What is the potential of label printing?

There is a lot of potential for digital printing in label print for packaging and industrial applications. Sonja Angerer shares the upcoming trends that printers should be aware of.

Is there growth potential regarding label print? Consultants from Market and Research have just presented a study in which label printing markets are estimated to grow 4.9% CAGR. By 2027, the global sales volume in label printing is expected to reach $58.8 billion.

Therefore, it is not surprising that many manufacturers of printing presses are increasingly developing new machines and technologies for label printing. At global exhibitions in 2023, here were the top 3 trends that will be discussed within this article:

- Automation

- Cooperation

- Environmentally friendly and safe printing

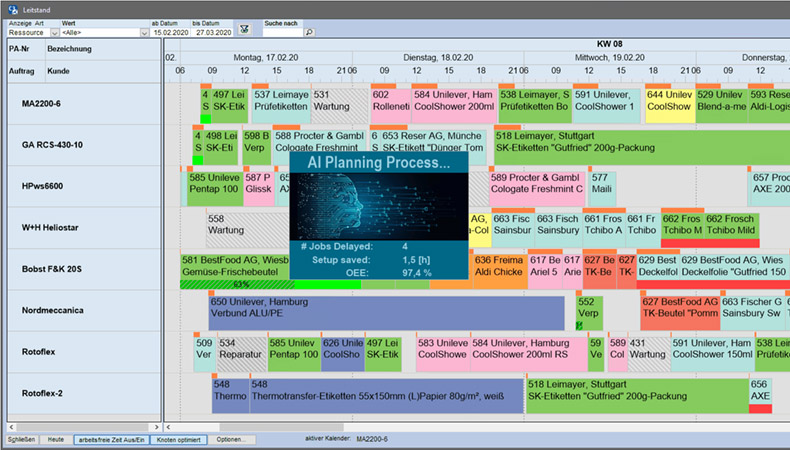

CAPTION: Theuer.com has unveiled an AI-powered module for fully automated production planning in label printing. Image Credit: Theurer.com

CAPTION: Theuer.com has unveiled an AI-powered module for fully automated production planning in label printing. Image Credit: Theurer.com

Automation in label printing

The topic of "automation" is currently very popular in the printing industry. With the increasing pressure on margins, high costs for raw materials and labour, and increasingly small-scale print jobs leave companies with not much choice.

In addition to process optimisation, software is the focus of automation solutions. Many factors have changed in recent months: Artificial intelligence (AI) is increasingly helping to make processes faster and easier. Theuer.com, for example, has created a module that enables fully automated production planning in label printing, but also in other segments of the printing industry.

The shortage of skilled workers has led to less qualified personnel in the pressroom. So, software used in automation processes must be as intuitive as possible. Zünd has completely revised its interface for the Cut Centre in version 4 and optimised it for use on touchscreen devices. The modular software can be configured for data exchange with other solutions, such as universal RIPs or MIS/ERP systems.

CAPTION: Simplified software interfaces, such as version 4 of the Zünd Cut Center, allow production with fewer skilled workers. Image Credit: Zünd

CAPTION: Simplified software interfaces, such as version 4 of the Zünd Cut Center, allow production with fewer skilled workers. Image Credit: Zünd

Collaborations for label printing

Complex workflows in label printing are rarely optimised with the products of just a single manufacturer. As a result, effective cooperation is becoming more common. For example, eProductivity Software recently announced that ePS Radius ERP is now compatible with HP Indigo. Through the integration between the Packaging Suite and HP Indigo PrintOS, the entire process from order to job costing, planning, prepress and scheduling can be fully automated.

Konica Minolta will also be showcasing its end-to-end ecosystem at trade fairs with the AccurioLabel 400 single-pass label printing system as a highlight. For further processing, JETvarnish 3D Web 400 and Octopus Web from MGI or DC330Mini from Grafisk Maskinfabrik (GM) are used. Comprehensive software suites such as AccurioPro Flux Label Impose and Accurio Pro Dashboard ensure that every step of the process can be tracked.

Screen and Nilpeter presented a similar approach to label printing and finishing in Brussels in September 2023. The aim of this partnership was to meet the changing requirements of the label and packaging industry and to deliver reliable and high-quality combination printing for value-added labels.

CAPTION: Xeiko Eco-Toner is designed to make label production more environmentally friendly. Image Credit: Xeikon

CAPTION: Xeiko Eco-Toner is designed to make label production more environmentally friendly. Image Credit: Xeikon

Environmentally friendly and safe labels

Digital printing has become the most important technology in packaging printing due to powerful machines such as the EFI Nozomi family in the food industry and elsewhere.

Fujifilm has therefore introduced CuremaX IDFC. The new high-gloss LED UV printing ink has been specially developed for food and pharmaceutical packaging and direct contact with the contents. According to the manufacturer, there is only a minimal migration risk. CuremaX IDFC is suitable for narrow-web label printing, from self-adhesive labels and films without backing material to bags for wet items and shrink sleeves.

In the future, labels and packaging should be easier to recycle and, from renewable sources. Xeikon and Sappi announced a partnership in August 2023 to develop such print media. Xeikon TITON technology makes it possible to protect products without the need to apply a primer or varnish after printing. In line with this, Xeikon also recently announced a vegan eco-toner for the Cheetah label printers.

Label Print: A market niche for printers?

The growth prospects in label printing remains stable. However, large brands in the consumer market require high quantities at low margins. As a result, this segment is already well occupied by major international suppliers.

However, the increased use of AI in the printing and design industry is likely to make the use of customised labels and packaging worthwhile for small businesses and even cottage industries. After all, handmade, regional, and personalised products are in vogue.

For legal reasons alone, also small companies will need professional labels in the years to come. There are still many market opportunities here, especially for local printers.

To discover the latest content that covers a wide range of sectors including labels, digital printing and AI sign up for FESPA’s free monthly newsletter FESPA World available in English, Spanish and German.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

The importance of ink for large format printers

Ink is crucial for large format inkjet printers, influencing substrate compatibility, productivity, and cost. Nessan Cleary discusses the three main types which include UV-curable ink, latex ink and eco-solvent ink. Each ink type has specific strengths and weaknesses, making printers choice dependent on budget and intended applications.

What are the benefits of Direct-To-Fabric printing?

Direct-to-fabric printing is gaining popularity for high-volume textile production, enabling on-demand, customized short runs. These printers offer ink flexibility, accommodating various fabric types like cotton and silk, though ink development focuses on faster turnaround by reducing pre- and post-processing. Compared to traditional methods, direct-to-fabric inkjet printing is a more sustainable option due to reduced water and chemical usage, and localized production.

What are the opportunities for large format providers regarding digital touch screens?

Digital touchscreens are becoming increasingly common, offering businesses opportunities to improve customer engagement and streamline operations. Nessan Cleary shares, while more expensive to implement than standard digital displays due to complex software and integration needs, touchscreens provide self-service options, multilingual support, and can reduce staffing costs in various settings like retail, transportation, and healthcare.