How to print on sustainable self-adhesive films

The printing industry is making substantial efforts to become more sustainable. Sustainable self-adhesive film is an important factor. Sonja Angerer shares how to print on films in an environmentally friendly way and what printers can do to become greener.

What about SK film and environmental protection? The answer is not simple, because the two are not always compatible. But for many areas of digital printing and sign-making, adhesive films are indispensable, for example for window and floor graphics or vehicle wrapping. That's why they make up between 25% - 33% of the printed material in many print shops. What is the challenge with sustainable self-adhesive film and what options do printers have to overcome it?

Films and the PVC problem

Most of the plastics used globally such as polyethylene (PE), polypropylene (PP) and polyvinyl chloride (PVC or vinyl), are based on fossil raw materials. The Federal Environment Agency warns against the use of PVC because this plastic can release toxic dioxin when burned.

According to a study commissioned by the industry associations PlasticsEurope and Vinyl Plus, almost 70% of the post-consumer waste generated by PVCs in Germany is "thermally recycled", i.e. incinerated.

PVC also contains plasticizers, which are easily released into the environment and can also seriously affect human health. Regardless of this, many films for digital printing are made of PVC.

PVC production is highly efficient as the energy required is low and raw materials are cheap. The substrate also is highly versatile and durable. In digital printing, there is yet another important factor: As PVC substrates are so common, many print heads and inks are clearly optimised for printing onto it.

CAPTION: For some PVC-free self-adhesive films, such as 3M Envision Print Wrap Films, there is also a protective laminate to go with it available. Image Credit: 3M

CAPTION: For some PVC-free self-adhesive films, such as 3M Envision Print Wrap Films, there is also a protective laminate to go with it available. Image Credit: 3M

Alternative self-adhesive films, liners, and adhesives

Vinyl-free alternatives, such as the Spandex Image Perfect EverGreen series, often use polypropylene (PP) or polyethylene (PET) instead of PVC. Sometimes, manufacturers of green self-adhesive film also rely on plastics made from renewable or already recycled resources.

Self-adhesive films consist of at least 3 components: carrier material, adhesive and masking paper (liner). The base material is often primed, for example with an ink absorbing layer. For fire-resistant films according to EN 13501-1:2019, such as GreenFilm 100 PP LUVESS M W ultra tack air adh FR from Com2C, another coating must be applied.

While liners, which are typically silicone-coated paper cause more waste for businesses, solvent-based glue on SK films can also lead to serious issues for humans and the planet, as many highly volatile solvents (VOCs) are known to be hazardous and contribute to further damaging the environment.

That's why Avery Dennison has launched the patented, solvent-free adhesive iA Tech. It requires less fossil raw material than currently used glue formulations for self-adhesive printing materials. The product is already being used for the 777 Cast film series.

CAPTION: The green self-adhesive Igepa MasterJet E 200 Trend does not contain PVC. Image Credit: Igepa

CAPTION: The green self-adhesive Igepa MasterJet E 200 Trend does not contain PVC. Image Credit: Igepa

Sustainable self-adhesive film and recycling

To recover any raw materials, they must be as free of paint or ink as possible and collected according to type. When using self-adhesive films in the digital printing, there are 3 fundamental problems:

-

Deinking

-

Composites

-

Waste collection

Depending on the formulation, digital printing ink behaves differently on a plastic substrate: solvent-based and eco-solvent ink penetrates the PVC. This makes the print highly weather resistant. Latex inks polymerize on the surface, UV-curing inks form a bond. As a result, the prints are inseparable from the substrate. This means the inks cannot be removed with currently used deinking methods.

For many common applications, such as vehicle wrapping or floor graphics, digitally printed self-adhesive films must be provided with a protective laminate. Products made of several materials that are not easily separable are considered composites. They are to be disposed of in waste incineration plants or landfills.

Production waste and dismantled films must be collected and labelled separately according to carrier film so that sorted processing is efficient. For printers, assembly staff and advertising customers, this means increased effort. In addition, it can be difficult for professionals to correctly identify the base layer plastic type if the relevant information is no longer available.

CAPTION: Spandex's PVC-free ImagePerfect EverGreen 9500 self-adhesive film can last up to 5 years outdoors. Image Credit: Spandex.

CAPTION: Spandex's PVC-free ImagePerfect EverGreen 9500 self-adhesive film can last up to 5 years outdoors. Image Credit: Spandex.

What can printers do to print greener?

The complex situation regarding film can be overwhelming for printers when it comes to sustainable printing. In fact, it is not easy to develop green self-adhesive films.

After all, the use of a PVC-free or recycled substrate does not yet constitute a sustainable self- adhesive film. This is especially true because local or commercial waste disposal companies and their ability to separate and process raw materials can vary significantly.

However, there are a few relatively easy-to-implement actions that can make a significant difference:

-

Avoid PVC where possible and effective

-

Use of energy-efficient printing and finishing machines

-

Minimising logistics and packaging

-

Avoid waste during production

Another very effective method is the use of the correct laminate. This way, it is possible to avoid the production of more poorly recyclable composite materials. There is protective laminate for green and PVC-free self-adhesive films such as Igepa MasterJet Trend or 3M Envision Print Wrap Films readily available to the market.

Ultimately, however, significant progress towards greater sustainability in self-adhesive film printing will only be possible if all suppliers in the digital printing industry and printers work together. After all, if the entire life cycle is considered already during product development, further processing and recycling can be much easier. This will also facilitate the engagement of print buyers and removes any suspicion of greenwashing in green self-adhesive films.

Topics

Recent news

Green Printing: how Sustainability drives business success

Nessan Cleary shares sustainable printing benefits businesses and the environment. Auditing suppliers and using eco-friendly materials are crucial. Optimising production with energy-efficient equipment and minimising waste reduces costs. Proper waste disposal and premises efficiency further lower the carbon footprint. Staff training and customer recycling solutions complete the sustainable approach.

Sustainability and keeping the faith

Laurel Brunner discusses how the printing industry has drastically reduced its environmental impact through technological advances, despite lingering perceptions of paper waste. While consumer habits pose a challenge, the industry continues to pursue greener practices.

Kyocera wins Anthem Award for Sustainability, Environment and Climate

Laurel Brunner shares how Kyocera, a Japanese manufacturer of digital printing system was awarded a silver award for its green skills report on "A Green Edge: Green Skills for the Future".

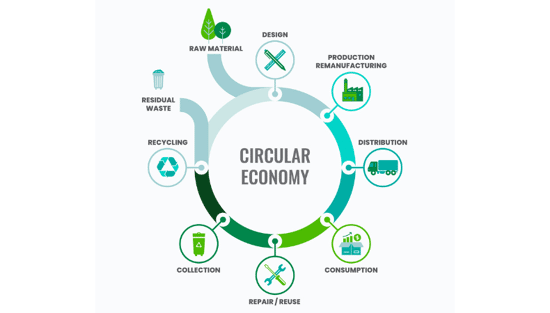

How to design for a circular economy in a linear world

Laurel Brunner explains the challenges for businesses to prioritise circular economy when economies have evolved to be linear. Laurel shares examples of different businesses who are designing products that can suppor the circular economy. These include The Ellen MacArthur Foundation, DS Smith and Vilsund Blue A/S.