Personalisation

Personalisation offers the consumer the opportunity to create products that are just that – personalised. That doesn’t always mean what you might think? Personalisation takes on many forms, from couture fashion to customised canvasses - there is a world of difference between both and many commercial opportunities in between.

The growth of personalised products is accelerating alongside the growth of ecommerce. In an on-demand world there are benefits for the consumer and the savvy entrepreneur.

Across the print space customised, personalised manufacturing offers an environmental and sustainable business model and its success is very much dependent on the technology and automation utilised for manufacture and fulfilment.

Examples include: Art, Canvasses, Wallpapers, Cushions, Lighting, Window Blinds, Window Graphics and Lightboxes.

In recent Printeriors exhibits we have showcased many applications, materials and technologies, many of which cross industry sectors:

Printing applications utilised include Roll to Roll, Dye Sublimation, Transfer Printing, Flatbed UV and Latex and others. Inks sets span Dye Sublimation, Latex, Pigment, UV and Reactive Inks across many applications and materials. Some examples of which are featured below:

The array of applications, products and commercial opportunities for personalisation is infinite. Technologies across all sectors are used, allowing convergence for the print community across market sectores.

The ecommerce boom has also boosted the personalisation business model, as software evolves for smart manufacturing and end-to-end fulfilment there are no limitations for entrepreneurial growth with in this sector.

The image below shows just some of the options for personalisation, in truth almost any surface can now be digitally printed leading to widespread democratisation for this marketplace. Crossing not just Interiors but every sector of the printing industry.

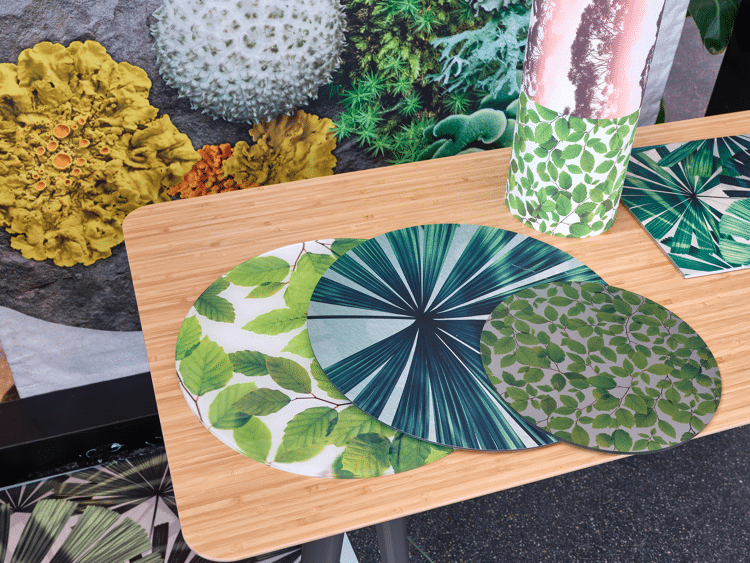

Technologies cross all ink sets. Below we can see personalised acrylic placemats each custom printed to showcase the different surface effects that can be achieved. Recent innovations in white inks have empowered the creativity within the sector further, pushing the boundaries of design and production. Also seen in the right-hand corner of this pic is a piece of UV printed wood, as flatbed technology evolves we are witnessing evermore functionality and the ability to build textured, printed surface effects at increasing print speeds. Samples were kindly supplied by Imageco using HP and others Mimaki technology.

The image below aims to give an indication of the multiple surface effects that can now be created using digital technologies. Showcasing wallcoverings from Canon printed using UV technology, textiles from Durst using dye sublimation onto rPET polyester fabrics from Premier Digital Textiles. Laminated mirrors using printed self-adhesive film from Drytac and personalised flooring kindly printed by MediaCo.

Topics

Recent news

Industry Insights, Design Trends and Disruptive Innovations for Interior Decoration

Debbie McKeegan shares key trends and innovations in the interior decoration industry taking place and demonstrated at recent European exhibitions in Germany and France. The interior decoration industry is adapting to challenges like overstock and supply chain disruptions by integrating digital and traditional methods, aiming for more agile and environmentally friendly solutions.

Bridging Design and Technology: The Story of Western Sensibility an interview with Kathryn Sanders

In this podcast episode, Debbie McKeegan interviews Kathryn Sanders, the CEO & founder of Western Sensibility, a US based company that merges interior design with digital printing technology. They discuss the origins of the business, its innovative services, and the importance of sustainability in the textile industry.

How to choose the right machine for indoor print

With interior print one of the stand-out growth areas of the industry in recent years, it is crucial printing companies select the right equipment to achieve the best quality results. Here, Rob Fletcher picks out some of the machines best suited to this work.

Resilience, Innovation and Heritage: The 100-Year Journey of the Standfast & Barracks

Renowned textile printing facility, Standfast & Barracks celebrates 100 years who are known for their expertise in rotary, flatbed and digital printing techniques. Debbie McKeegan looks at the history of the company and speaks to Lisa Montague, Managing Director about how they have adapted over the years and their future plans.