Zünd now cuts both ways, knife and laser

In a move that is sure to shake up the digital textile area, Zünd has introduced the LM 100W Laser Module, to cut and seal polyester fabrics in one efficient process.

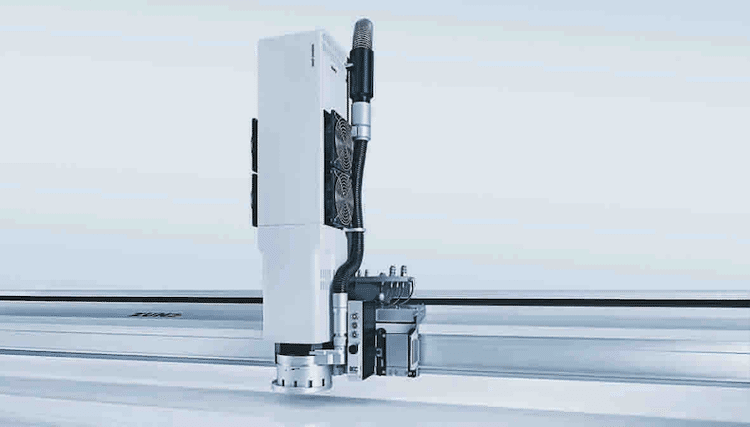

Because of the modular head system employed on Swiss-made Zünd cutting tables, users can switch between many cutting modes plus routing, and now laser cutting and sealing. This addition further amplifies the versatility of Zünd's modular, wide-format cutting systems.

“Textiles offer lightness, versatility, excellent colour rendition and handling for soft signage, theatrical backdrops or back-lit applications,” comments a representative from the company.

“Edge-fraying has sometimes been a problem with solutions such as ‘hot knives’ and seam-sewing offering a partial remedy. Now with Zünd’s new LM 100W Laser Module, textile printers can cut and seal edges all in one go.”

Zünd itself claims that soft signage offers tremendous potential in the vast and diverse world of visual communication media. Polyester fabrics are beginning to conquer applications previously ruled by paper and PVC substrates.

To facilitate cutting this material, Zünd has developed the LM 100W laser module, that is designed to cut polyester textiles and simultaneously seal the edges.

The LM 100W automates what has long been a separate, manual operation and thereby also eliminates the need for seaming. The LM 100W also delivers impeccable cut quality repeatability because laser cutting is a touch-free process and no hold-down is required during processing.

In minutes, one operator can convert a Zünd cutter to a full-blown laser-cutting system in a few simple steps. Once the laser job is completed, it is just as easy to reconfigure the cutter with modules for knife-cutting, passé partout or routing.

The Zünd laser module is equipped with an air-cooled CO2 100W laser with a processing speed of 44m/144 ft per min. As a Class one laser, it requires no special safety gear such as protective glasses. The laser module is fully enclosed, which provides reliable protection for the operator.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

The importance of ink for large format printers

Ink is crucial for large format inkjet printers, influencing substrate compatibility, productivity, and cost. Nessan Cleary discusses the three main types which include UV-curable ink, latex ink and eco-solvent ink. Each ink type has specific strengths and weaknesses, making printers choice dependent on budget and intended applications.

What are the benefits of Direct-To-Fabric printing?

Direct-to-fabric printing is gaining popularity for high-volume textile production, enabling on-demand, customized short runs. These printers offer ink flexibility, accommodating various fabric types like cotton and silk, though ink development focuses on faster turnaround by reducing pre- and post-processing. Compared to traditional methods, direct-to-fabric inkjet printing is a more sustainable option due to reduced water and chemical usage, and localized production.

What are the opportunities for large format providers regarding digital touch screens?

Digital touchscreens are becoming increasingly common, offering businesses opportunities to improve customer engagement and streamline operations. Nessan Cleary shares, while more expensive to implement than standard digital displays due to complex software and integration needs, touchscreens provide self-service options, multilingual support, and can reduce staffing costs in various settings like retail, transportation, and healthcare.