail, transportation, and healthcare.