What is digital textile printing and what are the opportunities?

Nessan Cleary shares how textile printing covers a wide range of different market sectors which vary in opportunities. Nessan discusses sportswear, direct to garment and home décor.

There are numerous reports and articles claiming that digitally-printed textiles is one of the fastest growing markets within printing and pointing out that there are huge opportunities for further growth. However, ‘textile’ should really be seen as an umbrella term that covers several different market areas. The basics may be similar but there is considerable variation in the scale of the opportunity, the type of knowledge and equipment needed as well as the optimum way to reach the customers for each of these different markets.

Caption: This EFI FabriVu 340i is a textile printer designed for soft signage and featuring an inline fixation unit.

Caption: This EFI FabriVu 340i is a textile printer designed for soft signage and featuring an inline fixation unit.

For many people working in wide format, the obvious starting point will be soft signage using fabric instead of a plastic-based film. This includes flags, banners and backlits as well as exhibition stands. There’s an obvious environmental benefit as textiles are easier to recycle, and also easier to transport and to clean for re-use. Soft signage is particularly well suited for interior graphics such as for retail or exhibition use, and can be treated for flame retardance to comply with fire regulations.

For many signage applications you could just print direct to any suitable textile material with a standard roll-fed printer, using either UV-curable or latex inks. But for most applications the most suitable fabric to use is polyester, which is light weight so that it’s easily installed as well as being relatively cheap. The best way to print to polyester is through dye sublimation. This normally involves printing to a transfer paper and then running the paper together with the substrate through a heat press or calendar that will apply heat and pressure to force the ink to sublimate from the paper into the polyester fibres. This requires a degree of skill and some time to do properly.

However, an alternative is to use direct sublimation that involves printing direct to the final substrate. These printers usually have a heat source - typically infrared lamps - built in to sublimate the ink between the printer and take-up winder. The print results are not quite on a par with the standard dye sublimation approach but more than good enough for signage applications. More to the point, the printing and sublimation is a single process so it is easier and quicker, and therefore cheaper, to produce.

Fashion and sportswear

Then there is the apparel market, which itself spans several different approaches from sportswear to high fashion. Sportswear is an easy place to start in apparel because it’s dominated by polyester, which is handy for anyone who already has a dye sublimation printer.

In theory, it’s possible to do both sportswear and soft signage from a single dye sublimation printer. However, in practice you will really need a 3.2m wide printer for soft signage and it will probably be most efficient to print direct to the substrate. In contrast, a 1.3m or 1.6m wide printer will be quite adequate for garments but you should print via transfer paper because this will produce a much better hand feel.

When it comes to other types of fabric, there are specific inks available. There is considerable market pressure to develop a single type of ink for all types of fabric. Most textile inks will work across several different types of fabric, but you will get best results if you match the ink with the fabric it was designed for though the individual applications will determine how far you can push the print quality. For example, silk scarves aimed at the higher end of women’s fashion will be best produced with acid dye ink, while pigment inks work best with cotton and natural fibres but can also be used with linen, rayon, silk, wool, nylon and polyester. Many textile printers operate several printers with different ink sets.

In most cases there will also be some degree of pre- and post-treatment needed, which could include several cycles of washing, steaming and ironing and can significantly affect the overall productivity. Most recent developments in textile inks have been about reducing the extent of this treatment but sometimes this comes at the expense of the hand feel of the fabric.

Going direct

It’s relatively easy to get into the short run clothing market by investing in a Direct-to-Garment machine. Most types of printing involve laying down the ink onto a blank substrate and then converting this into a finished product. But the advantage of DtG is that the product - usually a t-shirt - has already been manufactured and just needs to be decorated.

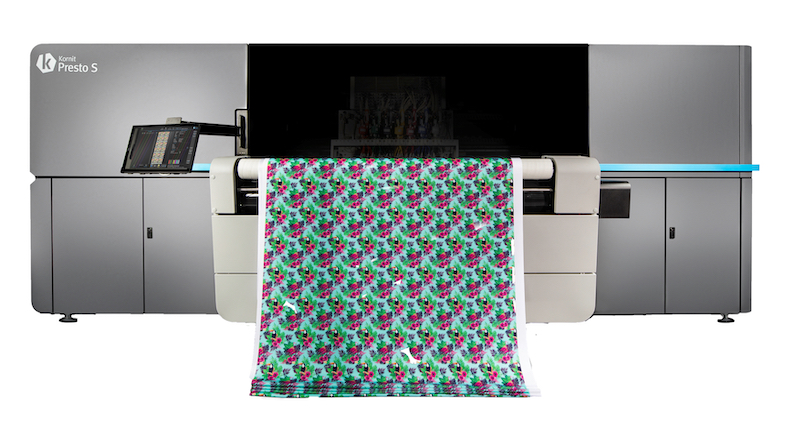

Caption: The Kornit Presto is a 1.8m wide roll-fed direct to fabric inkjet printer.

Caption: The Kornit Presto is a 1.8m wide roll-fed direct to fabric inkjet printer.

Until relatively recently, DtG has been limited to more natural fibres such as cotton. This is because the fibres in polyester are thinner and more slippery than with natural materials, which makes it harder to get the ink to adhere to them. But both Kornit and Ricoh now also offer DtG printers that can print to polyester, which is helping to further open up the sportswear market.

There are really two business models here. Most DtG printers are table top machines so that the overall productivity is limited to how fast the operator can load and unload the garments. However, that also includes the time needed to run the garments through a heat press to complete the printing process.

Caption: This Ricoh Ri4000 DtG printer has been designed to print to polyester.

Caption: This Ricoh Ri4000 DtG printer has been designed to print to polyester.

But where the business entirely revolves around producing printed items then you will need a more automated solution such as those made by Kornit or Aeoon, or a hybrid screen printing machine that can handle higher volumes. These printers can be matched with a drying tunnel that will lead to much higher productivity.

In recent years the Direct-to-Film approach has become very popular. This involves printing the graphic to a film that can be applied separately to a product. These printers are usually sold as a complete DtF solution that includes the printer and powder shaker. They are capable of decent productivity for a relatively modest outlay. They can be used for t-shirts but are particularly effective at adding corporate logos to promotional items.

Home decor

Apparel, and particularly fashion, may well be the most glamorous aspect of textile printing. But there is also a very healthy market opportunity in home decor and furnishings. This includes curtains, duvets, sofa coverings, cushions and tablecloths. These are all areas that can benefit from short run designs and personalisation. They can be sold direct to consumers or business such as local hotels and restaurants, as well as to retailers.

The temptation is to see apparel and furnishing as the same market since you are printing to broadly similar fabrics. In theory pigment inks should enable you to print to any textile with the minimum of pre-treatment and with very little washing and steaming required. In practice, many pigment inks produce a more coarse texture because the ink sits on the fabric rather than soaking into the fibres. This is acceptable for some garment applications such as a logo on a jumper. But consumer will expect that any kind of clothing that is worn close to the skin has a soft and pleasant feel, and will expect those items to last through many different wash cycles. However, texture is less critical for home decor applications and consequently these printers, particularly the larger 3.2m wide machines, generally target the furnishings market.

In conclusion, there is a huge market opportunity in digitally printed textiles but largely because it’s actually several different markets. The print technology may be similar across these markets, but this is only one half of the game. The other half, the customers and their expectations, as well as the sales channels will be very different and require different skillsets.

Discover the latest innovations in textile printing and garment printing at FESPA Global Print Expo 2025, Europe's leading print and signage exhibition taking place from 6 - 9 May at Messe Berlin, Germany. It will showcase the most innovative products, visionary concepts, and latest developments in the future of print. Register your interest to visit here.

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Kernow Coatings to showcase innovative solutions at FESPA 2025

Kernow Coatings will showcase innovative, sustainable wide-format printing solutions at FESPA 2025. Highlights include a collaboration with Ricoh for a space-themed booth, featuring KernowJet MetaliK and Interiors Structured Silver. They'll also present recyclable wallcoverings and PVC-free media, emphasizing high-performance, eco-friendly options.

Understanding the differences and similarities between monitor and RBG Device ICC Profiles

Paul Sherfield explores the the intricacies of RGB monitor profiles and RGB device profiles, uncovering the challenges and considerations that we can face in the colour management field face daily.

From Imagination to Fabric: Exploring Generative AI with ROQ and Printbox

ROQ and Printbox's upcoming session at SmartHub Conference at Personalisation Experience will demonstrate real-time AI-powered t-shirt personalisation. Attendees will be able to create designs with AI, printed live on ROQ's DTG printers. This will showcase the power of combining generative AI with on-demand printing, revolutionising customer experience and apparel customisation.

GCC LaserPro at FESPA 2025: Pioneering the Future of Speed and Precision

GCC, a leading front-end R&D company, established its brand, GCC LaserPro, to drive innovation in laser engraving and cutting solutions. We are excited to showcase our latest advancements at FESPA 2025 in Berlin!