Future-Fit: taking sustainability beyond benchmarking

We speak to Geoff Kendall, co-founder and CEO of charity Future-Fit Foundation, about how printers can ensure their company’s sustainability is more than superficial.

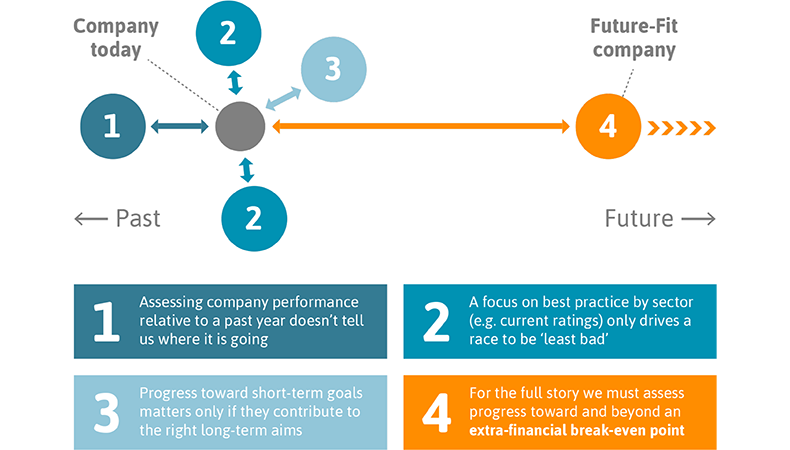

“Benchmarking means you’re measuring yourself against something,” says Future-Fit boss Geoff Kendall. "For example, you might benchmark yourself against your peers, but that’s a short-sighted view when transforming our economy towards a fair and regenerative future for everybody. We don’t need to just benchmark against the unsustainable status quo, we need to benchmark against the future we want.”

“The term can be counterproductive, so perhaps we came up with the wrong word when we decided to call our methodology the Future-Fit Business Benchmark,” he says candidly.

With a PhD in artificial intelligence and a career that has spanned software, communications and sustainability, Geoff has thought about the issues around long-term social and environmental health a little deeper than most. Around 10 years ago, he realised the way the corporate world was approaching sustainability was wrong.

“Traditionally, when companies looked at sustainability, there were a wide range of ratings and rankings, such as FTSE4Good, Corporate Nights Global 100 and Dow Jones Sustainability index. Those were what companies looked at and the ratings by which they judged themselves, which was an understandable approach,” Geoff says.

Understanding your organisation’s relationship to society and the broader environment, and then proactively figuring out how to live within our means, builds resilience into your business

“The problem is, all those ratings and rankings look at relative performance within industries. They look at who the best printing company is, or who the best oil company is, and the scoring is based on that. But that means you end up with rankings that are distorted: you might have an oil company that is rated as 90% sustainable, but that’s just because it is better than most of the other oil companies.

“That doesn’t send the right signals to the management of those companies or to their investors about whether that company is actually doing enough.”

Start with the science

Instead of looking at current best practice, Geoff decided to create an approach that is based on what is really needed for a sustainable planet.

“I said, let’s start with the science and then work backwards to find out what that means for any company and what they should do. All of the information I needed to do that was available, it just wasn’t in the form that an average CEO could find and work with,” he says.

“Future-Fit Business was started as a non-profit organisation in 2013 to really take all of the great system science that was already out there – which looks at the patterns and relationships of how different social, environmental and sustainability factors interact – and translate it into a form that companies could use.

“That became what is now known as the Future-Fit Business Benchmark and that draws the line in the sand that any company needs to reach to ensure it is not undermining progress to the future we need. It also articulates all the positive contributions that a company can have that actually accelerate that progress. And it provides a set of metrics to help you understand how far away you are from that point, so you can start to take better decisions in pursuit of becoming what we would call a Future-Fit business.”

Becoming Future-Fit

So how can a company go about becoming a Future-Fit business? As a non-profit organisation, all the resources are free and online.

“If you go to FutureFitBusiness.org, you can find all of our materials. What we suggest is that businesses start with what we call a health check, where they look through various parts of the benchmark. This will help them understand what are the highest priorities that they really need an answer to. From there, it will then offer deep-dive guidance on each of those high priorities,” Geoff says.

“It might feel overwhelming to look all the environmental and social issues in the world and think: what do we do with this? Often people are paralysed by that. So, the approach we provide involves guidance on all the issues affecting business, but with a lens to say: here are the four or five things, based on the kind of business you’re in, that you really need to pay closest attention to.

“And we also have FutureFit.community, our online community with loads of resources, including recorded videos featuring training, webinars, and so on, where people can get started.”

Now more than ever

The goal of becoming ‘Future-Fit’, Geoff says, is more pressing than ever, and as relevant to the print trade as it is in many other sectors.

“As a society, we’ve thought about sustainability for many years as a ‘nice to have’: something you should do because it’s the right thing to do – but of course things like that always get sidelined when there are other pressures such as interest rate increases or supply chain interruptions. But understanding your organisation’s relationship to society and the broader environment, and then proactively figuring out how to live within our means, builds resilience into your business,” Geoff says.

Any printer who can proactively say that all their products are safe for the environment gets that all-important procurement tick in the box

“An obvious example right now is any business that has already moved to renewable energy, and which has already switched to electric cars, is far less affected by the challenges coming with the oil shock influenced by the war in Ukraine. Another example would be using locally produced supplies. To the degree you can achieve that, by doing this you are insulating yourself from transport costs and international supply chain disruptions.

“In terms of the print industry, the obvious environmental issue is waste and whether things can be recycled. If everything can be made recyclable, it not only improves a printer’s environmental impact, but it also impacts their desirability to corporate customers. I know of organisations now who won’t even look at ordering business cards or brochures if they’re not printed on recycled paper, and they also expect those products to themselves be recyclable.

“I think more of that is coming. There is more pressure on companies, and on local government too, to procure well for the good of the planet. If printers can get ahead of the game on this stuff and use inks that are biodegradable and materials that are recyclable via current civil infrastructure, that is a big advantage. Any printer who can proactively say that all their products are safe for the environment gets that all-important procurement tick in the box.”

Outside the box

Geoff believes printers can also play a leading role in making packaging more environmentally friendly.

“Often printing is for things like labels on bottles. In that case, it is really important because the label can affect whether the bottle itself is recyclable or not. It’s infuriating to have plastic tubs or bottles, which are perfectly reusable or recyclable except you can’t take the label off,” Geoff says.

“There are a few cases like that where a little more conscious thought in the design and how you can separate these things at end of life, would be beneficial. And, again, this is something that the big brands really gravitate towards. Sustainability is really hard, and companies will choose you if you can provide them.”

No matter how responsibly you are manufacturing, the amount you are producing will have a big impact

Finally, one consideration that all of us should pay attention to, whether as a manufacturer or consumer, is the sheer volume of products in our lives.

“One of our massive challenges that is often unspoken is the amount of through-put in the economy – the amount of stuff that we are taking out of the environment, and then the amount of stuff we are dumping back into it. No matter how responsibly you are manufacturing, the amount you are producing will have a big impact,” Geoff says.

“Fast fashion is a good example. Companies might say they are only using organic cotton and safe dyes, and people in the supply chain are paid a fair wage, but they’re missing the point slightly in that their marketing and business model is trying to convince customers that they need a new garment every few weeks. You’ll never get down to zero impact when making an item, so the number of items you make is ever more important.

“So I think we need to move back to more localised and on-demand service requirements. The days of really big printers running the presses 24 hours a day, seven days a week and shipping everywhere in the world are gone – I think those are the businesses that may really struggle.”

Become a FESPA member to continue reading

To read more and access exclusive content on the Club FESPA portal, please contact your Local Association. If you are not a current member, please enquire here. If there is no FESPA Association in your country, you can join FESPA Direct. Once you become a FESPA member, you can gain access to the Club FESPA Portal.

Topics

Recent news

Regulation guidance: Corporate Sustainability Reporting Directive

The Corporate Sustainability Reporting Directive (CSRD) is now in effect, but with further changes on the horizon, what does it mean for printers? Sustainability consultant Rachel England outlines everything you need to know and talks to Apigraf about how your business may be affected.

Web-to-print design: Canva versus Kittl

We look at popular design packages Canva and Kittl to determine how they compare regarding graphic design and print on demand.

FESPA in South Africa: the print skills to thrive

Printing SA’s Career Day inspired young Cape Town learners to explore printing and packaging careers.

The rise of Chinese printers

Chinese printing companies are on the rise, and have their eyes set on the UK and EU marketplace. Some have made an instant impact; others are running into issues with maintenance and language barriers. What does the future hold for Chinese printing firms, and how can you navigate working with them?