The evolution of automated digital cuttting tables

Nessan Cleary shares how digital cutting tables are evolving into highly automated finishing systems. There is a focus on reducing the number of operators required to manage production by taking out the main bottleneck.

Digital cutting tables have long been seen as a must-have accessory to go alongside flatbed and hybrid printers. Over the years we have seen a number of enhancements, such as larger tables and conveyor belts to speed up productivity, as well as a greater range of cutting tools, and more powerful spindles that are able to handle a wider range of materials.

Despite this, there have been a relatively small number of companies manufacturing such systems. However, this has been changing over the last few years with a number of new players, mainly from China, offering budget-friendly cutting tables. For the most part, these have gained a good reputation for quality and reliability and systems from vendors such as JWEI and iEcho are starting to appear in numbers in print shops worldwide.

This in turn has meant that the more established manufacturers have had to expand their offerings and diversify into other markets. Several manufacturers used this year’s FESPA exhibitions to demonstrate large, highly automated cutting systems. These match developments in flatbed printers, that is, towards larger bed sizes, with much higher productivity and targeting the packaging as well as display graphics markets.

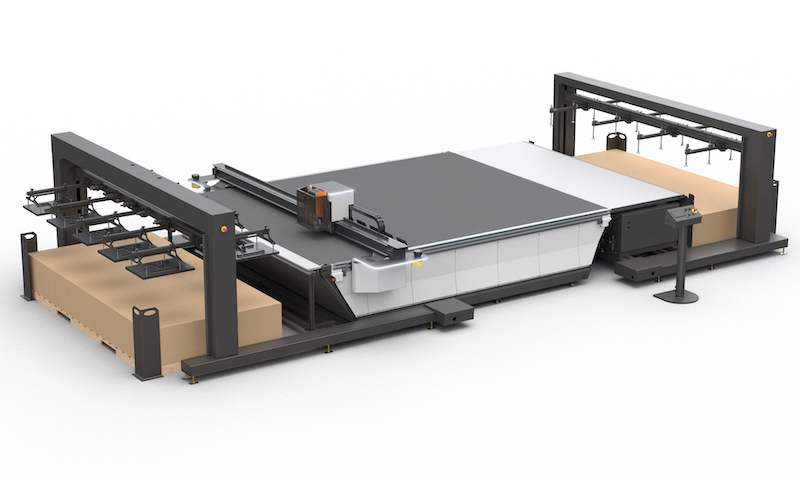

Caption: The new Kongsberg Ultimate cutting table, seen here with automated feeder and stacker units. Image credit: Kongsberg.

Caption: The new Kongsberg Ultimate cutting table, seen here with automated feeder and stacker units. Image credit: Kongsberg.

Kongsberg PCS was formerly a division within Esko until it was spun off as a separate company. It’s latest offering for the graphic arts market is the Ultimate, which is available in four sizes with the first three having widths of 1680 mm, 2210 mm and 3210 mm, all with a table length of 3200. The largest 66 size has a work area of 3210 x 4800 mm. They all take materials up to 30mm in thickness, and all have eight vacuum zones with the option to split the table in half to work on one side while loading or unloading boards on the other.

It uses a high torque Infinite linear motor drive system combined with a rack and pinion set-up, which gives a maximum linear speed for all models of 167.5 mpm. The two largest models use a carbon fibre beam, which gives a good balance between low weight and high stiffness for more precise cutting, while the smaller models use an aluminium beam. The larger models can produce 50Kg of downforce from the beam, which should ensure more precise cutting.

All four models in the Ultimate series can be used with or without a conveyor belt while the largest two models can also be configured with a automated feeder and stacker for either simultaneous or sequential production.

Kongsberg has a new robotic material handling option. This is mounted on rails and has seven axes to give it multiple loading and unloading points to cope with several tables.

Kongsberg is also looking to diversity into other markets. It’s latest product is the C68 Exact, which has been developed as a design tool for industries such as aviation. This is really more of a drafting table with some light cutting capability.

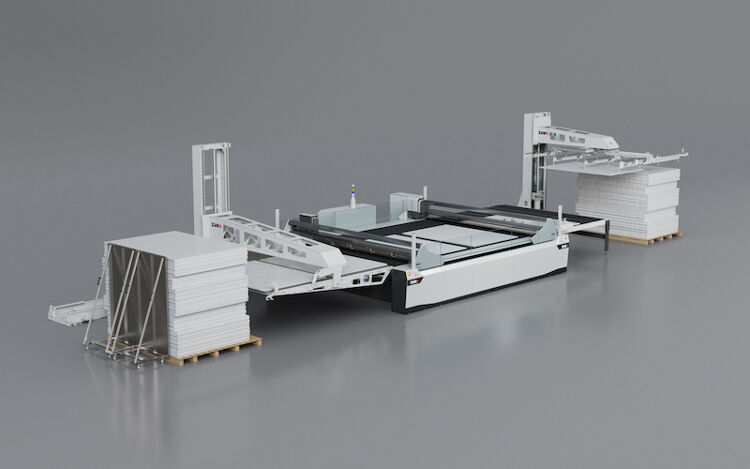

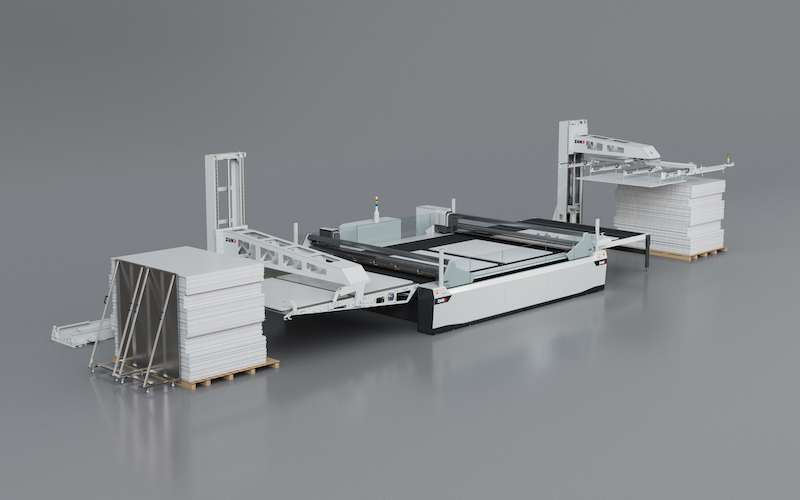

Caption: Zund’s new Q-line digital cutters comes with automated loading and unloading. Image credit: Zund.

Caption: Zund’s new Q-line digital cutters comes with automated loading and unloading. Image credit: Zund.

Zund has also turned to greater automation with its most recent product launch, the Q-Line with the Board Handling System BHS180. The Q-Line cutter is built on a concrete substructure for stability. The tables come with two beams for increased productivity, which are made of carbon fibre-reinforced plastic for low weight and strength. It uses a linear drive system that can accelerate at up to 2.1g and the system can run at up to 2.8m/sec. Jobs are processed via QR codes, which means that it can handle a variety of different jobs in the stack.

The Q-series all come with a 3.2m long table but there’s a choice of three widths. The Q 32-32 D has a working width of 3.2m, while the Q 22-32 D is 2.2m wide and the Q 18-32 D is 1.8m wide. They will take boards from 0.9 up to 65mm thick.

The BHS180 board feeder has an integrated UnderCam camera that picks up the location of the image printed on the board and can compensate for any distortions in the print to match the cut to the print. With every scan, the software adjusts the cut paths to the printed image, on the fly and in real time, reducing the cycle time for each job. This UnderCam system is also now available for use with Zund’s existing G3 cutting tables.

Zund has also adapted some of its systems for cutting textiles, so that they can take printed textiles and automatically cut out patterns for garments or furnishings. Zund has recently introduced a new Roll Handling System, the RHS6-50, which can hold up to six rolls of textiles weighing 50 kg each. The rolls can then be fed to the cutting tables for uninterrupted production.

Elitron used this year’s Fespa show to introduce a new automated loading and stacking system called Kumula, which was demonstrated with the Kombo SDC+ conveyor cutting system. The idea is to reduce the amount of time that an operator needs to spend with the machine, since the finished jobs can be automatically stacked neatly.

Caption: Elitron has added this Kumula loading and stacking system to its Kombo SDC cutting system. Image credit: Elitron.

Caption: Elitron has added this Kumula loading and stacking system to its Kombo SDC cutting system. Image credit: Elitron.

Elitron's updated version of its Kombo Tav cutting table features an integrated palette loading and unloading system. Elitron has updated the control board and electronics, which should lead to up to a 35 percent increase in speed as well as cutting its energy consumption.

Elitron has also introduced a new compact cutting table, the Spark, which is mainly designed for sample making as well as some graphics work. It’s fitted with a multi-tool cutting head and vision system.

Mimaki also showed off a new CFX series of cutting tables at this year’s Fespa show in Amsterdam. There’s a choice of four models, all 2.5m wide but with lengths from 1.3 to 5m, with some clearly designed to match up with Mimaki’s JFX600 series of flatbed printers. The CFX models can be fitted with up to four types of tools to minimise tool changing.

In conclusion, this level of automation is about reducing the number of operators needed to manage production by taking out the main bottleneck - getting the boards on and off the cutting tables - in order to compete on higher productivity rather than lower prices.

To discover the latest content that covers a wide range of sectors including cutting, automation and finishing sign up for FESPA’s free monthly newsletter FESPA World available in English, Spanish and German.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

The importance of Personalisation in Direct Mail - The Power of Print

Jeroen van Druenen, CCO of Jubels discusses how personalised direct mail, especially print, boosts engagement and ROI by tailoring content to individual recipients. Using variable data printing (VDP), marketers create unique designs and offers, enhancing relevance and fostering stronger customer relationships. Physical mail's tangibility and lasting impact further amplify personalisation's effectiveness.

What are the current trends for digital screens?

Digital screens are evolving rapidly, moving beyond simple signage. MicroLED technology improves resolution and efficiency, while 3D and AR displays offer immersive experiences. AI is transforming content creation and analytics, personalising interactions and optimising screen placement. Larger, wall-sized screens and temporary rentals at events are becoming more common. As screens become ubiquitous, innovation focuses on eye-catching solutions to maintain audience engagement.

Hints and tips for vehicle wrapping success

While rising demand for vehicle wrapping is good news for the industry, this is placing more pressure on companies to deliver quality work at a solid pace. Here, Rob Fletcher picks up some tips from several experts in this sector to help wrappers operate smoothly.

What are the opportunities in Personalisation for Sportwear and Signage?

Rob Fletcher discusses the growing importance of personalisation and digital innovation across sectors. Major brands use personalised print to engage customers and boost sales. Personalised sportswear demand is increasing, and companies like Eurojersey embrace sustainable manufacturing and digital transformation.