Zünd releases Cut Center 3.0 software suite

Zünd has added new functionality to its Cut Center production planning and job management software.

Zünd is introducing Version 3.0 of its comprehensive Zünd Cut Center – ZCC software suite, which is designed to offer additional and enhanced registration methods for even greater productivity, as well as an added, browser-based dashboard for remote access to all performance and production data.

The company has expanded its suite with new functionalities and another boost in performance and user-friendly operation. The new release includes a variety of intelligent workflow options. Additional registration methods are said to generate significant increases in overall productivity.

Version 3.0 now includes refined algorithms for capturing only those register marks essential for accurately determining position, skew and distortion. Consequently, the ICC camera targets only critical marks for capture, translating into productivity gains.

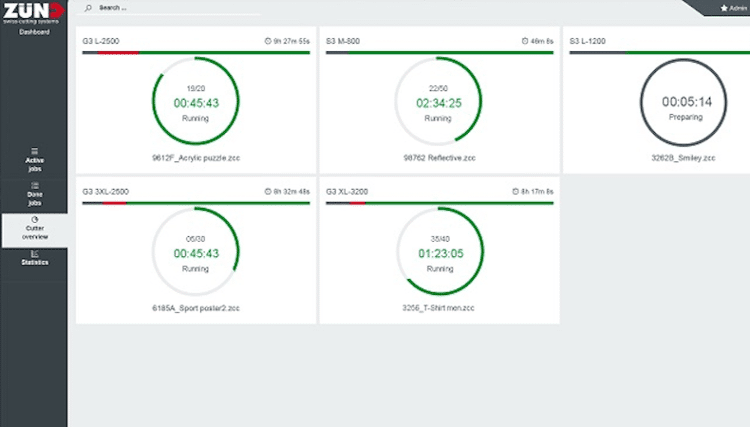

Dashboard is another highlight of the latest version of Zünd Cut Center. This new browser-based function visualises performance and productivity data of the Zünd cutters operating on the production floor.

Dashboard gives management and production staff easy, round-the-clock remote access to all relevant production data. Real-time job status can be viewed anytime, anywhere. Visualised statistics provide a clear, instantaneous overview of Zünd cutter productivity for user-definable time periods.

Quality and productvity

“Organisation and clarity are the be-all and end-all of smart production planning. That is exactly what Zünd's proven Cut Queue offers, with a tool palette that facilitates production planning and job management,” the manufacturer explains.

Cut Queue estimates production times and facilitates setup by visualising job contours. Many settings, such as overcut compensation and offsets for objects and cut paths, can either be handled automatically through hot folders or manually, at any time, via Cut Editor.

Hot folders automatically generate production-ready files from commonly used layout and CAD programs. This accelerates file prep and eliminates manual steps in job setup.

At the same time, the software also automatically optimises cut data for the shortest possible processing time by determining the optimal cut direction, cut sequence and cut path, closing open contours, smoothing curves, etc.

Cut Editor also provides such useful functions as crease-counter generation for high-quality creasing, powerful nesting features for maximum material yield, and a variety of routing features.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

Special Effects in DTF Will Make Your “Prints” More Memorable

The DTF market is expanding with new vendors and innovations like multi-head printers enabling diverse ink options (spot, neon). Decorative films offer streamlined special effects. Keypoint Intelligence tested metallic and glitter films, noting varied ease of use and wash durability. New technology using adhesive and foil directly promises further creative advancements in DTF.

SmartHub – Expectations, opportunities and why you should attend!

The SmartHub at Personalisation Experience 2025 in Berlin will showcase personalisation and smart production opportunities across industries like textiles. Featuring a Smart Factory Trail with brands like Inkcups and Trotec, and a conference with experts discussing AI, mass customisation, and profit strategies, it offers insights into reducing waste and boosting efficiency through digital methods. Panel sessions will explore growth, automation in textiles, and smart manufacturing.

How is AI revolutionising Large Format Print?

Nessan Clearly discusses how AI in print relies on data pattern matching, already enhancing software for large format providers. He predicts that this will result in increased AI integration in workflow planning, job queue management, colour correction, image upscaling, and predictive maintenance via sensors and vision systems, ultimately streamlining operations and offering greater flexibility.

One Ink for All? Exploring Pigment in Textile Printing

Digital textile printing faces complexity due to diverse substrates requiring specific inks. The industry seeks a universal ink, with pigment ink showing potential. While traditionally for natural fibres, advancements aim to broaden its application, simplify processes by reducing pre/post-treatment, and improve sustainability, though challenges like hand feel on garments remain.