Greener chemistry for textile & leather supply chains

John Murphy, Technical Director Europe from Hohenstein shares how OEKO-TEX® ECO PASSPORT is a credible proof of sustainable textile and leather chemicals that affect global consumers, manufacturers, brands, and retailers.

Responsible textile and leather products start with more environmentally friendly production inputs. For trusted proof of safer textile and leather chemicals, more and more brands and manufacturers are leveraging OEKO-TEX® ECO PASSPORT, which recently reached the landmark 13,000 certified chemical products. As a part of the modular OEKO-TEX® system, ECO PASSPORT is an effective tool to minimize the industry's harmful impact on workers, consumers, and the environment.

OEKO-TEX®: proactive action for a sustainable future

For more than three decades, OEKO-TEX® has stood for transparency along the international supply chains of the textile and leather industries, as well as for consumer protection. Over 21,000 manufacturers, brands, and retailers in more than 100 countries officially work with OEKO-TEX®. With accredited testing and inspection services, the testing service provider Hohenstein as founding member of the OEKO-TEX® Association is the largest provider of certifications, labels and tools that enable companies to act sustainably by protecting people and our planet. The OEKO-TEX® modular system provides the optimal basis for this as it continually refines its standards and is always practically orientated to current market requirements.

For trusted proof of safer textile and leather chemicals, more and more brands and manufacturers are leveraging OEKO-TEX® ECO PASSPORT, which recently reached the landmark 13,000 certified chemical products.

For trusted proof of safer textile and leather chemicals, more and more brands and manufacturers are leveraging OEKO-TEX® ECO PASSPORT, which recently reached the landmark 13,000 certified chemical products.

The significance of ECO PASSPORT

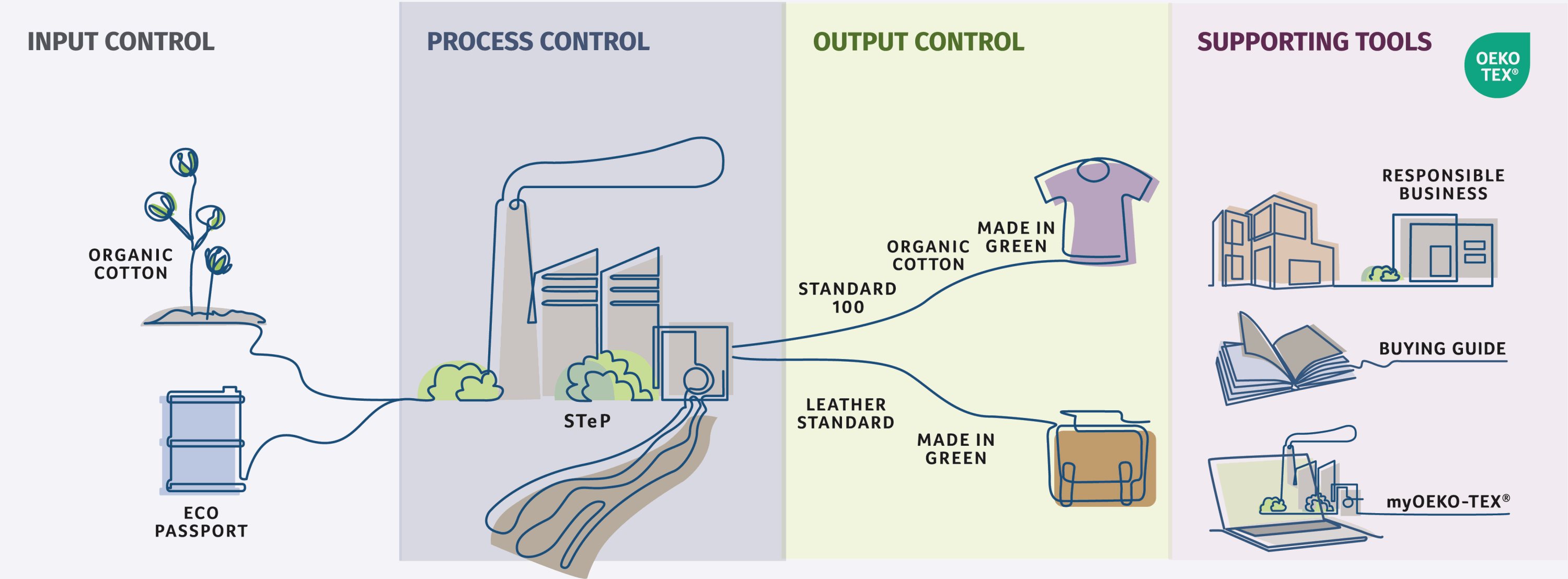

The production of apparel, footwear, textile, and leather is chemically intensive. Input chemistry has a significant effect on product safety, the environment and circularity. Greener chemistry proactively removes hazardous substances before they enter supply chains. It is far more effective than rejecting unsafe finished goods or reversing environmental damage. A testing and certification system enables suppliers to select better chemistry and prevents toxins and impurities from entering factories, products, and ecosystems. OEKO-TEX® ECO PASSPORT targets chemicals, colourants and auxiliaries used to manufacture apparel, footwear, and textile. The multi-stage verification process analyses whether chemical products and individual ingredients meet specific requirements for sustainability, safety, and statutory compliance. The ECO PASSPORT Restricted Substance List (RSL) combines substances restricted through ECO PASSPORT, STANDARD 100, LEATHER STANDARD and STeP, integrating seamlessly with downstream OEKO-TEX® certifications.

Conformance by three-step verification process

ECO PASSPORT certification involves a multi-stage procedure to assess whether each individual substance in a chemical product is not harmful to human health and that it meets statutory requirements.

-

CAS Number Screening:

During the CAS number screening, the testing service provider compares the product components declared by the applicant against the list of harmful chemicals for the ECO PASSPORT (RSL/MRSL) and SVHC Candidate List from REACH. -

Analytical Testing:

Analytical verification in the labs ensures that the certified chemicals can be used in the sustainable production of textiles and leather articles that are safe for human ecology. -

Self-Assessment & On-Site Visit:

An on-site audit (optional) verifies the data submitted by the manufacturer as part of a self-assessment (mandatory) at facility level. Applicants must have systems in place for environmental management, health and safety, quality management and social responsibility.

The OEKO-TEX® modular system provides the optimal basis for sustainable and socially responsible production of textiles and leather articles, as it continuously develops its standards and is always oriented towards current market requirements.

The OEKO-TEX® modular system provides the optimal basis for sustainable and socially responsible production of textiles and leather articles, as it continuously develops its standards and is always oriented towards current market requirements.

ECO PASSPORT aligns with various platforms

ECO PASSPORT ensures compliance with legal requirements, ZDHC MRSL V3.1 levels 1-3 (certification for the ZDHC Chemical to Zero Progressive Level (CtZ-P), fulfils the highest requirements for ZDHC conformity), REACH SVHC list, BHive App from GoBlu, Foursource and other industry initiatives. OEKO-TEX® STeP customers will get easy access to the ZDHC Gateway and the ZDHC Supplier to Zero programme, which will increase their readiness for the OEKO-TEX® STeP certification. Wastewater testing for OEKO-TEX® STeP directly translates into a ZDHC ClearStream, simplifying customer requirements. STeP customers already benefit from the OEKO-TEX® The BHive®’s partnership. It enables customers to digitalise their chemical inventories. Through The BHive® customers can conduct ZDHC Performance InCheck and conformance checks against the ZDHC Gateway, the largest database of chemical products certified against the ZDHC MRSL. ZDHC and OEKO-TEX® are working on establishing data sharing processes that will stand to benefit customers (e.g., in the ECO PASSPORT process and through listing on the ZDHC Gateway). This collaboration will strengthen data quality, making performance and impact evaluation increasingly more credible. In summary, the ZDHC Gateway and BHive App from GoBlu are available for the publication of certified products, including all associated certificates. ECO PASSPORT is a strong part of the sustainable sourcing approaches and corporate social responsibility (CSR) initiatives for a growing number of global brands and retailers.

To learn more, please visit www.hohenstein.com/eco-passport, www.oeko-tex.com or contact customerservice@hohenstein.com.

Discover the latest innovations in sustainable print at FESPA Global Print Expo 2024, Europe’s leading print and signage exhibition. Taking place from 19th – 22nd March 2024 at RAI Amsterdam, Netherlands. Register here to visit.

Topics

Recent news

Green Printing: how Sustainability drives business success

Nessan Cleary shares sustainable printing benefits businesses and the environment. Auditing suppliers and using eco-friendly materials are crucial. Optimising production with energy-efficient equipment and minimising waste reduces costs. Proper waste disposal and premises efficiency further lower the carbon footprint. Staff training and customer recycling solutions complete the sustainable approach.

Sustainability and keeping the faith

Laurel Brunner discusses how the printing industry has drastically reduced its environmental impact through technological advances, despite lingering perceptions of paper waste. While consumer habits pose a challenge, the industry continues to pursue greener practices.

Kyocera wins Anthem Award for Sustainability, Environment and Climate

Laurel Brunner shares how Kyocera, a Japanese manufacturer of digital printing system was awarded a silver award for its green skills report on "A Green Edge: Green Skills for the Future".

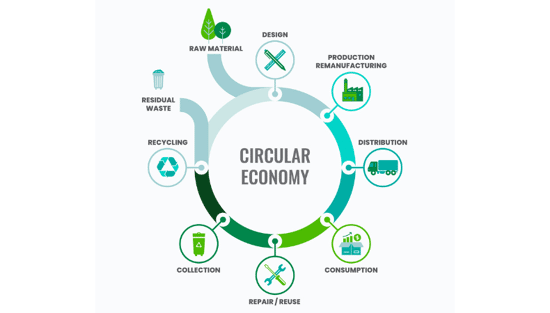

How to design for a circular economy in a linear world

Laurel Brunner explains the challenges for businesses to prioritise circular economy when economies have evolved to be linear. Laurel shares examples of different businesses who are designing products that can suppor the circular economy. These include The Ellen MacArthur Foundation, DS Smith and Vilsund Blue A/S.