Points of sustainability progress

Laurel Brunner shares progress that has been made in sustainability across the print sector with a particular look at ISO standards and recycling.

Since this blog started we have published over 500 articles talking about sustainability in the graphic arts. The goal is still to raise awareness of the industry’s environmental impact and to encourage all players in print media supply chains to take sustainability seriously. Only with the engagement of all players at an individual as well as at a corporate level will a difference be made. It seemed like a thankless and uphill task at the time, and it has been. But the signs are looking good.

So what progress have we made with this project? Perhaps the most important benchmark is the work we’re involved in via standards organisations and printing federations. The International Standards Organisation’s (ISO) technical committee for graphic technology has been extremely active for many years across a range of subject areas, from PDF/X to process control for various printing methods. Over the last few decades we have seen massive progress in standards relating to file handling and colour quality control. Overall the printing and publishing industries are far more efficient than they were thirty years ago. For the most part the work has been about improving data management and facilitating workflow automation, both of which are central to profitability. They cut inefficiencies, but these same efforts also cut waste to support environmental as well as commercial sustainability.

In 2009 an ISO TC130 working group dedicated to standards relating to the environmental impact of print was formed. This group has developed numerous ISO documents to help make print more sustainable, not least environmentally. Over the years we’ve fought many battles to get these documents through the consensus process that is the foundation of ISO work. Vested interests have worked hard to block sustainability in the industry and to do whatever it takes to avoid investing in systems that will facilitate improved recycling processes. But consensus has prevailed eventually.

Recycling remains the most difficult area to standardise because doing it efficiently depends on common sorting and processing models. That in turn depends on consumer motivations and having the right local services available. Some countries, such as Sweden, are amazing and others, such as the UK, are a mess. What we do know is that evolving printing technologies will require much more nuanced sorting and processing of printed matter, if present rates of successful recycling are to be maintained. This will take concerted pressure on pulp and paper plants to upgrade their facilities so that deinking processes work for all forms of print. We’ve taken some very minor steps to make this possible, but in the end it is up to the paper industry to take care of its own longterm interests. There’s not a lot that we can do to persuade the old fogeys still pulling the strings, but perhaps newer, younger generations of players will have the courage to embrace change. The industry and the planet depend on it.

Source information: This article was produced by the Verdigris Project, an industry initiative intended to raise awareness of print’s positive environmental impact. This weekly commentary helps printing companies keep up to date with environmental standards, and how environmentally friendly business management can help improve their bottom lines. Verdigris is supported by the following companies: Agfa Graphics, EFI, Fespa, Fujifilm, HP, Kodak, Miraclon, RicohSplash PR, Unity Publishing and Xeikon.

Topics

Recent news

Green Printing: how Sustainability drives business success

Nessan Cleary shares sustainable printing benefits businesses and the environment. Auditing suppliers and using eco-friendly materials are crucial. Optimising production with energy-efficient equipment and minimising waste reduces costs. Proper waste disposal and premises efficiency further lower the carbon footprint. Staff training and customer recycling solutions complete the sustainable approach.

Sustainability and keeping the faith

Laurel Brunner discusses how the printing industry has drastically reduced its environmental impact through technological advances, despite lingering perceptions of paper waste. While consumer habits pose a challenge, the industry continues to pursue greener practices.

Kyocera wins Anthem Award for Sustainability, Environment and Climate

Laurel Brunner shares how Kyocera, a Japanese manufacturer of digital printing system was awarded a silver award for its green skills report on "A Green Edge: Green Skills for the Future".

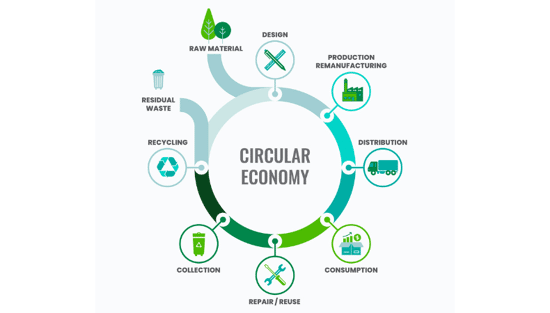

How to design for a circular economy in a linear world

Laurel Brunner explains the challenges for businesses to prioritise circular economy when economies have evolved to be linear. Laurel shares examples of different businesses who are designing products that can suppor the circular economy. These include The Ellen MacArthur Foundation, DS Smith and Vilsund Blue A/S.