How to design for a circular economy in a linear world

Laurel Brunner explains the challenges for businesses to prioritise circular economy when economies have evolved to be linear. Laurel shares examples of different businesses who are designing products that can suppor the circular economy. These include The Ellen MacArthur Foundation, DS Smith and Vilsund Blue A/S.

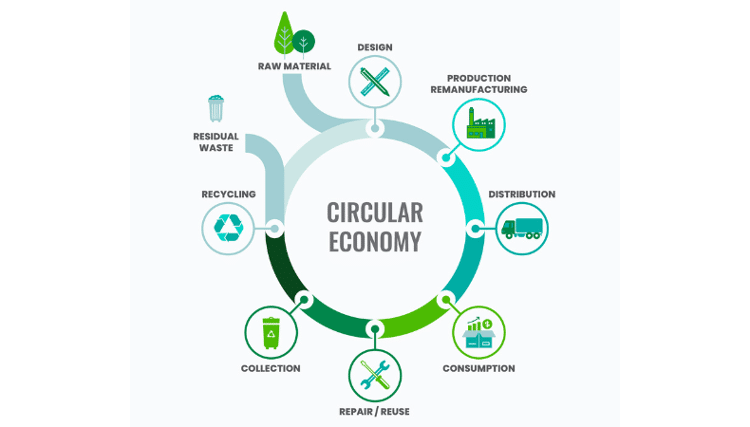

There has been many discussions surrounding circularity as a means of mitigating climate change impacts for quite some time now. The truth is that it is very hard to think in a circular way when economies have evolved to be linear. Just trying to write that down is hard. Getting your head around it is equally so. A circular economy is based on the idea that what you produce should generate no waste: once it reaches end-of-life, it should be possible to use its components as raw materials for something else. A linear economy basically comes down to never looking over your shoulder at what’s been left behind, mostly mess and waste. The take, make, waste concept is not balanced with what we need to do to mitigate climate change.

But designing products so that they support the circular economy model is difficult. The Ellen MacArthur Foundation has been working on principals to make it less hard and there are now several implementations of these principals coming into the market. One of these comes from a print industry practitioner. DS Smith, an international leader in sustainable and fibre-based packaging solutions, has developed a set of Circular Design Metrics. Even if you aren’t vaguely interested in packaging production, the metrics are useful because they provide a means of measuring what matters in a circular economic model instead of a linear one. DS Smith uses its metrics to measure the impact of its projects such as replacing plastic pallets for canned products with corrugated cardboard. To achieve this the company has been working with Vilsund Blue A/S Denmark’s biggest industrial producer of seafood and shellfish. This company has three industrial sites and employs some seventy people in Denmark. These employees cook, pack, and distribute up to 250 tonnes of fresh shellfish, every day.

The two organisations tasked their designers to come up with a way of eliminating plastic. They used the DS Smith Circular Design Metrics (CDM) tool to compare the circularity of alternative new packaging designs. The designs were then rated across eight indicators, including supply chain optimisation, design for reuse, carbon footprint and material utilisation. The CDM tool indicated the circularity of a design for various packaging systems suitable for customer requirements.

With its new fibre-based packaging, Vilsund Blue A/S has substantially increased the number of canned units on individual pallets. Capacity has risen from 1,800 tins of fish per pallet to 2,700. The goods can be more efficiently stacked and stored and are more compact on retail shelves. Gains such as this make a considerable difference to the organisation’s carbon footprint, not least in the reduction in emissions associated with transportation and storage. This joint project is a great example of how innovation drives progress but it also demonstrates the importance of having the right tools for the job.

Source information: This article was produced by the Verdigris Project, an industry initiative intended to raise awareness of print’s positive environmental impact. This weekly commentary helps printing companies keep up to date with environmental standards, and how environmentally friendly business management can help improve their bottom lines. Verdigris is supported by the following companies: Agfa Graphics, EFI, Fespa, Fujifilm, HP, Kodak, Miraclon, RicohSplash PR, Unity Publishing and Xeikon.

Recent news

A revised look at sustainability in wide format print

Sustainability is crucial for wide-format print, moving beyond marketing to an imperative driven by brands and regulations. Common "eco" claims often mask complexities; true sustainability demands carbon reduction as a core principle. Life Cycle Assessment (LCA) offers data-driven insights for genuine environmental improvement, as demonstrated by UFABRIK's transparent approach.

Empowering the Print Community – Insights from Suzi Ward, MD of FESPA UK

In this podcast episode, Debbie McKeegan interviews Suzi Ward, the Managing Director of Fespa UK, discussing the evolution of the association, its role in supporting the print industry, and the importance of community engagement.

.png?width=550)

The European Union is driving massive sustainability change

The EU's ambitious Green Deal, aiming for climate neutrality by 2050, drives significant sustainability changes. Businesses worldwide, especially printers, must adapt to complex EU legislation. Compliance creates challenges but also new opportunities in areas like packaging and signage.

What are the benefits of print businesses committing to a Net Zero Carbon emissions target?

We speak to Robert Connell, Senior Commercial Sustainability Manager at ClimatePartner who who offer solutions along the net zero cycle to support business’s effort in corporate climate action. In this discussion we discuss the importance and the process and benefits of businesses committing to a Net Zero Carbon emissions target.