The latest trends in Circular Economy

Clare Taylor provides an update on what different countries around the world are doing in their governments to strive for a circular economy.

A couple of years ago I wrote about the circular economy and some new business models: about the need for innovation in the way design is approached and the way businesses and governments work in order to survive in a world with finite resources but seemingly infinite demand for them; the need to take a more regenerative approach, and a fairer one.

Now seems a good time to revisit it and see what’s happening now, as Earth Overshoot Day 2023 has just passed. This is the date when our demand for resources so far during the year goes beyond what the Earth can regenerate in that year. In investment terms, it’s when we stop living off the interest and start eating into the capital. In 1971 it was on 25 December; this year it was 2 August. So a good month to take stock.

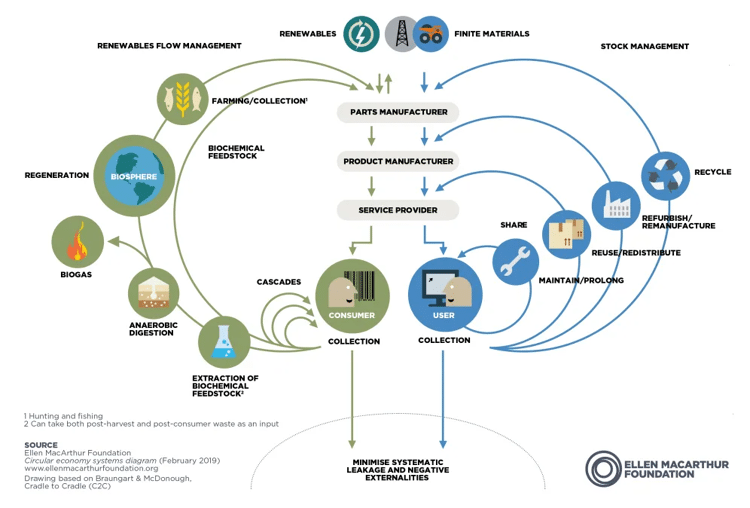

As a reminder, the aim of the circular economy is that nothing should go to waste, pollution should not be created and natural systems should be regenerated. It’s part of the answer to this overshoot.

Policy

There is a lot happening around the world. The EU have had a circular economy action plan and monitoring framework for a few years now, and this year have added some new indicators on resource efficiency and consumption, and new actions: European members of this industry should be aware that among the sectors they are focusing on are packaging, plastics and textiles. The UK have stated the intention to continue circular economy plans regardless of leaving the EU. The US embarked on their plans a little later, with much of their focus currently on recycling, but this year put a strategy out for comment on preventing plastic pollution and have plans to address electronics, food and organics. Australia is following a workplan to achieve a circular economy by 2030. Chile, China, Japan and many others are acting. The message is clear – this is a growing policy area, and we can expect to see further legislation and/or taxes coming to make it work, supplementing and joining up existing laws around the world to drive producers to design out single-use or unrecyclable products and to build markets for recycled materials.

Some good IT news is that, as part of all this, plans for right to repair legislation are moving forward globally, with implementation under way in some parts of the world and proposals moving forward in others. These policies, though varying in different places, are generally aimed at preventing sealed units that cannot be accessed for repair, stopping built-in obsolescence and ensuring availability of replacement parts and software upgrades (as applicable – they cover a wide range of consumer goods). This will help reduce both e-waste and demand for rare earth and conflict minerals, and should avoid the frustration and expense of having to replace equipment rather than carry out what should be simple repairs or upgrades.

Many businesses, especially the larger global companies, are also including the circular economy in the policies. This year saw the 10th anniversary of the Ellen MacArthur Foundation’s launch of the CE100 Programme, which was intended to bring together a ‘network of 100 leading companies globally to facilitate development and commitment to new circular economy projects’. This network now includes cities, states and academia as well as businesses, including several from our industry, and a circular economy community for smaller organisations.

Public procurement has been embracing the circular economy now for long enough that there are many case studies available, including one for street signs in Malmö where requirements within the tender request included reuse and recycling.

What this means for your business

Looking at your business and thinking about what you can be doing to improve the circularity of your business model – not just products - can help you be prepared for the future, and perhaps put you ahead of the game with customers, as with the winner of the Malmö tender. Movement towards ‘goods as a service’ is growing: the producer manages, maintains, refurbishes, upgrades or replaces their products as needed, sometimes retaining ownership, as part of a contracted service. This clearly won’t work for everything, but for such things as display units and signs, clever design can allow for elements to be updated while keeping the main body, and some clothing companies are already designing and manufacturing clothes in a way that enables them to take them back for recycling.

For businesses wanting to improve circularity, or at least take a lifecycle approach to their products, there is an ISO standard designed to work with an ISO 14001 management system but which fits equally well into ISO 9001. ISO 14006:2020 Environmental management systems — Guidelines for incorporating ecodesign is a guide to help a business work through every stage, from purchasing materials, through design, manufacturing, delivery, considerations for during use, and end-of-life treatment.

For anyone wanting to learn more about the circular economy or look for ideas and case studies, www.ellenmacarthurfoundation.org is an excellent place to start.

Header image credit: Ellen MacArthur

Topics

Recent news

A revised look at sustainability in wide format print

Sustainability is crucial for wide-format print, moving beyond marketing to an imperative driven by brands and regulations. Common "eco" claims often mask complexities; true sustainability demands carbon reduction as a core principle. Life Cycle Assessment (LCA) offers data-driven insights for genuine environmental improvement, as demonstrated by UFABRIK's transparent approach.

Empowering the Print Community – Insights from Suzi Ward, MD of FESPA UK

In this podcast episode, Debbie McKeegan interviews Suzi Ward, the Managing Director of Fespa UK, discussing the evolution of the association, its role in supporting the print industry, and the importance of community engagement.

.png?width=550)

The European Union is driving massive sustainability change

The EU's ambitious Green Deal, aiming for climate neutrality by 2050, drives significant sustainability changes. Businesses worldwide, especially printers, must adapt to complex EU legislation. Compliance creates challenges but also new opportunities in areas like packaging and signage.

What are the benefits of print businesses committing to a Net Zero Carbon emissions target?

We speak to Robert Connell, Senior Commercial Sustainability Manager at ClimatePartner who who offer solutions along the net zero cycle to support business’s effort in corporate climate action. In this discussion we discuss the importance and the process and benefits of businesses committing to a Net Zero Carbon emissions target.