Mimaki Engineering launches eco-friendly carbon ink cartridges to worldwide market

Mimaki launches eco-friendly carton ink cartridges to the global printing industry, significantly reducing plastic usage and improving recyclability This latest solution is another initiative by the company to support printers in reducing their environmental impact

Mimaki Engineering Co. Ltd., a leading manufacturer of industrial inkjet printers, cutting plotters, and 3D printers have launched its eco-friendly carton ink cartridges to the global printing industry. These cartridges have replaced traditional plastic cartridges with an environmentally friendly paper alternative, marking an important shift towards sustainability in the printing industry.

The carton ink cartridges were initially introduced to the Japanese market in May 2023, and has now been launched to the rest of the world and will be launched in the EMEA market this summer. These cartridges have been designed to be used in Mimaki’s eco-solvent printers, these cartridges retain exceptional performance while significantly reducing environmental impact.

By transitioning from plastic to paper, Mimaki has achieved a 68% reduction in plastic usage per cartridge. This approach is estimated to eliminate approximately 44 tons of plastic and 65 tons of CO2 emissions each year. The lighter weight of carton ink cartridges translates to an estimated 8-ton reduction in CO2 emissions during transportation, further contributing to a decarbonised society.

The ink cartridge received the Industrial Packaging Category Award at the 2023 Japan Packaging Contest.

Innovating for a Greener Future

In alignment with the Sustainable Development Goals (SDGs), Mimaki continues to strive for resource-recycling management and technology.

Mimaki are also working towards sustainable solutions across various sectors. The latest innovations include:

-

Neo-Chromato Process: This innovative technology facilitates material recycling, leading to a significant reduction in CO2 emissions through the reuse of textile materials.

-

TRAPIS: The textile printing pigment transfer system provides printing on fabrics without the need for specialised techniques or expertise. This promotes efficiency and sustainability in textile production.

-

M2COA: An automated packaging system for industrial product printing, which addresses labour shortage issues in the print service business by streamlining operations.

In addition to these solutions, since March 2024 Mimaki has implemented environmental measures such as reducing cushioning material in 2L ink packs across all ink-producing plants.

Arjen Evertse, General Manager Sales EMEA at Mimaki Europe commented: “We remain committed to innovation in all parts of the production process, from the ink cartridges to the technology itself, in pursuit of a positive environmental impact. To respond swiftly to social and environmental needs, we see the importance of advanced technologies such as automation, high-efficiency and high-speed printers, and waterless textile technology. Through all these sustainable initiatives, we continue to be dedicated in making a positive contribution to the global print community and fostering a sustainable future for generations to come.”

For more information on Mimaki’s ongoing sustainability initiatives, visit here.

To stay up to date with the latest news within the print industry which covers a wide range of topics such as inks and sustainability sign up for FESPA’s free monthly newsletter FESPA World available in English, Spanish and German.

Recent news

Green Printing: how Sustainability drives business success

Nessan Cleary shares sustainable printing benefits businesses and the environment. Auditing suppliers and using eco-friendly materials are crucial. Optimising production with energy-efficient equipment and minimising waste reduces costs. Proper waste disposal and premises efficiency further lower the carbon footprint. Staff training and customer recycling solutions complete the sustainable approach.

Sustainability and keeping the faith

Laurel Brunner discusses how the printing industry has drastically reduced its environmental impact through technological advances, despite lingering perceptions of paper waste. While consumer habits pose a challenge, the industry continues to pursue greener practices.

Kyocera wins Anthem Award for Sustainability, Environment and Climate

Laurel Brunner shares how Kyocera, a Japanese manufacturer of digital printing system was awarded a silver award for its green skills report on "A Green Edge: Green Skills for the Future".

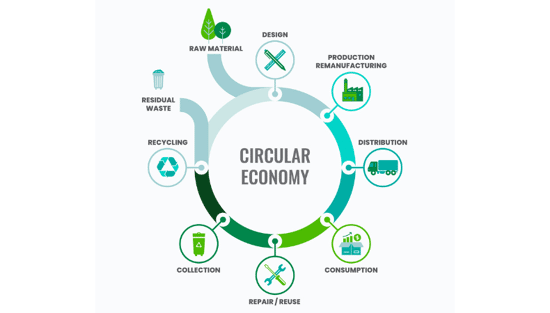

How to design for a circular economy in a linear world

Laurel Brunner explains the challenges for businesses to prioritise circular economy when economies have evolved to be linear. Laurel shares examples of different businesses who are designing products that can suppor the circular economy. These include The Ellen MacArthur Foundation, DS Smith and Vilsund Blue A/S.