FESPA Award winner: Tobex’s roll-to-roll textile installation

Digital on-demand printing company and small-scale sewing factory Tobex won a FESPA bronze award in the roll-to-roll printed textiles category.

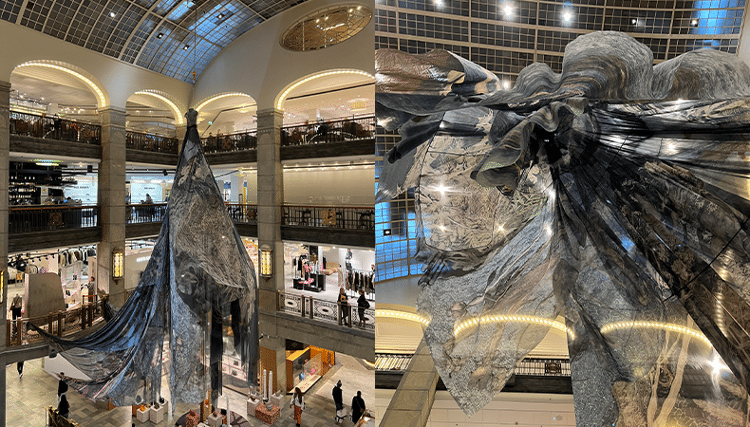

This giant sculptural ‘Flora Dress’ by artist/scenographer Martin Bergström was created for display in the heart of Sweden's most famous department store in Stockholm. The process entailed printing 135 metres of inkjet-printed polyester voile, which was installed to hang from the ceiling cascading above people’s heads. The project was printed using dye sublimation on a Mimaki 320 digital printer using Mexar ink. We spoke to Anne-Lie Hummel Högblom, CEO of Tobex.

What was the brief, and what were you attempting to achieve with the work?

We´ve been working with this artist for years, collaborating and interpreting his ideas and trying to fulfil his artistic intentions.

How long did you have to complete the project?

Any project always starts with a conversation that goes on for a while. We also have to factor in several test prints to make changes that might be needed to improve the depth of the colours and make them come alive.

What are the benefits of the material choices that you made?

The material was a transparent polyester voile that is very effective if you can apply the right print to it. We did direct/dispersion print and worked a fair amount on the ink intensity. This was mostly manual work, experimenting in getting the right shadows and depths to be seen in the transparent print. We printed on a rebuilt Mimaki 320cm wide format printer.

What were the key challenges involved in the project relating to technology, materials, installation, design, sustainability, etc?

The material can only take a certain amount of ink and making colours look bright and sharp and standing out from each other is a challenge. The colours can easily bleed too much and look dull if you take them down too much. To create a dramatic effect is quite a challenge on such a thin material with direct sublimation.

How did you overcome those challenges?

Manually working with different fields of the print file and simply testing different approaches.

How many people were involved in the project?

There were three people involved in total.

What’s your favourite aspect of the product?

The beautiful result. And working conceptually.

How sustainable were your processes?

Our processes were very sustainable, since the only ink consumed is that printed on the fabric and the only energy the heat to fix it. The ink is a water-based sublimation ink from Mexar.

What does winning a FESPA award mean to you?

It is an important recognition: it gives us status among customer and suppliers as a high-end producer. Even though we have won a lot of FESPA awards over the years, it is still such a honour to be recognised for our hard work.

Become a FESPA member to continue reading

To read more and access exclusive content on the Club FESPA portal, please contact your Local Association. If you are not a current member, please enquire here. If there is no FESPA Association in your country, you can join FESPA Direct. Once you become a FESPA member, you can gain access to the Club FESPA Portal.

Topics

Recent news

The personal touch: visit Personalisation Experience’s SmartHub Conference 2025

Join the SmartHub Conference at Personalisation Experience next month to stay ahead of the latest tech and trends.

How to build brand trust using customer reviews

Reviews can benefit or damage your business’s reputation. From spreading the word to social proof, here is why reviews matter and what you can do to manage your customer reviews to improve your brand’s reputation.

Regulation guidance: Extended Producer Responsibility

Extended Producer Responsibility (EPR) is now in effect. What does it mean for those in the print industry? Sustainability consultant Rachel England outlines everything you need to know.

How to maximise the automation of your production workflow

Workflow automation has evolved beyond basic file prep, now encompassing job submission, prepress, and postpress. Printers automate to boost productivity, cut waste, and address skill shortages. Implementing tailored automation, from RIPs to MIS, optimises throughput and profitability, minimising human intervention.