How to select the right RIP

.jpg?width=750)

What to look for when selecting RIP software

One of the benefits of visiting FESPA’s Global Print Expo in Berlin will be to meet one of the many Raster Image Processor (RIP) software developers offering a solution to maximise the efficiency of your digital press or screen preparation system.

There are plenty of choices available in the market; whether Caldera, Onyx Thrive, Efi XF, ColorGATE, Ergosoft, Shiraz, Digital Factory, Wasatch or Esko to power your inkjet production press or cutting device. In addition, you may require Accurip, Harlequin, GrafcoAST XerioRIP and GMG for film/CTS production, to name a few. The choices may be reduced if you’re looking to install a new printer as you’ll probably be recommended a bundled deal. However, it’s worth taking some time to consider your needs, both now and over the expected useful life of the printer it’ll be driving.

Colormetric validation

The key decisions may be linked to the ability to create custom ICC profiles to ensure that you can characterise a range of media or the need to print and measure a patch target, such as using the Fogra LFP Media Wedge. This functionality would ensure that you make colour measurement a priority. If you’re ripping files for a proofing workflow you’ll be printing on Fogra certified proofing paper and wanting to print a Fogra Media Wedge colour target for colorimetric validation.

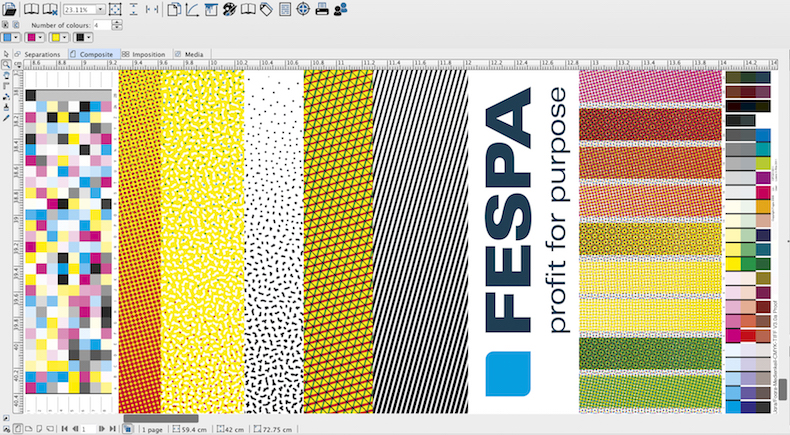

Products such as the Efi Fiery XF RIP can be enhanced with additional modules to include OneBit for ripped halftone proofs to ensure that you represent the final production output appearance in a proof that will include halftoning choices. There are occasions when, for example, proofing for screen printing, that this level of sophistication will reveal resolution issues that may otherwise be missed and be a cause for dispute. In many use cases for smaller print companies these benefits may not fit their customer demands, and despite their benefits to process, control can’t be justified.

Fig 1. Fiery XF RIP from Efi. This image shows the advanced colour tools option that provides a wide array of methods of checking and optimising ICC profiles including a useful ΔE tolerance visualisation.

Accommodating AM and FM screening choices

If you are planning to run film separations through an Epson inkjet printer at a reasonable price you might consider a solution like Accurip which is intended for quality inkjet films with a range of AM (amplitude modulated, conventional) and FM (frequency modulated, stochastic) screening choices. When bundled with Separation Studio, also from Freehand Graphics, a cost-effective spot colour separation solution for garment decorators emerges.

However, if you’re interested in the benefits of mixing AM and FM screening for more avoidance in film output it is essential that you include the Harlequin RIP from Global Graphics and GrafcoAST’s XerioRip 4 products in your review. These packages both offer the hybrid screening option and advanced TVI (Tonal Value Increase or Dot Gain) correction for linearisation. While most film RIPs facilitate a reasonable degree of customisation and calibration using a transmission densitometer, these two solutions are more agile for experienced users.

XerioRIP provides the ability to mix AM and FM screening within the same colour which in the right hands leads to exceptional results in screen print between 90-120lpi. The GrafcoAST software also allows you to save a high res ripped preview to PDF that you can use to either output via a proofer or send to email for sign off. When linked to the Xerio SEP spot colour separation software presents a formidable tool set for ambitious screen printers.

Fig 2. XerioRIP from GrafcoAST. Linearisation tools are essential to adjust for TVI (dot gain) in stencil making, whether film or CTS and on press. Correct reproductions cannot be achieved without this process being completed using the right measurement devices.

Many wide format RIP’s present equivalent features in speed, colour management, tiling, nesting and cutter path interpretation. This is probably not that surprising as many are built around a narrow field of postscript interperators including Global Graphics Jaws or Adobe’s PDF APPE print engine. You may also be considering automated workflows from web-to-print front ends.

Priorities and future-proofing

So, the questions is how much control is of value to your production needs? There is no doubt that when you have customers with clear expectations of the colour reproduction tolerances or you wish to simplify the printing process through calibration, the ROI can be very high. It really depends on your skills and appetite to get your hands dirty.

Some good advice would be to think through your list of workflow and production priorities before making any purchasing decisions. Even the same vendor will offer a range of software solutions, from a cut down entry level to the full ‘bells and whistles’ system. Make sure you choose a RIP solution that helps you now, but also consider one that can be upgraded to meet the requirements you’ll have as your business grows.

Become a FESPA member to continue reading

To read more and access exclusive content on the Club FESPA portal, please contact your Local Association. If you are not a current member, please enquire here. If there is no FESPA Association in your country, you can join FESPA Direct. Once you become a FESPA member, you can gain access to the Club FESPA Portal.

Topics

Recent news

Regulation guidance: Corporate Sustainability Reporting Directive

The Corporate Sustainability Reporting Directive (CSRD) is now in effect, but with further changes on the horizon, what does it mean for printers? Sustainability consultant Rachel England outlines everything you need to know and talks to Apigraf about how your business may be affected.

Web-to-print design: Canva versus Kittl

We look at popular design packages Canva and Kittl to determine how they compare regarding graphic design and print on demand.

FESPA in South Africa: the print skills to thrive

Printing SA’s Career Day inspired young Cape Town learners to explore printing and packaging careers.

The rise of Chinese printers

Chinese printing companies are on the rise, and have their eyes set on the UK and EU marketplace. Some have made an instant impact; others are running into issues with maintenance and language barriers. What does the future hold for Chinese printing firms, and how can you navigate working with them?