The case for UV LED on performance and durability

EFI on the environmental benefits and energy usage of UV LED.

UV LED technology has better performance and durability compared to latex. UV inks are formulated to print directly on to a wide range of flexible and rigid substrates (for example PVC, wood, foamcore, coroplast, aluminum, vinyl, polycarbonate, as well as a growing number of environmentally friendly and recyclable materials) and do not require any special coatings, which saves printers both time and money.

While latex printing has recently evolved to produce direct-to-board/flatbed applications, the process for producing rigid work on many latex printers out in the field may involve mounting media to a board, which adds time and cost to the process and may be more difficult to recycle.

The combination of LED technology and EFI innovative inks help reduce waste, lower energy use and satisfy more customer demands

Recently, EFI roll-to-roll UV LED printers have earned a Type II certification for wallcoverings based on The Wallcovering Association W-101 and ASTM F793 standards. Type II certification is an indicator for quality, safety, and durability of wallcoverings and, unlike other Type II certifications for digital inkjet printers, EFI’s new certification covers wallcoverings produced without lamination or coating.

What are the environmental benefits of latex vs UV printing on rigid materials?

With decreased power consumption, no bulb replacement and less material waste, EFI UV LED technology provides sustainable advantages. It eliminates the need for high-power lamps to ensure proper image adhesion and additional heat to evaporate water waste from printed images. There’s also no warm-up time with instant on/off LED lamps, so printers use less energy while increasing uptime and productivity. It also eliminates wasted output associated with uneven curing or colour shifts that often result from mercury vapour bulb degradation. In addition, EFI cool cure UV LED technology allows printers to print with photo quality on a wide variety of heat-sensitive substrates, including recycled materials.

EFI UV LED inks contain less than 0.03% volatile organic compounds and are void of heavy metals. They also contain up to 50% monomers and oligomers that are naturally derived from renewable resources, such as plants and biomass.

The difference in energy usage is a result of the power needed for drying or curing prints after they come off of the printer

Printers’ profitability and customer satisfaction hinge on the number of substrates they can print without creating excessive waste. The combination of LED technology and EFI innovative inks help reduce waste, lower energy use and satisfy more customer demands.

What are the environmental disadvantages of latex vs UV printing?

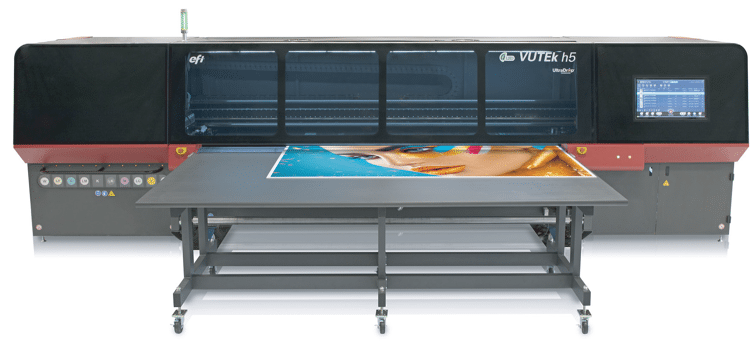

UV LED uses considerably less energy usage compared with latex. The difference in energy usage is a result of the power needed for drying or curing prints after they come off of the printer. A Fogra study comparing UV LED with other technologies noted that the heating difference accounts for up to 82% less energy used with UV LED on EFI VUTEk printers. For those who report that the odour of UV ink is unpleasant compared with latex, genuine EFI inks are formulated from raw materials that produce little to no odour when fully cured.

Become a FESPA member to continue reading

To read more and access exclusive content on the Club FESPA portal, please contact your Local Association. If you are not a current member, please enquire here. If there is no FESPA Association in your country, you can join FESPA Direct. Once you become a FESPA member, you can gain access to the Club FESPA Portal.

Recent news

Regulation guidance: Corporate Sustainability Reporting Directive

The Corporate Sustainability Reporting Directive (CSRD) is now in effect, but with further changes on the horizon, what does it mean for printers? Sustainability consultant Rachel England outlines everything you need to know and talks to Apigraf about how your business may be affected.

Web-to-print design: Canva versus Kittl

We look at popular design packages Canva and Kittl to determine how they compare regarding graphic design and print on demand.

FESPA in South Africa: the print skills to thrive

Printing SA’s Career Day inspired young Cape Town learners to explore printing and packaging careers.

The rise of Chinese printers

Chinese printing companies are on the rise, and have their eyes set on the UK and EU marketplace. Some have made an instant impact; others are running into issues with maintenance and language barriers. What does the future hold for Chinese printing firms, and how can you navigate working with them?