It´s All About Data

In order to be a successful printer you need to have the right equipment. Wrong. Today, data and data processing have become the most valuable assets in the printing industry. Sonja Angerer shares why, and how this affects business models.

In the past, when printers would have an open house style event they would send invites that would read “come and see our new printer”. During the launch of a new product there would be press releases, speeches, food and drinks. However, it is unlikely that the same level of pride and joy is applied when a new Digital Frontend (DFE) and workflow solution has been installed.

Historically, evolving computing power and the rapid digitalisation of the graphic industry, created the foundation for digital print to become the dominating technology that it is today.

Digital print is most useful if it:

- can offer something that analogue print cannot (personalisation, Variable Data)

- can offer something better / more efficient than analogue print (small run-length, multi-color print).

- transactional print

- coding and marking.

Today, the economy is very dependent on the internet. Large amounts of data are available to brands and corporations. End consumers have become accustomed to a more personalized form of communications and individualised goods. Therefore, brand owners looking to the future are eager to incorporate digital print´s unique ability to provide both.

Although Variable Data Printing (VDP) has been around for a while, this might be the moment the technology really becomes mainstream.

Caption: Calls Software pdfaPilot 10 already supports latest ISO Standards PDF/X-6 and PDF/VT-3. Image credit: Callas Software

Caption: Calls Software pdfaPilot 10 already supports latest ISO Standards PDF/X-6 and PDF/VT-3. Image credit: Callas Software

What is Variable Data Printing?

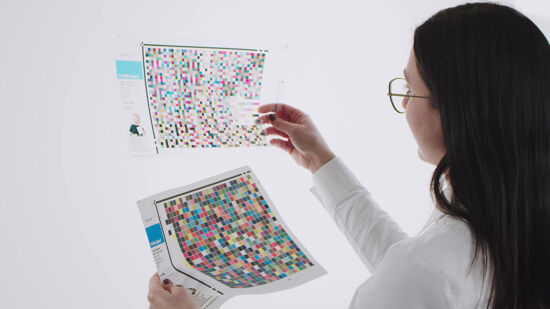

Today many printers are unhappy about the production run-length becoming more granular. Small jobs require nearly the same amount of time for ripping and printer set-up as the large jobs, but at a much smaller revenue. Alternatively, Variable Data Printing has a long run-length, even if every single page, board or item is quite different from another.

Nowadays, VDP is no longer limited to mailings and POS-applications. Personalised textile and home decoration items and one-of-a-kind packaging will become more important as retail moves to online-based business models in the next few years.

In the future, it is likely that a print application or product will be designed only once and combined with a data base to implement the right copy, logo and pictures for each item. The Digital Frontend (DFE) rips each unique design “on the fly”, filling the template with variable data as it goes. While this minimizes printer set-up time, very high data processing speed becomes imperative to ensure the printing machine can run at full speed.

Caption: Chili publisher Version 6 Variable Data Software. Image credit: Chili Publish.

Caption: Chili publisher Version 6 Variable Data Software. Image credit: Chili Publish.

How is Receiving VDP Files Different from Other Customer Data?

During the early years of Digital Printing, printers often had to put up with “open” data format, e.g. Adobe InDesign files. Today, PDF delivery has become the norm. There are many different versions of PDFs, with PDF/X-6 the latest recommendation for receiving customer data for print. PDF/VT-3 was introduced in late 2020, it was based on PDF X-6 and has been designed for VDP specifically. Experts are expecting it to replace today´s PDF/VT-1 standard and many older file formats like AFP, IJPDS and PPML. The latter mainly grandfathered in or adapted from direct mailing applications.

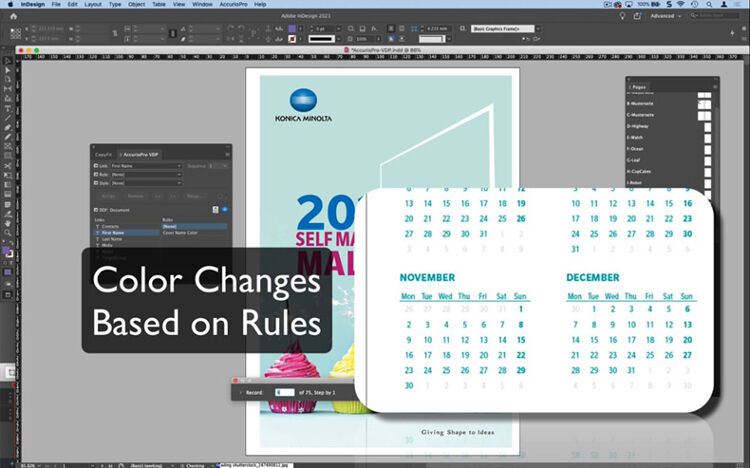

There are a couple of different options to create designs with VDP functionality, including Dynamic VDP from Esko, AccurioPro Variable Data from Konica Minolta as well as the Chili Publish Suite and EFI Fiery VDP solutions.

The quality of customer´s files have always been an issue in the printing industry. But with VDP, even very small delays for each unique design will contribute to a revenue-eating problem over a few thousand pages or items. As print production is no longer commanding Centre Stage at designer education anymore, it’s even more important for printers to educate their customers about VDP file delivery.

Data for Automated Finishing

In the PDF/VT format a framework for metadata regarding delivery, page split between presses and other direct mail related automatization task is already included. It can be used in appropriate workflows. However, PDF Processing Steps (ISO 19593-1) is more relevant for Wide Format printing printers.

It is supposed to standardize the implementation of cutting and creasing lines and foiling. Removing misleading naming and installing PDF layers indicates certain finishing steps. The standard, published in 2018, has already been taken up by companies such as Callas, Esko and Global Graphics.

Summary: What Can Printers Do to Adapt to the New World of Data?

With data handling and automated workflows becoming increasingly more important for the profitability of printers, it seems advisable to direct investments into this area. However, it’s just as important to educate employees and customers about data handling, since in VDP any data that’s less than perfect will effect your business even more than usual.

Topics

Interested in joining our community?

Enquire today about joining your local FESPA Association or FESPA Direct

Recent news

What are the opportunities for printers regarding backlit displays and window graphics?

Nessan Cleary describes the various opportunities for printers regarding window graphics. There is a wide range of materials and lighting options available.

What is the difference between labels and packaging regarding narrow web printing?

Nessan Cleary shares how labelling has always been distinct from packaging but increasingly lines are becoming blurred between them.