The growth of the Digital Textile Print Bureau

Debbie McKeegan discusses how digital textile printing, web to print software and vibrant ecommerce platforms have contributed in the growth of the Digital Textile Print Bureau across most textile applications.

No single shift in the Textile Business Model can have had more impact than the logarithmic growth of the Digital Textile Print Bureau. This market is driven by Millennial demand, where Customisation and Personalisation are paramount, along with the speed and instant customer satisfaction generated by Digital Textile Printing.

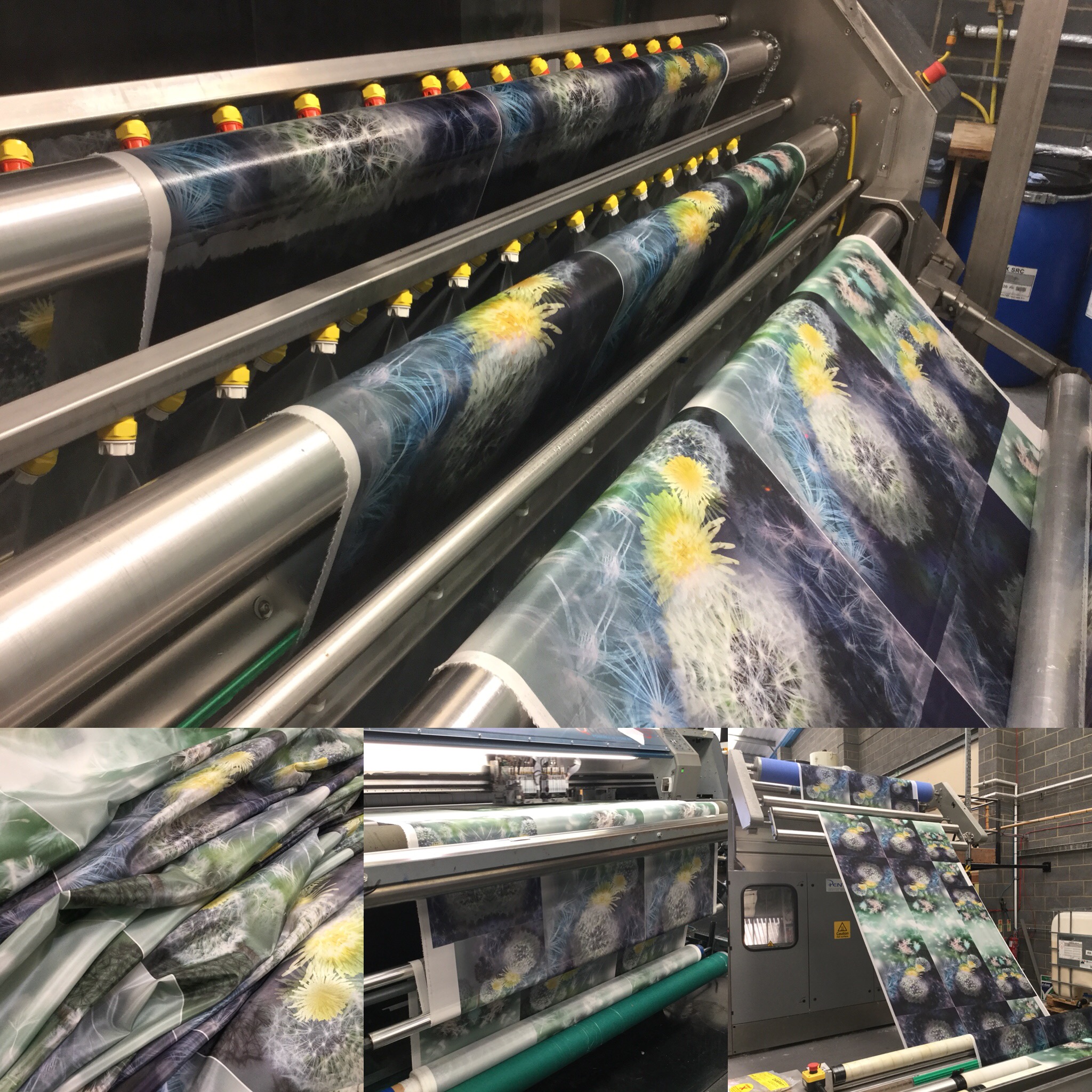

Caption: The Silk Bureau Limited is family owned business with more than 30 years’ experience. Founders Doug & Elaine Davies met at Art College and are both talented artists in their own right. Offering custom printed digital fabrics for individual designers, textile design studios and international retailers serving the Fashion and Home Décor industries. Credit: Leila Vibert-Stokes the ‘Greenfields Design a Scarf’ Competition winner & The Silk Bureau Ltd.

Caption: The Silk Bureau Limited is family owned business with more than 30 years’ experience. Founders Doug & Elaine Davies met at Art College and are both talented artists in their own right. Offering custom printed digital fabrics for individual designers, textile design studios and international retailers serving the Fashion and Home Décor industries. Credit: Leila Vibert-Stokes the ‘Greenfields Design a Scarf’ Competition winner & The Silk Bureau Ltd.

Fuelled by three enablers, Digital Textile Printing, Web to Print Software and Vibrant Ecommerce Platforms, the growth of the Digital Bureau crosses most Textile Applications, where it has generated huge potential from start-ups all the way through to mass manufacture. Success stories abound, and so it is difficult to single out any particular sector for mention, and yet, common to all of them, is the availability of sophisticated print machinery, and the upsurge in demand for customisation and personalisation.

None more so than in the DTG (Direct to Garment) sector, where machine prices and speeds cater for all needs. At one end of the market, a newcomer to the industry can set up a decent print shop and ecommerce business for well under £20k.

Entry level machines are popular, with Roland being the latest newcomer to the DTG machine market with the launch of their BT-12, aimed at small start-up businesses with limited budgets.

.jpg?lang=en-GB) Caption: Prinfab was started in January 2016 by two brothers. Serving the creative community, they offer a range of fabrics for the Fashion and Décor industry, and have built a state-of-the-art production facility using the latest digital fabric printing technology. Credit: PRINFAB LTD.

Caption: Prinfab was started in January 2016 by two brothers. Serving the creative community, they offer a range of fabrics for the Fashion and Décor industry, and have built a state-of-the-art production facility using the latest digital fabric printing technology. Credit: PRINFAB LTD.

At the other end of the market, Hi-Speed DTG machines such as the Atlas, recently launched by Kornit, offers a potential daily production in excess of a 1,000 units of personalised T-Shirts.

The machines on offer come with embedded design and workflow software, making it easy to meet an Ecommerce demand for customisation and personalisation. Installation of the machinery is not complicated, service support is widespread and, as the supplier base for blanks expands, so these businesses are moving from strength to strength.

The DTG Bureau can give 24 hr supply from one to one thousand t-shirts, all unique and individual, catering to and satisfying the huge demand for customisation.

Although the DTG market was a trailblazer, the real explosion in growth is in the production of bespoke fabrics in the Roll to Roll market.

Here, the bureau is not confined to producing prints on blanks, but creates unique fabrics on the roll that can then be used in a myriad of applications from Fashion to Homewares and from Craft to Interior Design.

Roll to Roll Bureaus are springing up in every country as the technology becomes more available and easy to use.

At its simplest level, the Roll to Roll Bureau is often a ‘one man band’ employing only two or three people, and yet, with Digital Textile Printing technology, capable of beating much larger enterprises to the punch when it comes to Service, Delivery and Price.

Caption: Print Unlimited offer a vast range of digitally printed fabrics for fashion, sports and beachwear, the entertainment industry, and Home Décor. Based in Holland they manufacture high quality digital textile prints in the quantity that you need and on the fabric of your choice. Credit: Designer Lucie Loete and PrintUnlimited.

In this entry-level Bureau, all the skills are present through multi-task training from Design to Pre-Press and on to Printing, Inspection and Dispatch. Typically they cater for a broad base of demand.

Up and coming Fashion Designers who need urgent prints of a few metres to complete their collection, Craft Businesses who need swift supply to minimise their stocks and maximise their sales, and Interior Designers who need a few exclusive metres of fabric for that never to be forgotten look.

All of these and more come to the Entry Level Bureau, where there is a wide spread of available technologies and fabric availability. Many of these Bureau’s offer over 50 Standard fabrics and a full range of printing ink-set options from Latex to Dyesub and from Reactive to Pigment.

Again, in the Roll to Roll sector machinery choices are many: Entry level machinery is available from Mimaki, Roland, Epson, Mutoh, HP, Pigment Inc, Fabrijet and D-gen, to name just a small selection, and all supply efficient, fast and high quality production machines, which cater to the speed and variability of demand which is a feature of this sector.

In many cases Bureau’s work with simple workflow software based around Adobe Photoshop for Design, and RIPs (Raster Image Processing Software) supplied by the manufacturer. Yet, however simple the system it gives the entry level printer the ability to manoeuvre images and print quickly and accurately to satisfy the requirements of their clients who need Customisation and Personalisation in a hurry.

But it would be a mistake to think of the Digital Textile Bureau as only a small scale enterprise, for this business model has created leviathans as well, and none exemplifies this more than the American giants Spoonflower and Merch by Amazon.

Spoonflower reputedly processes over 4,000 orders a day of two yards or less, taking designs from their clients and delivering finished product to them within a day or two. Spoonflower’s Roll to Roll business uses a variety of machinery printing with a number of ink-sets, however the offer is always the same, just the quantities are higher.

Similarly at Merch by Amazon, which is basically a DTG Bureau offering, a wide range of products, individual design, and the rapid delivery that Amazon is so renowned for.

So, whether a large Industrial Enterprise, or a more modest Local Print Shop, the message is the same, Customisation, Personalisation and Delivery, are the mantras for the Digital Textile Printing Bureau in the proliferation of Individual Textile Design.

Visit FESPA’s Print Make Wear at the Global Print Expo 2019 to see the latest technology in textile production for fashion, showing both direct to garment and roll-to-roll workflows. The feature will host a live production line but also a catwalk and tours. Register now and use code FESM906 for free entry.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

The importance of ink for large format printers

Ink is crucial for large format inkjet printers, influencing substrate compatibility, productivity, and cost. Nessan Cleary discusses the three main types which include UV-curable ink, latex ink and eco-solvent ink. Each ink type has specific strengths and weaknesses, making printers choice dependent on budget and intended applications.

What are the benefits of Direct-To-Fabric printing?

Direct-to-fabric printing is gaining popularity for high-volume textile production, enabling on-demand, customized short runs. These printers offer ink flexibility, accommodating various fabric types like cotton and silk, though ink development focuses on faster turnaround by reducing pre- and post-processing. Compared to traditional methods, direct-to-fabric inkjet printing is a more sustainable option due to reduced water and chemical usage, and localized production.

What are the opportunities for large format providers regarding digital touch screens?

Digital touchscreens are becoming increasingly common, offering businesses opportunities to improve customer engagement and streamline operations. Nessan Cleary shares, while more expensive to implement than standard digital displays due to complex software and integration needs, touchscreens provide self-service options, multilingual support, and can reduce staffing costs in various settings like retail, transportation, and healthcare.